Processing method of pan-fired green tea

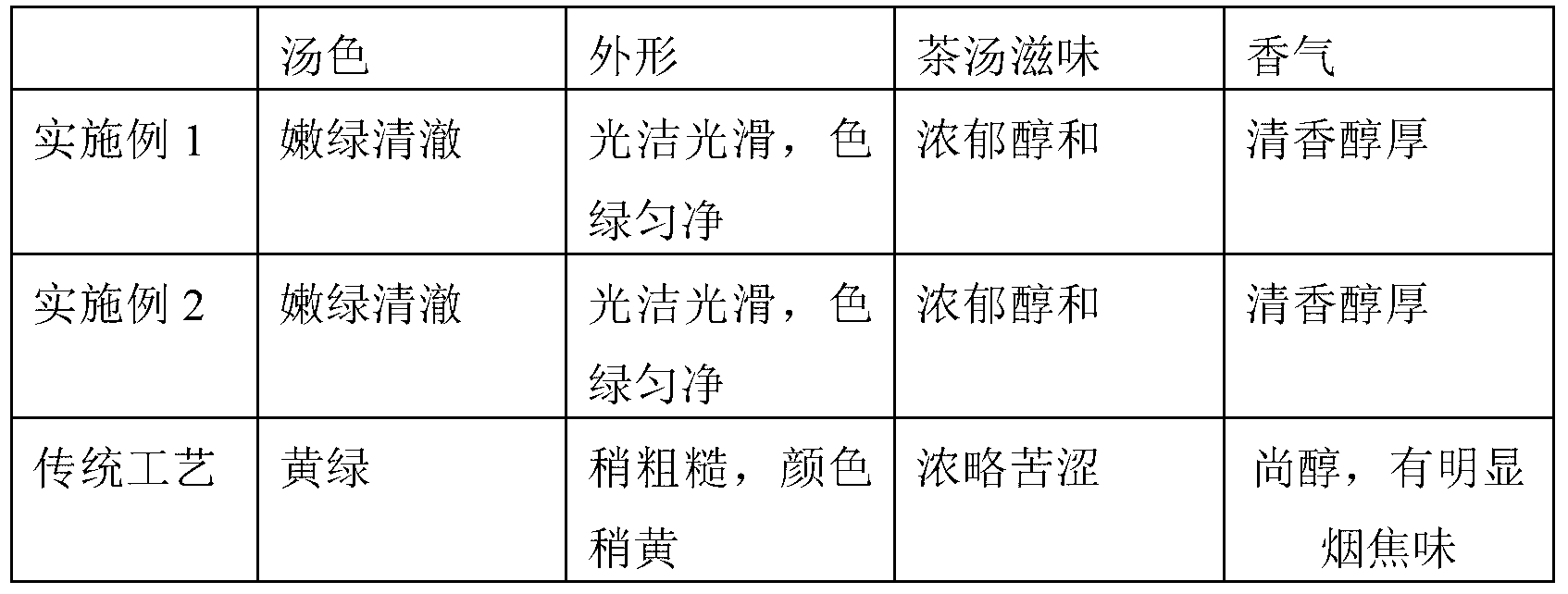

A processing method and green tea technology, which are applied in the processing field of fried green tea, can solve the problems of heavy bitterness and astringency, and the color of fried green tea is not green enough, and achieve the effects of pure aroma, green and clear soup, and mellow taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A processing method of fried green tea, comprising the following steps:

[0018] (1) Picking of fresh leaves: Picking one bud with two leaves, one bud with three leaves, or pairs with two leaves of the same tenderness;

[0019] (2) Spreading of fresh leaves: Spread the picked fresh leaves on a clean bamboo plaque at 18°C for 8 hours, with a thickness of 4cm, and turn over every 2 hours;

[0020] (3) Finishing: use 6CS--120 bottle-type rotary drum cleaning machine, put the fresh leaves spread in step (2) at 200 ° C, the amount of leaves is 4kg per pot, the killing time is 3min, and get off the machine let cool to room temperature;

[0021] (4) Kneading: Use a 40-type kneading machine to knead the cooled green leaves for 20 minutes. The degree of kneading depends on the tea juice adhering to the leaf surface, and the hand feels lubricated and sticky;

[0022] (5) Drying: Use a dryer to dry, and when the moisture content is lower than 8%, take it off the machine and le...

Embodiment 2

[0024] A processing method of fried green tea, comprising the following steps:

[0025] (1) Picking of fresh leaves: Picking one bud with two leaves, one bud with three leaves, or pairs with two leaves of the same tenderness;

[0026] (2) Spread fresh leaves: spread the picked fresh leaves on a clean bamboo plaque at 25°C for 5 hours, with a thickness of 2 cm, and turn over every 2 hours;

[0027] (3) Finishing: use 6CS--120 bottle-type rotary drum cleaning machine, put the fresh leaves spread in step (2) at 240 ° C, the amount of leaves is 6kg per pot, the killing time is 2min, and get off the machine let cool to room temperature;

[0028] (4) Kneading: Use a 40-type kneading machine to knead the cooled green leaves for 30 minutes. The degree of kneading depends on the tea juice adhering to the leaf surface, and the hand feels lubricated and sticky;

[0029] (5) Drying: Use a dryer to dry, and when the moisture content is lower than 8%, take it off the machine and let it co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com