Mobile car automatic weighing platform

A weighing platform and mobile technology, applied in the field of automatic loading and weighing devices for mobile vehicles, can solve the problems of difficult production, large installation space, poor accuracy, etc., achieve convenient and fast installation and disassembly, reduce use failures, and facilitate production and production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

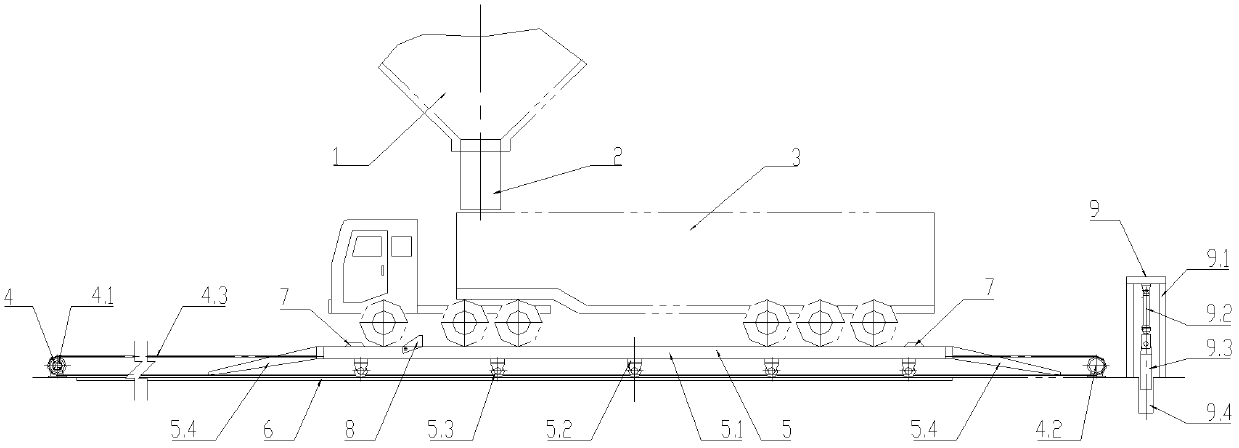

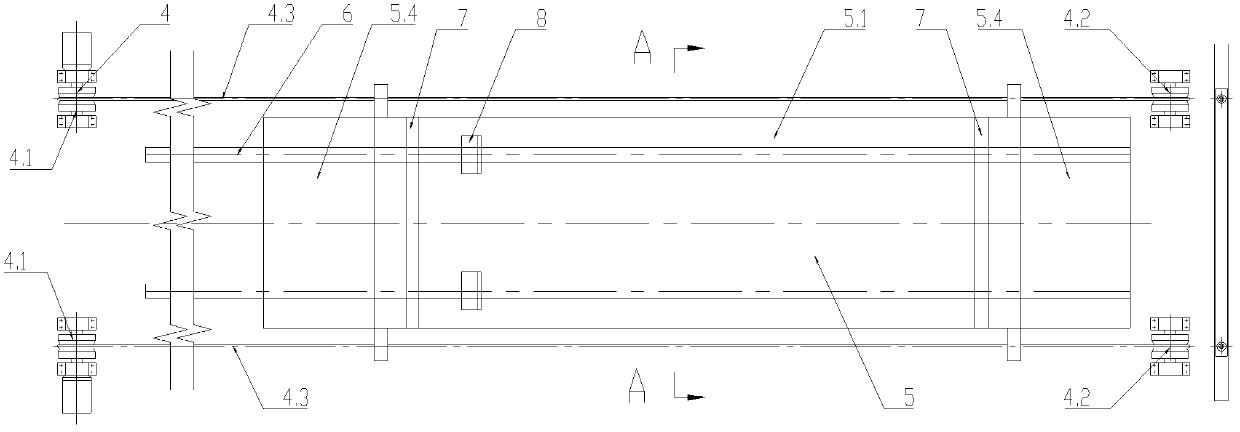

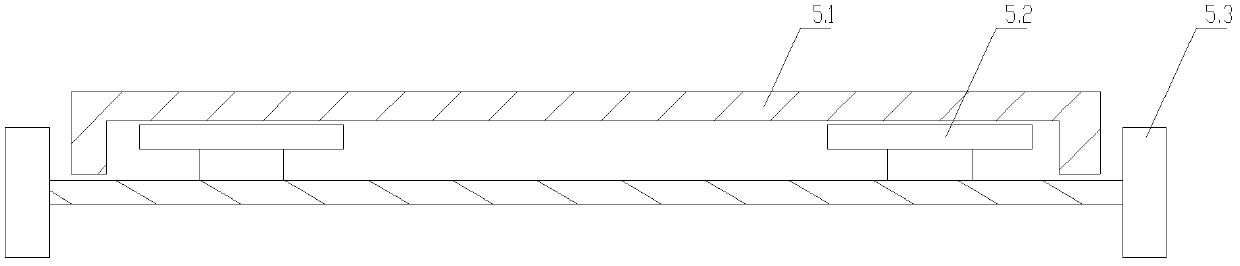

[0056] Figure 1 to Figure 5It is the mobile vehicle automatic loading and weighing device described in this embodiment, which is installed below the discharge port 2 of the feed bin 1 . Including a weighing platform 5 arranged on the foundation, the weighing platform 5 includes a weighing platform 5.1, a traveling mechanism, and a weighing sensor 5.2, the weighing platform 5.1 is arranged on the traveling mechanism, and the weighing sensor 5.2 is arranged on the weighing platform The lower part of the plate 5.1, the traveling mechanism drives the weighing platform 5.1 and the load cell 5.2 to travel. In this embodiment, the traveling mechanism is a rope and rope reel mechanism. The traveling mechanism includes a roller 5.3, a guide rail 6 and a tractor. The sensor 5.2 is connected; on the basis, a guide rail 6 matched with the roller 5.3 is set, and the roller 5.3 runs along the guide rail 6 to reduce resistance and prevent deviation. In this embodiment, the tractor is a wi...

Embodiment 2

