Three-column steel pipe tower

A technology of steel pipe tower and main pipe, applied in the field of transmission tower, can solve the problems of low utilization rate of materials, difficult processing, large diameter of main pipe, etc., and achieve the effect of beautiful appearance, good stability and clear force transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

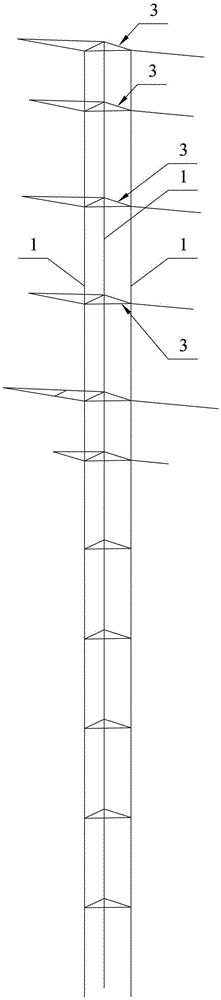

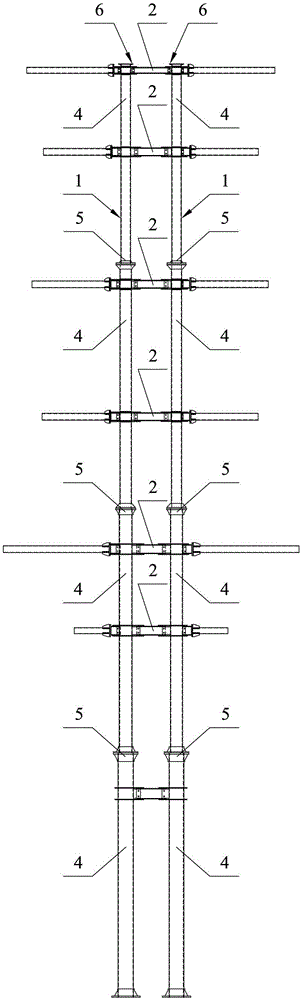

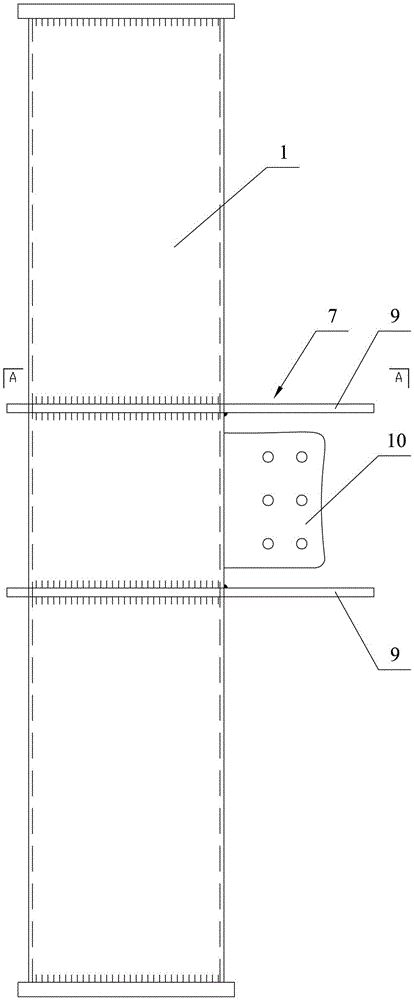

[0030] Embodiment one: see attached figure 1 shown. A three-column steel pipe with four towers is used in power transmission and transformation lines. The three-column steel pipe 4 tower includes three vertically arranged main pipes 1 arranged in a triangle, and a multi-layer triangular transverse partition 3 composed of three horizontal pipes 2 connecting the three main pipes 1 . Two main pipes 1 are set on the pressure side of the three-column steel pipe 4 tower, the other main pipe 1 is set on the tension side of the three-column steel pipe 4 tower, and the pipe of the main pipe 1 set on the tension side of the three-column steel pipe 4 tower The diameter is greater than the pipe diameter of the main pipe 1 arranged on the pressure side of the three-column steel pipe 4 tower.

[0031] The three-column steel pipe 4 tower is similar to the multi-layer rigid frame structure system, and the overall force is better. The overall bending moment at the root of the steel pipe 4 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com