Filling machine for amoxicillin sodium and sulbactam sodium medicine powder used for injection

A technology for amoxicillin sodium and sulbactam sodium and injection is applied in the field of medicine powder filling machines for amoxicillin sodium and sulbactam sodium for injection, which can solve the problems of high price, wide area and large volume, etc. achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

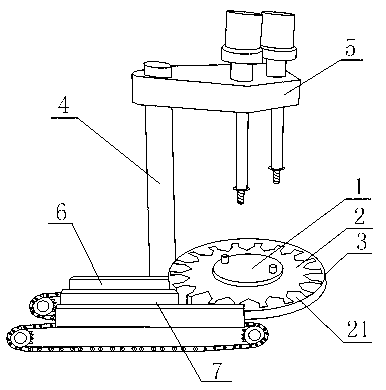

[0018] Such as figure 1 A medicine powder filling machine for amoxicillin sodium and sulbactam sodium for injection is shown, which includes an operating table, a rotating device 1 fixed on the operating table, and a medicine bottle fixing plate 2 fixed on the rotating device 1 , the four sides of the medicine bottle fixed disk 2 are provided with grooves 21, and the outside of the described medicine bottle fixed disk 2 is provided with a circle of binding plate 3. There is a base plate at the bottom of the described medicine bottle fixed disk 2, and the bottom plate A medicine bottle output device 6 and a medicine bottle input device 7 are provided, and the said binding plate 3 and the bottom plate are all provided with an output port and an input port, and the described output port and the input port are connected with the medicine bottle output device 6 and the medicine bottle respectively. The position of the input device 7 is corresponding, and the medicine powder filling...

Embodiment 2

[0020] This embodiment is basically the same as Embodiment 1, the difference is: in order to simplify the structure of the medicine bottle output device 6 and the medicine bottle input device 7, the described medicine bottle output device 6 and the medicine bottle input device 7 both include two chains Wheels and chains matching the sprockets.

[0021] Further, a sprocket of the medicine bottle output device 6 and the medicine bottle input device 7 is respectively located below the output port and the input port on the bottom plate.

[0022] In order to make the radian of each rotation of the medicine bottle fixed disk 2 consistent, the grooves 21 are multiple and evenly distributed around the medicine bottle fixed disk 2 .

[0023] The rotating device is located at the center of the medicine bottle fixed disk 2 .

[0024] The powder filling device 5 includes a filling device and a capping device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com