[0066] Figure 6 to Figure 8 It is the mobile vehicle automatic loading weighing device described in this embodiment. The difference from Embodiment 1 is that the tractor is a rack-and-pinion tractor 10, and the rack-and-pinion tractor 10 includes a drive mechanism 10.1, and the drive mechanism 10.1 is arranged on the foundation, and the drive mechanism 10.1 includes a gear 10.1.1, which moves The weighing table 5 is provided with a rack 10.2 matched with the gear 10.1.1, the gear 10.1.1 meshes with the rack 10.2, and the driving mechanism 10.1 moves the mobile weighing table 5 through the meshing transmission of the rack and pinion. The mobile weighing platform 5 is provided with a fixed vehicle stopper 7, and the fixed vehicle stopper 7 positions the automobile 3 on the mobile weighing platform 5. The car stopper adopts a stop bar type car stop 11, and the stop bar type car stop 11 includes a support 11.1, a hydraulic cylinder 11.2 and a stop bar 11.3, and one end of the hy...

Embodiment 3

[0070] Figure 9 to Figure 11 It is the mobile vehicle automatic loading weighing device described in this embodiment. The difference from Embodiment 1 is that the tractor is a pintooth tractor 12, and the pintooth tractor 12 includes a driving mechanism 12.1. The driving mechanism 12.1 is arranged on the foundation, and the driving mechanism 12.1 includes a pin gear 12.1.1. The platform 5 is provided with a pin rack 12.2 matched with the pin gear 12.1.1, and the driving mechanism 12.1 moves the mobile weighing platform 5 through the engagement transmission between the pin gear 12.1.1 and the pin rack 12.2.

[0071] The mobile weighing platform 5 is provided with a movable vehicle stopper 8, and the movable vehicle stopper 8 locates the automobile 3 on the mobile weighing platform 5.

[0072] The car stopper adopts a curtain-type car stopper 13, and the curtain-type car stopper 13 includes a support 13.1, a rope reel 13.2 and a curtain 13.3, and a support 13.1 is respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com