Bacteriostatic PVC film

A technology of PVC film and PVC resin powder, which is applied in the field of antibacterial PVC film, can solve the problems of excessive photocatalytic performance affecting health, lack of antibacterial function, and large damage to human body, so as to inhibit the growth of bacteria and avoid health problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A bacteriostatic PVC film, comprising the following raw materials in parts by weight: 100 parts of PVC resin powder, 0.1 part of Angelica dahurica essential oil, 22 parts of acetyl tri-n-butyl citrate, 2 parts of mercaptan methyl tin stabilizer, hard Zinc fatty acid 0.5 part.

Embodiment 2

[0016] A bacteriostatic PVC film, comprising the following raw materials in parts by weight: 120 parts of PVC resin powder, 0.5 part of Angelica dahurica essential oil, 28 parts of acetyl tri-n-butyl citrate, 5 parts of mercaptan methyl tin stabilizer, hard Zinc fatty acid 1 part.

Embodiment 3

[0018] A bacteriostatic PVC film, comprising the following raw materials in parts by weight: 110 parts of PVC resin powder, 0.3 parts of Angelica dahurica essential oil, 25 parts of acetyl tri-n-butyl citrate, 4 parts of mercaptan methyl tin stabilizer, hard Zinc fatty acid 0.8 part.

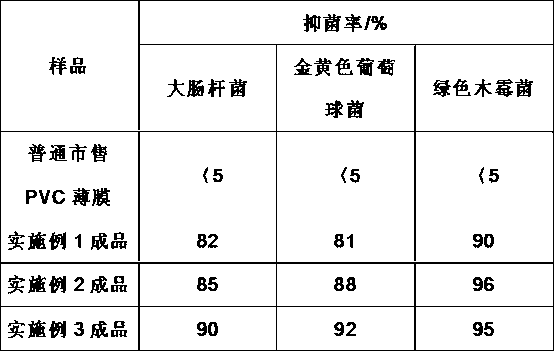

[0019] Detection and analysis of antibacterial performance of this product:

[0020] Place 100 films of the present invention whose specifications are 0.5cm×1cm in the bacterium liquid of mucormycetes, and after shaking and cultivating at room temperature for 3 hours, take 2 drops of the culture solution to measure the number of spore germination with a microscope, and calculate the spore germination rate; under the same conditions, With common PVC film as contrast, obtain the bacteriostasis effect of embodiment 1~3, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com