Method of separating anthocyanin from purple highland barley

A technology of anthocyanin and purple, which is applied in the field of extraction of natural pigment anthocyanin, can solve problems such as waste, and achieve the effects of improving utilization rate, reducing damage, and delaying aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The present invention separates the method for anthocyanin from purple highland barley, comprises the following steps:

[0032] 1) Select clean purple highland barley without deterioration and mildew, and use peeling machine peeling technology to collect the outer skin part of purple highland barley;

[0033] 2) Crush the purple highland barley bark, and carry out micro-grinding treatment, so that the particle size is between 0.1-0.2mm;

[0034] 3) Add water equal to the weight of the purple highland barley skin to the purple highland barley skin, then add citric acid to adjust the pH to 3.5, and soak at 20°C for 2 hours;

[0035] 4) Add 70% ethanol solution to the soaked purple highland barley bark at a mass ratio of 1:1 to extract 3 times, each time for 2 hours, filter, combine the filtrate, and then place it at room temperature for 2 hours at 30°C to obtain the extract;

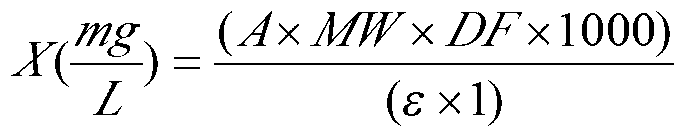

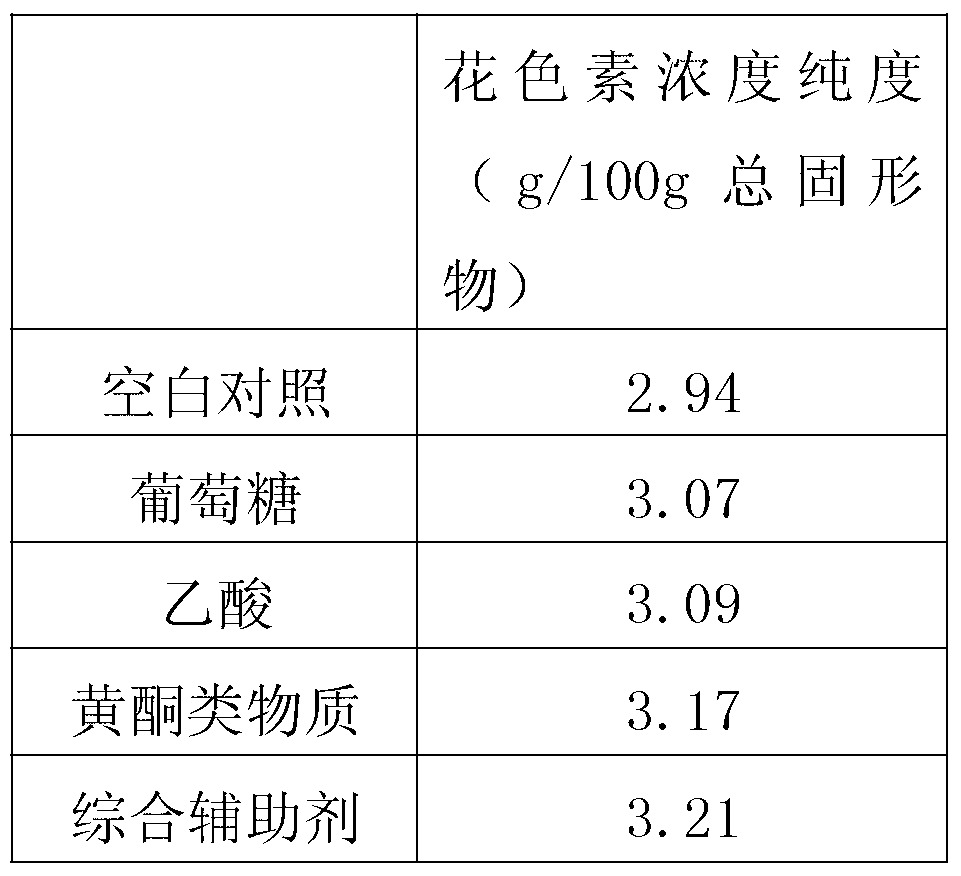

[0036] 5) Ultrasonic extraction: add 1% glucose, 1% acetic acid, and 2% natural flavonoids such...

Embodiment 2

[0042] The present invention separates the method for anthocyanin from purple highland barley, comprises the following steps:

[0043] 1) Select clean purple highland barley without deterioration and mildew, and use peeling machine peeling technology to collect the outer skin part of purple highland barley;

[0044] 2) Crush the purple highland barley bark, and carry out micro-grinding treatment, so that the particle size is between 0.2mm;

[0045] 3) Add water 1.5 times the weight of the purple barley barley barley barley barley, then add citric acid to adjust the pH3, soak at 30°C for 1 hour;

[0046] 4) Add 90% ethanol solution to the soaked purple highland barley bark at a mass ratio of 1:1 to extract twice, each time for 3 hours, filter, combine the filtrate, and then place it at room temperature for 3 hours at 20°C to obtain the extract;

[0047] 5) Ultrasonic extraction: Add 2% glucose, 0.5% acetic acid, and 3% natural flavonoids such as phlorizin to the extract, then ...

Embodiment 3

[0053] The present invention separates the method for anthocyanin from purple highland barley, comprises the following steps:

[0054] 1) Select clean purple highland barley without deterioration and mildew, and use peeling machine peeling technology to collect the outer skin part of purple highland barley;

[0055] 2) Crush the purple highland barley bark, and carry out micro-grinding treatment, so that the particle size is between 0.2mm;

[0056] 3) Add water 1.5 times the weight of the purple barley barley to the purple barley barley, then add citric acid to adjust the pH3, soak at 25°C for 2 hours;

[0057] 4) Add 80% ethanol solution to the soaked purple highland barley bark at a mass ratio of 1:1 to extract twice, each time for 3 hours, filter, combine the filtrate, and then place it at room temperature for 2 hours at 25°C to obtain the extract;

[0058] 5) Ultrasonic extraction: Add 1.5% glucose, 0.8% acetic acid, and 2.5% natural flavonoids such as naringin to the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com