Organic EL element

一种元件、有机的技术,应用在有机电致发光元件领域,能够解决功耗增大、无法制作显示器、难以确保掩模对位精度等问题,达到空穴注入效率高、优异发光效率、实现性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0119] (Structure of organic EL element)

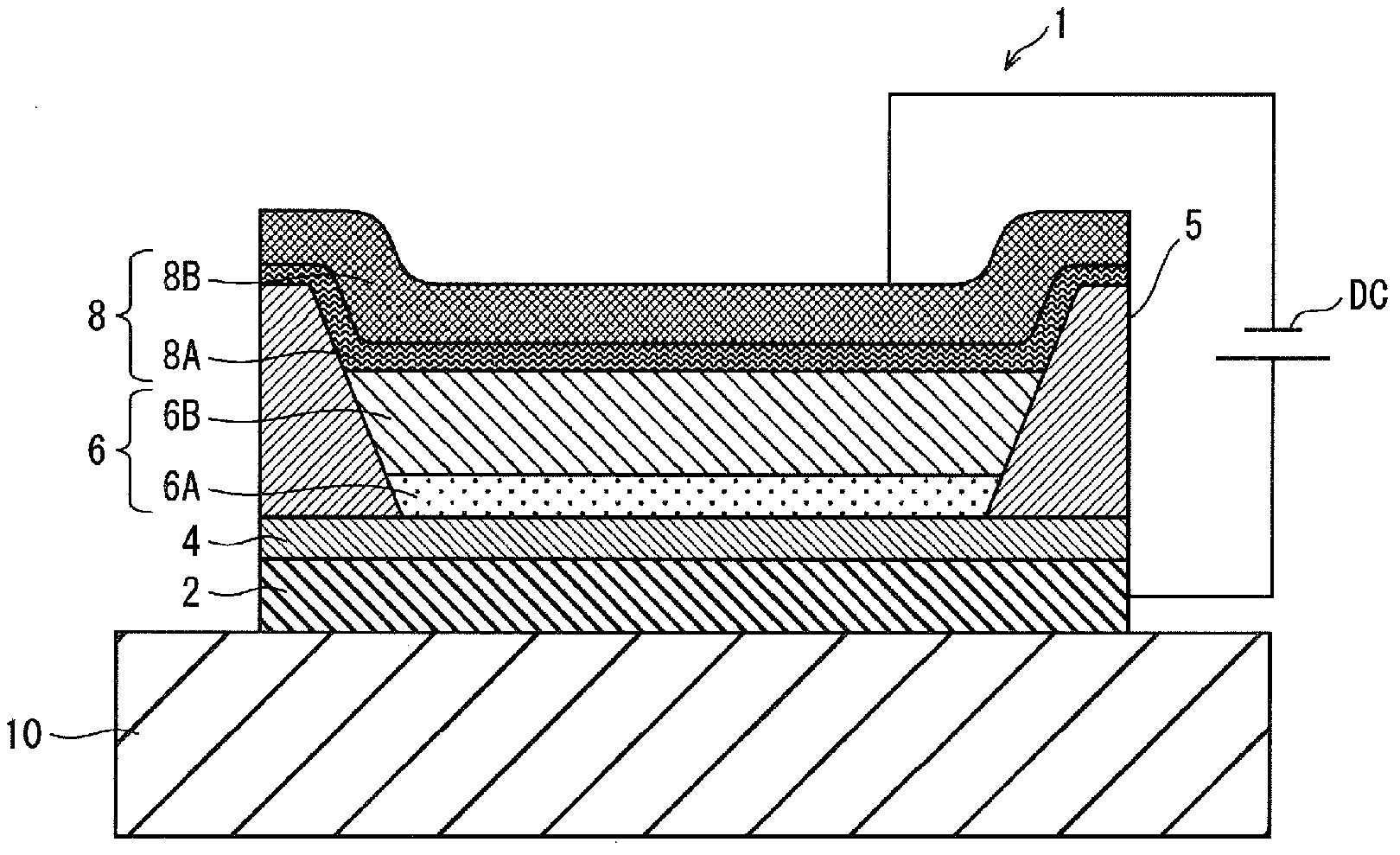

[0120] figure 1 It is a schematic cross-sectional view showing the structure of the organic EL element 1 of the first embodiment.

[0121] The organic EL element 1 is a coating type in which a functional layer is formed by coating by a wet process, and has a structure in which a hole injection layer 4 and various functional layers (here, a buffer layer 6A and a light emitting layer 6B) are placed on top of each other. Interposed between the electrode pair consisting of the anode 2 and the cathode 8 in a stacked state, the various functional layers include organic materials having predetermined functions.

[0122] Specifically, as figure 1 As shown, the organic EL element 1 is formed by stacking an anode 2, a hole injection layer 4, a buffer layer 6A, a light emitting layer 6B, and a cathode 8 (a barium layer 8A and an aluminum layer 8B) on one main surface of a substrate 10 in the following order. constituted. A power supply DC is...

