The method of controlling the thickness of the protective layer on the surface of the steel mesh of the floor slab and the mold used

A technology of protective layer thickness and steel mesh, which is applied in the field of building slab pouring, can solve problems such as stirrup tilt, processing error, and uneven upper steel mesh, so as to reduce pouring errors, reduce pouring costs, and improve construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

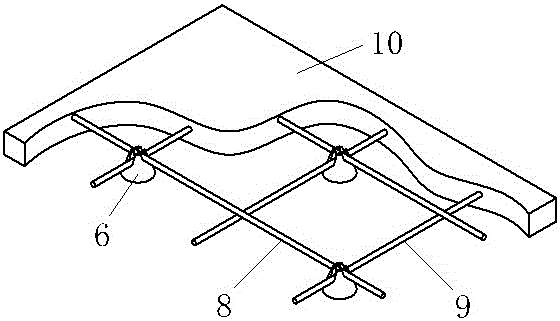

[0024] The thickness B of the slab in this example is 100±5mm, and the diameter D of the reinforcing steel mesh of the upper layer is 10mm. Concretely implement the construction according to the following steps:

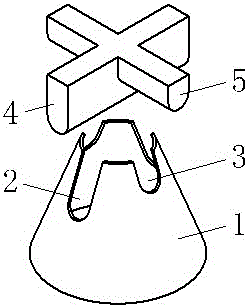

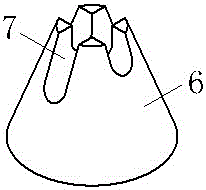

[0025] 1. Make the shaped concrete mold first. The shaped concrete mold comprises a conical cylinder 1 and a cross die made of 2mm steel plates. The upper hole diameter of the cone 1 is 50mm, the lower hole diameter is 120mm, and the height of the cone 1 is 95mm. The upper opening of the conical cylinder 1 is provided with four notches evenly distributed along the circumference, and the bottom of the notches is an arc. One pair of opposite notches is the deep notch 2, and the other pair of opposite notches is the shallow notch 3. The deep notch 2 has a depth equal to 25 and the shallow notch 3 has a depth equal to 15. The cross die includes vertically intersecting deep groove bead 4 and shallow groove bead 5 . The length of deep groove bead 4 and shallow groove ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com