Tube-shell type solid-solid heat exchanger

A heat exchanger, shell-and-tube technology, which is applied in the field of shell-and-tube solid-solid heat exchangers, can solve the problems that no feasible method has been found, the limitation of solvent-oil ratio, etc., and achieve the goal of increasing the liquid yield of the device and increasing the solvent-oil ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

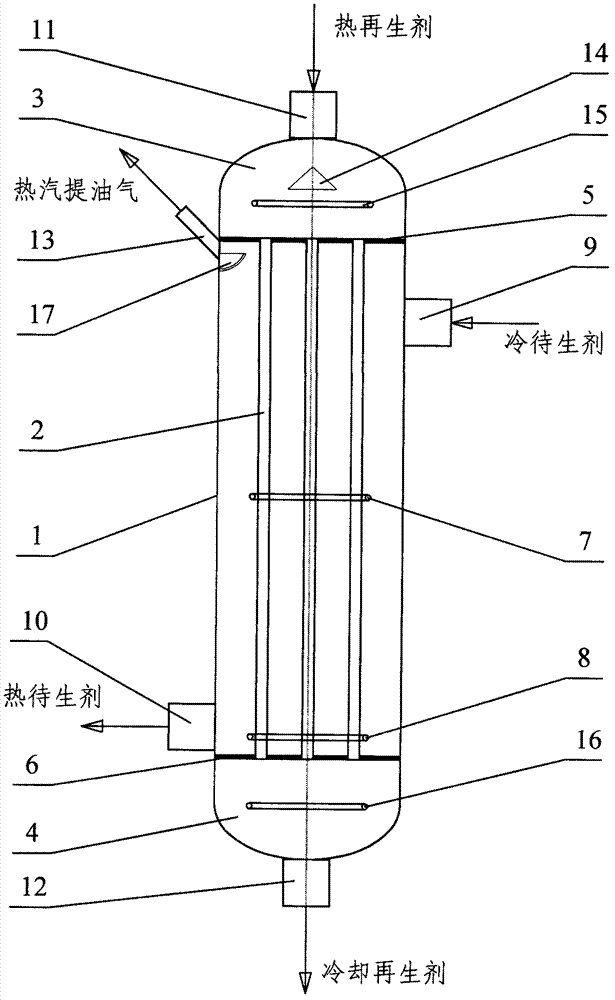

[0027] figure 1 It shows a shell-and-tube solid-solid heat exchanger, which consists of a shell (1), a heat exchange tube (2), an upper head (3), a lower head (4), an upper tube sheet (5), a lower tube sheet (6), fluidization air distributor in the middle of the shell side (7), fluidization air distributor in the lower part of the shell side (8), inlet of cold standby agent (9), outlet of hot standby agent (10), inlet of hot regeneration agent (11), cooling regeneration agent outlet (12), hot stripping oil gas outlet (13), catalyst distribution plate in the upper part of the tube pass (14), fluidization air distributor in the upper part of the tube pass (15), fluidization air distribution in the lower part of the tube pass device (16), arc-shaped baffle (17); the shell side is composed of the shell (1), heat exchange tube (2), upper tube sheet (5), and lower tube sheet (6). The head (3), the lower head (4) and the internal flow space of the heat exchange tube (2) form the tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com