Embodiment approach 2

[0335]

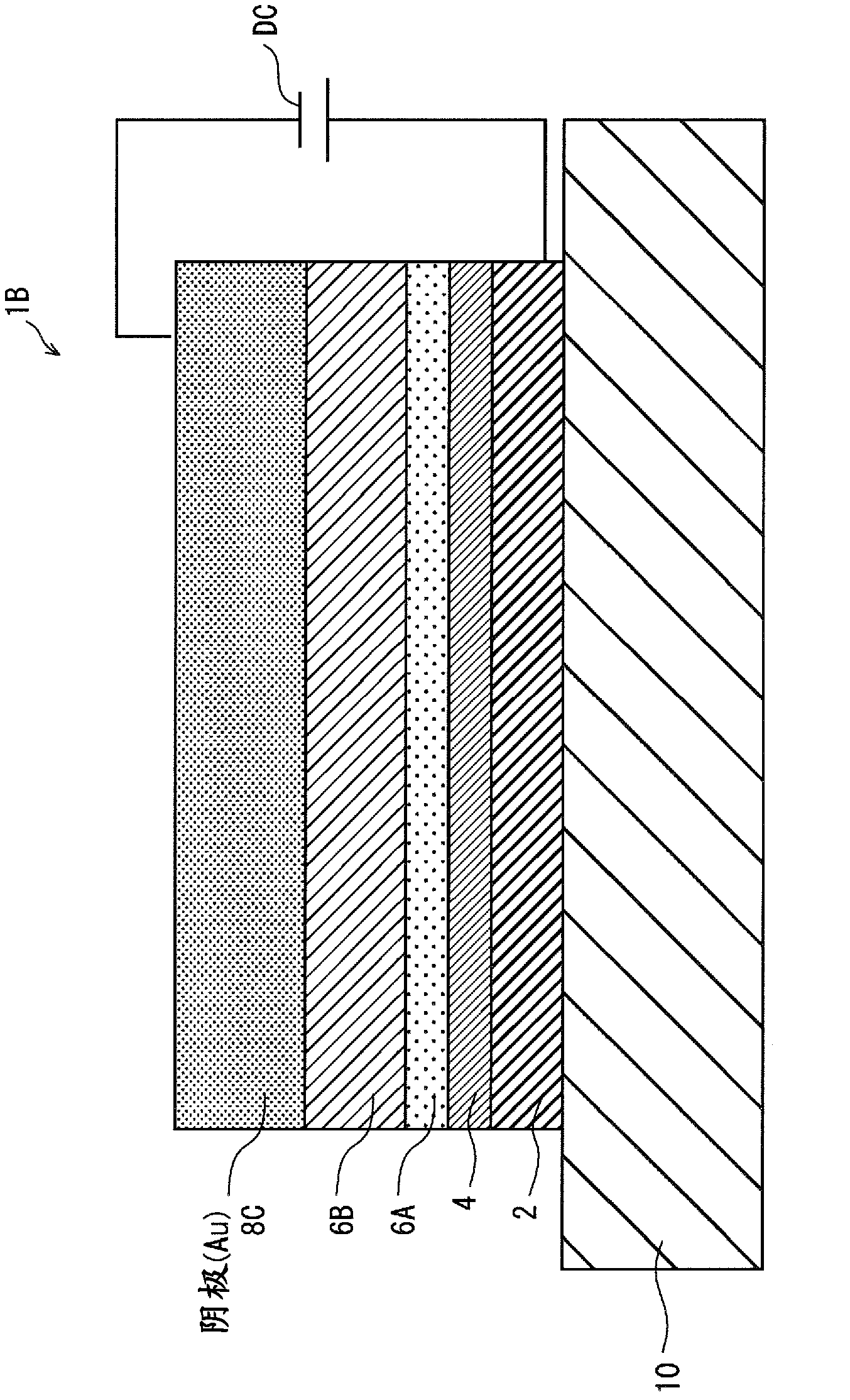

[0336] Figure 25 (a) is a schematic cross-sectional view showing the structure of the organic EL element 1C according to the present embodiment. Figure 25 (b) is a partially enlarged view near the hole injection layer 4A.

[0337] The organic EL element 1C is, for example, a coating type in which a functional layer is formed by coating by a wet process, and has a structure in which a hole injection layer 4 and various functional layers are stacked on each other between the anode 2 and the Between the pair of electrodes constituted by the cathode 8D, the various functional layers include organic materials having predetermined functions.

[0338] Specifically, in the organic EL element 1C, an anode 2, an ITO layer 3, a hole injection layer 4A, a buffer layer 6A, a light emitting layer 6B, an electron injection layer 7, and a cathode 8D are laminated on one main surface of a substrate 10 in the following order. , Sealing layer 9 and constitute. The following descr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com