Method for producing a brake lining carrier

A technology of brake linings and disc brakes, which is applied in the direction of brake components, friction linings, brake types, etc., can solve problems such as breakage of brake lining brackets, and achieve the effect of improving retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

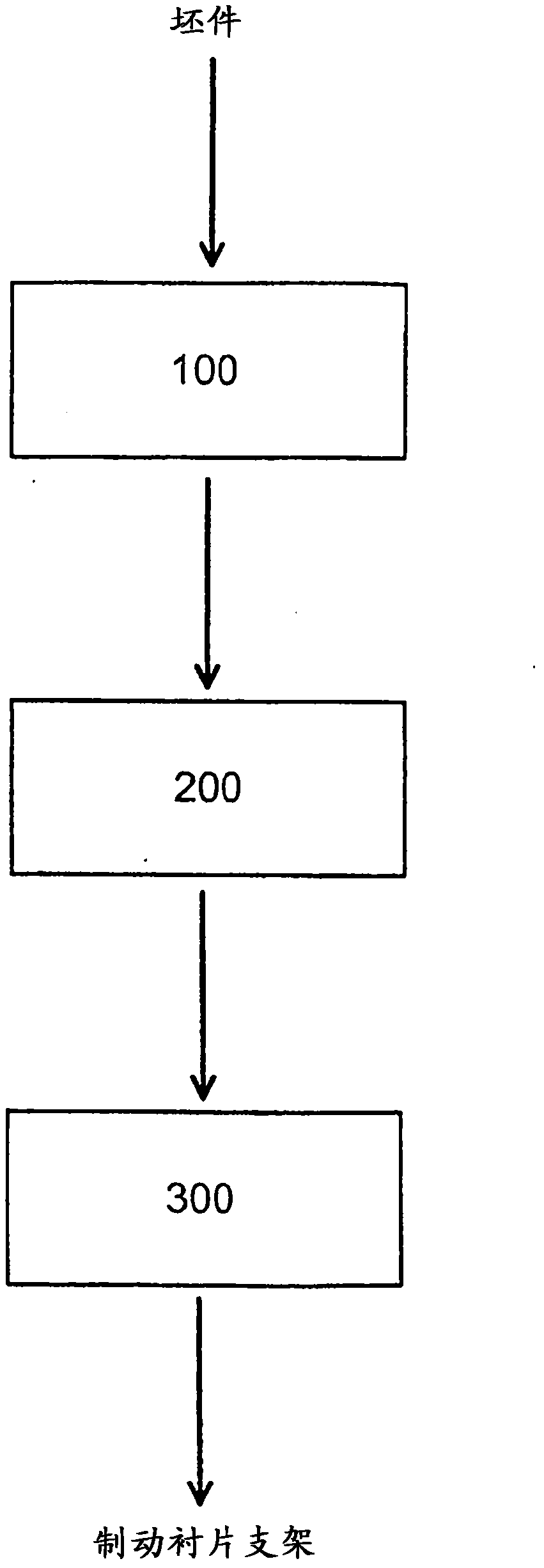

[0038] according to figure 1 In the embodiment shown in , firstly a blank made of steel plate is provided as workpiece. In method step 100, the blank is conveyed to the machine for use in the horizontal working direction ( Figure 8 In the plane of the drawing) a workstation 30 for upsetting an edge section of a blank, more precisely for producing a material thickening of predetermined dimensions on the edge side. Figure 8 The arrangement of the workstations 30 on the lower processing part 20 of the processing device is shown schematically. Sections of the edge of the workpiece are forged by means of the workstation 30 in a direction transverse to, in particular perpendicular to, the drawing direction (perpendicular to the plane of the drawing). At the same time, the workpiece is perforated at a predetermined position and is provided with an edge-side recess to be arranged at a predetermined position for arranging a wear indicator ( Figure 8 not shown).

[0039] Four rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com