Concrete additive and preparation method thereof

A concrete admixture and retarder technology, which is applied in the field of engineering materials and its preparation, can solve the problems of long demolition time, low strength, and increased engineering costs, and achieve shortened demolition time, improved use efficiency, and reduced workload Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

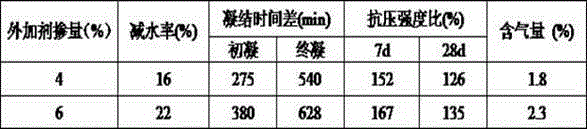

Embodiment 1

[0031] 1. Preparation of water reducing agent

[0032] (1) Weigh 14 parts of sodium p-aminobenzenesulfonate, 2.2 parts of dicyandiamide, 6.0 parts of bisphenol A, 18 parts of formalin, 0.3 parts of tartaric acid, 0.7 parts of sodium hydroxide, 3.8 parts of phenol, and 55 parts of water ;

[0033] (2) Add the weighed sodium p-aminobenzenesulfonate, dicyandiamide, bisphenol A, tartaric acid, phenol and water into the reaction kettle, stir evenly, and when the pH value of the reaction system is 3.0 to 5.0, heat up to 85~100℃;

[0034] (3) When the temperature reaches 85~100°C, stir the material in the reaction kettle evenly, add formalin dropwise within 2.0h, and continue heating for 2.8h;

[0035] (4) Adjust the pH value to 8.0~9.0 with sodium hydroxide, and react at a temperature of 85~100°C for 4.5h;

[0036] (5) Use sodium hydroxide to adjust the pH value to 10.0~12.5, react at 85~100°C for 3 hours, then cool down and discharge to obtain a reddish-brown liquid, which is sp...

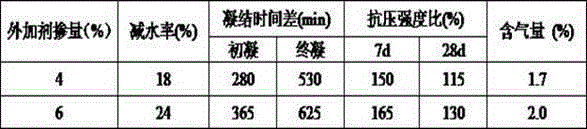

Embodiment 2

[0051] 1. Preparation of water reducing agent

[0052] (1) Weigh 16 parts of sodium p-aminobenzenesulfonate, 2.0 parts of dicyandiamide, 5.9 parts of bisphenol A, 18.2 parts of formalin, 0.3 parts of tartaric acid, 0.8 parts of sodium hydroxide, 2.8 parts of phenol, and 54 parts of water ;

[0053] (2) Add the weighed sodium p-aminobenzenesulfonate, dicyandiamide, bisphenol A, tartaric acid, phenol and water into the reaction kettle, stir evenly, and when the pH value of the reaction system is 3.0 to 5.0, heat up to 85~100℃;

[0054] (3) When the temperature reaches 85~100°C, stir the material in the reaction kettle evenly, add formalin dropwise within 2.3h, and continue heating for 2.8h;

[0055] (4) Adjust the pH value to 8.0~9.0 with sodium hydroxide, and react at a temperature of 85~100°C for 5.0h;

[0056] (5) Use sodium hydroxide to adjust the pH value to 10.0~12.5, react at 85~100°C for 3 hours, then cool down and discharge to obtain a reddish-brown liquid, which is ...

Embodiment 3

[0071] 1. Preparation of water reducing agent

[0072] (1) Weigh 18 parts of sodium p-aminobenzenesulfonate, 2.0 parts of dicyandiamide, 6.0 parts of bisphenol A, 19.0 parts of formalin, 0.4 parts of tartaric acid, 0.8 parts of sodium hydroxide, 3.0 parts of phenol, and 50.8 parts of water ;

[0073] (2) Add the weighed sodium p-aminobenzenesulfonate, dicyandiamide, bisphenol A, tartaric acid, phenol and water into the reaction kettle, stir evenly, and when the pH value of the reaction system is 3.0 to 5.0, heat up to 85~100℃;

[0074] (3) When the temperature reaches 85~100°C, stir the material in the reaction kettle evenly, add formalin dropwise within 2.5h, and continue heating for 3.0h;

[0075] (4) Adjust the pH value to 8.0~9.0 with sodium hydroxide, and react at a temperature of 85~100°C for 5.0h;

[0076] (5) Use sodium hydroxide to adjust the pH value to 10.0~12.5, react at 85~100°C for 3 hours, then cool down and discharge to obtain a reddish-brown liquid, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com