Foam basketball production method and foam basketball

A production method and basketball technology, which are applied to balls, inflatable hollow balls, sports accessories, etc., can solve the problems of poor bounce, poor impact wear resistance, poor strength, etc., and achieve a simple production process, The effect of good air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings.

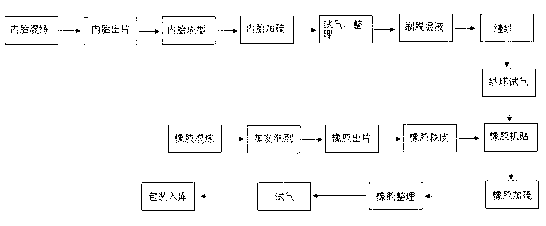

[0016] figure 1 It is a schematic flow diagram of a foamed basketball manufacturing method according to a specific embodiment of the present invention, such as figure 1 As shown, the foamed basketball manufacturing method of the present invention includes the following steps:

[0017] a) Making the inner tube: the colloid is mixed, sheeted, and spliced to form a spherical inner tube of the required size, and then vulcanized and shaped, and the formed inner tube is tested and finished;

[0018] b) Making the yarn winding layer: Brush the delaminating liquid on the outer surface of the finished inner tube, and then wind the yarn around the spherical surface of the inner tube, so that the yarn is evenly wound to cover the spherical surface of the entire inner tube to obtain a yarn ball, and test the air of the formed yarn ball , Finishing, the type of winding yarn used in the winding lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com