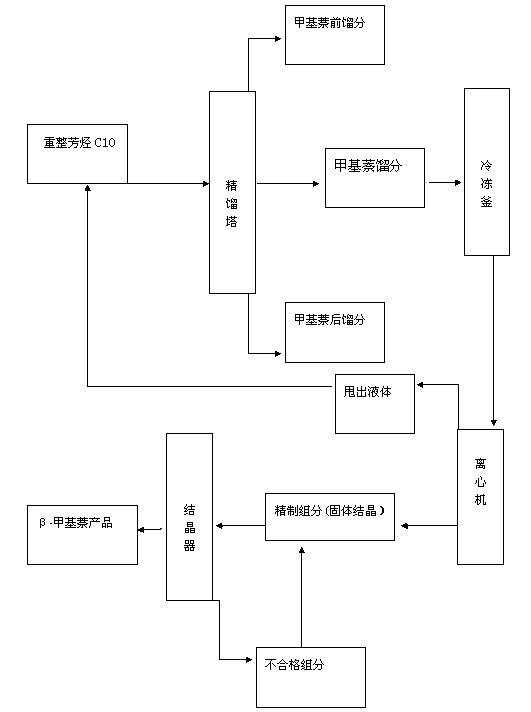

Process method for extracting high-purity beta-methylnaphthalene from reformed aromatic hydrocarbon C10

A methylnaphthalene, high-purity technology, applied in chemical instruments and methods, purification/separation of hydrocarbons, hydrocarbons, etc., can solve the problems of low yield, high cost, complex process, etc., and achieve high product purity and cost. Low and high economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

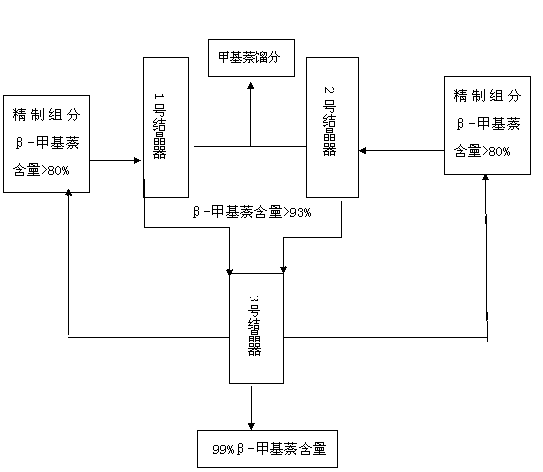

[0025] will reform aromatics C 10 50t of raw materials are continuously passed into the rectification tower with corrugated screen high-efficiency packing (model CY-700Y), the vacuum degree is controlled at 0.095Mpa, and the methylnaphthalene fraction is obtained at the top of the tower, with a distillation range of 235 - 254°C, β-methylnaphthalene content 53.4156wt%, α - The content of methylnaphthalene is 26.1324wt%, and the content of naphthalene is 0.2328wt%. - Between 5°C, the refined components are obtained by separating them with a centrifuge, the content of β-methylnaphthalene is 82.2567wt%, and the refined components are passed into a continuous multi-stage countercurrent fractional crystallizer, and the crystallization temperature is - Between 35°C, 1.52t of finished β-methylnaphthalene was obtained after refining, the content of β-methylnaphthalene was 99.2461wt%, and the yield of β-methylnaphthalene was 22.79%.

[0026] Among them: the refined components are pass...

Embodiment 2

[0028] will reform aromatics C 10 50t of raw materials are continuously passed into the rectification tower with corrugated wire mesh high-efficiency packing (model CY-700Y), the vacuum degree is controlled at 0.095Mpa, and the methylnaphthalene fraction is obtained at the top of the tower, with a distillation range of 237 - 255°C, β-methylnaphthalene content 55.0937wt%, α - The content of methylnaphthalene is 25.7332wt%, and the content of naphthalene is 0.1841wt%. - Between 10°C, the refined components are obtained by centrifuge separation, the content of β-methylnaphthalene is 83.4622wt%, and the refined components are passed into a continuous multi-stage countercurrent fractional crystallizer, and the crystallization temperature is 23 - Between 33°C, 1.61t of finished β-methylnaphthalene was obtained after refining, the content of β-methylnaphthalene was 99.073wt%, and the yield of β-methylnaphthalene was 24.14%.

Embodiment 3

[0030] will reform aromatics C 10 50t of raw material is continuously passed into the rectification tower with corrugated wire mesh high-efficiency packing (model CY-700Y), the vacuum degree is controlled at 0.095Mpa, and the methylnaphthalene fraction is obtained at the top of the tower, with a distillation range of 236 - 253°C, β-methylnaphthalene content 54.232wt%, α - The content of methylnaphthalene is 27.5347wt%, and the content of naphthalene is 0.1966wt%. - Between 10°C, the refined component was obtained by centrifuge separation, the content of β-methylnaphthalene was 83.2531wt%, and the refined component was passed into a continuous multi-stage countercurrent fractional crystallizer, and the crystallization temperature was 22 - Between 34°C, 1.58t of finished β-methylnaphthalene was obtained after refining, the content of β-methylnaphthalene was 99.1463wt%, and the yield of β-methylnaphthalene was 23.69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com