Rapid measurement system and error compensation method for five-coordinate CNC machine tool swing angle

A technology of numerical control machine tools and compensation methods, which is applied in the direction of measuring/indicating equipment, metal processing machinery parts, other manufacturing equipment/tools, etc., can solve the problems of unable to realize automatic measurement, unable to realize compensation calculation, unable to meet measurement requirements, etc., to achieve Convenient and fast positioning accuracy, reducing equipment maintenance costs, and saving external employment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

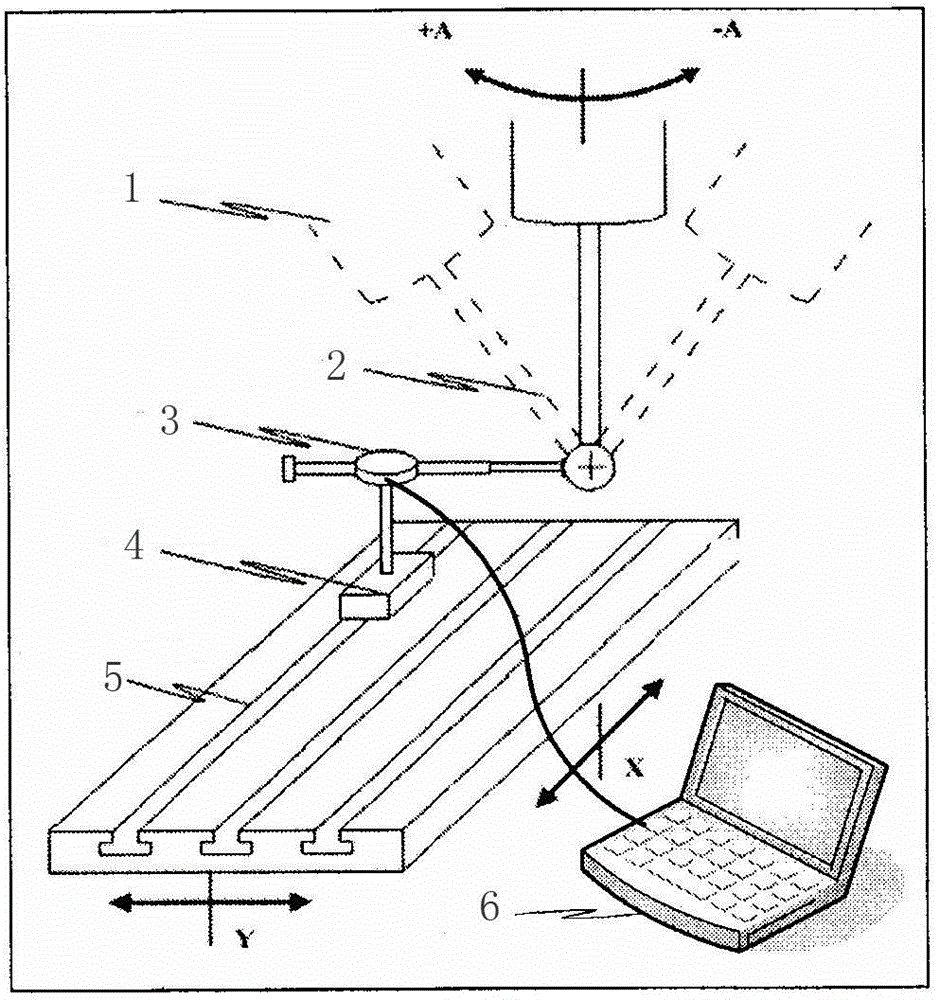

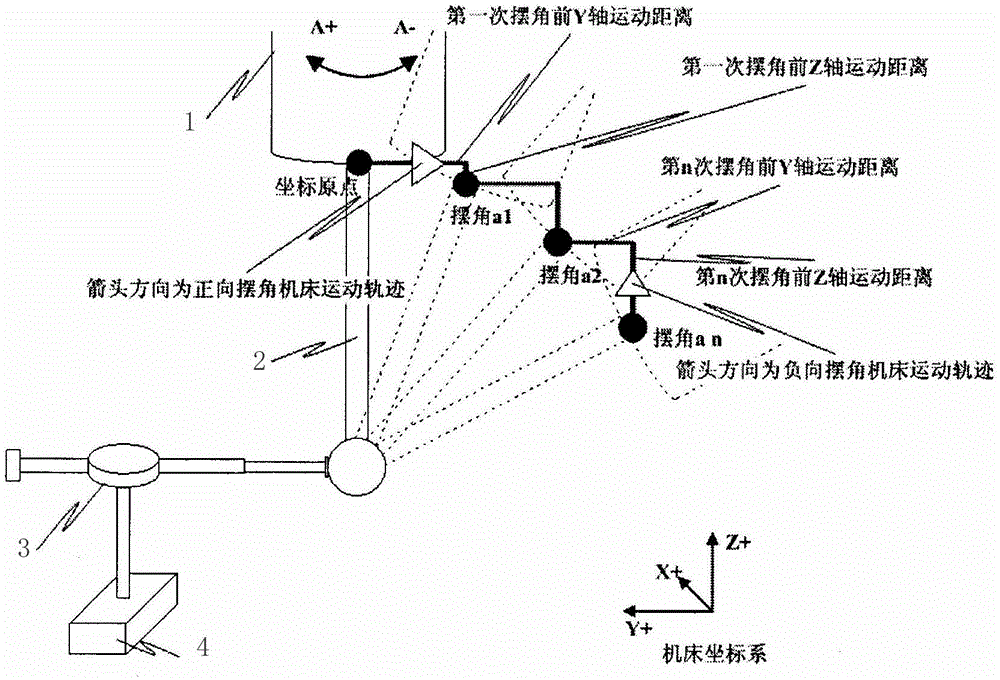

[0036] like figure 1 As shown, a measurement system for the positioning accuracy of the swing angle of a five-coordinate numerical control machine tool includes a ball mandrel 2, a digital display dial indicator 3 and a magnetic base 4, wherein the ball mandrel 2 is installed on the machine tool spindle 1, The digital display dial indicator 3 is installed on the magnetic base 4, and the magnetic base 4 is fixed on the machine tool workbench 5. The digital display dial indicator 3 is located at a positive position perpendicular to the machine tool spindle 1, and the digital display dial indicator 3 The measuring head of the machine tool is attached to the spindle 1 of the machine tool, and the digital display dial gauge 3 is connected to the computer terminal 6 .

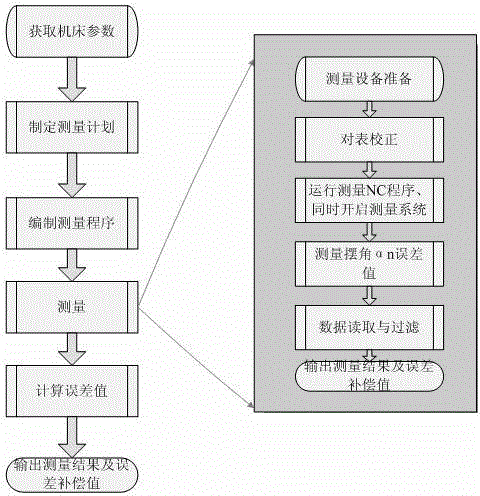

[0037] like figure 2 As shown, the following uses a MAG five-coordinate machining center to measure the A-axis as an example to specifically illustrate a calculation and compensation method for the measurement err...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com