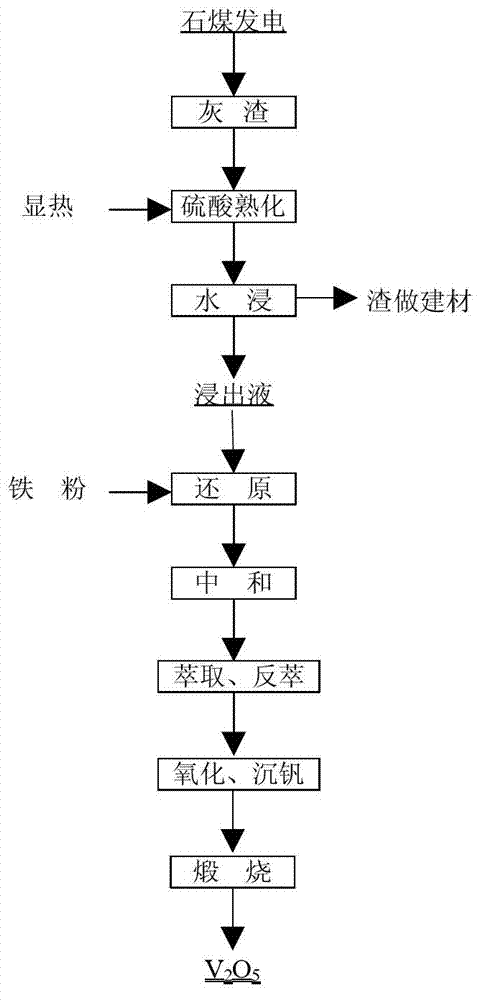

Method for extracting vanadium by using vanadium-containing stone coal power generation ash with sensible heat and low energy consumption

A low energy consumption, vanadium ore technology, applied in the field of nonferrous metallurgy, can solve the problems of energy waste, slag sensible heat waste, direct utilization without mentioning, etc., and achieve the effect of reducing energy consumption and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Place 100 kg of overflow slag with a temperature above 200°C and a particle size of about 60 mesh and a temperature of about 800°C and a particle size below 8 mm in a closed reaction vessel at a ratio of about 30:100, and add 30 kg of concentrated sulfuric acid. Soak and ripen for 2 hours, then add water and stir for leaching. The leaching residue was filtered, washed, dried, and sent for sample analysis. The leaching rate of vanadium pentoxide in the slag was 43.7%.

Embodiment 2

[0037]Place 100 kg of overflow slag with a temperature above 200°C and a particle size of about 60 mesh and a temperature of about 800°C and a particle size below 8 mm in a closed reaction vessel at a ratio of about 50:100, and add 50 kg of concentrated sulfuric acid. Soak and ripen for 3 hours, then add water and stir for leaching. The leaching residue was filtered, washed, dried, and sent for sample analysis. The leaching rate of vanadium pentoxide based on the slag was 60.7%.

Embodiment 3

[0039] Place 100 kg of overflow slag with a temperature above 200°C and a particle size of about 60 mesh and a temperature of about 800°C and a particle size below 8 mm in a closed reaction vessel at a ratio of about 50:100, and add 50 kg of concentrated sulfuric acid. Soak and ripen for 10 hours, then spray water for leaching. The leaching residue was filtered, washed, dried, and sent for sample analysis. The leaching rate of vanadium pentoxide in the slag was 70.7%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com