Lighting system and method used for dark field detection of defect in spherical optical element surface

A technology of optical components and spherical optics, applied in the direction of optical components, optical testing flaws/defects, optics, etc., can solve the problems of poor repeatability, incapable of quantitative detection, and inability to perform follow-up detection, etc., to achieve good contrast and easy subsequent image processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0043] This embodiment is an illumination system that can be used for dark field detection of surface defects of spherical optical elements.

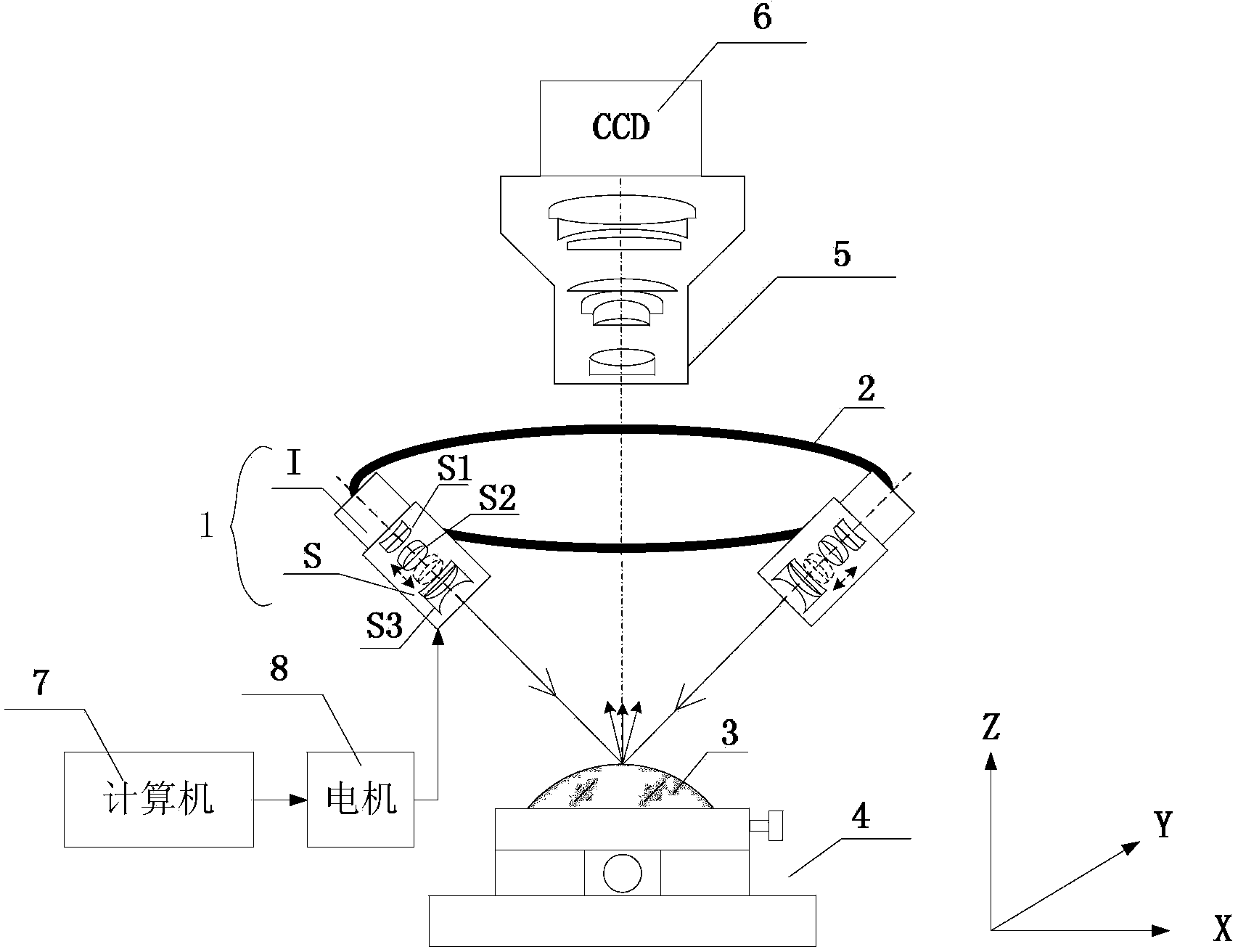

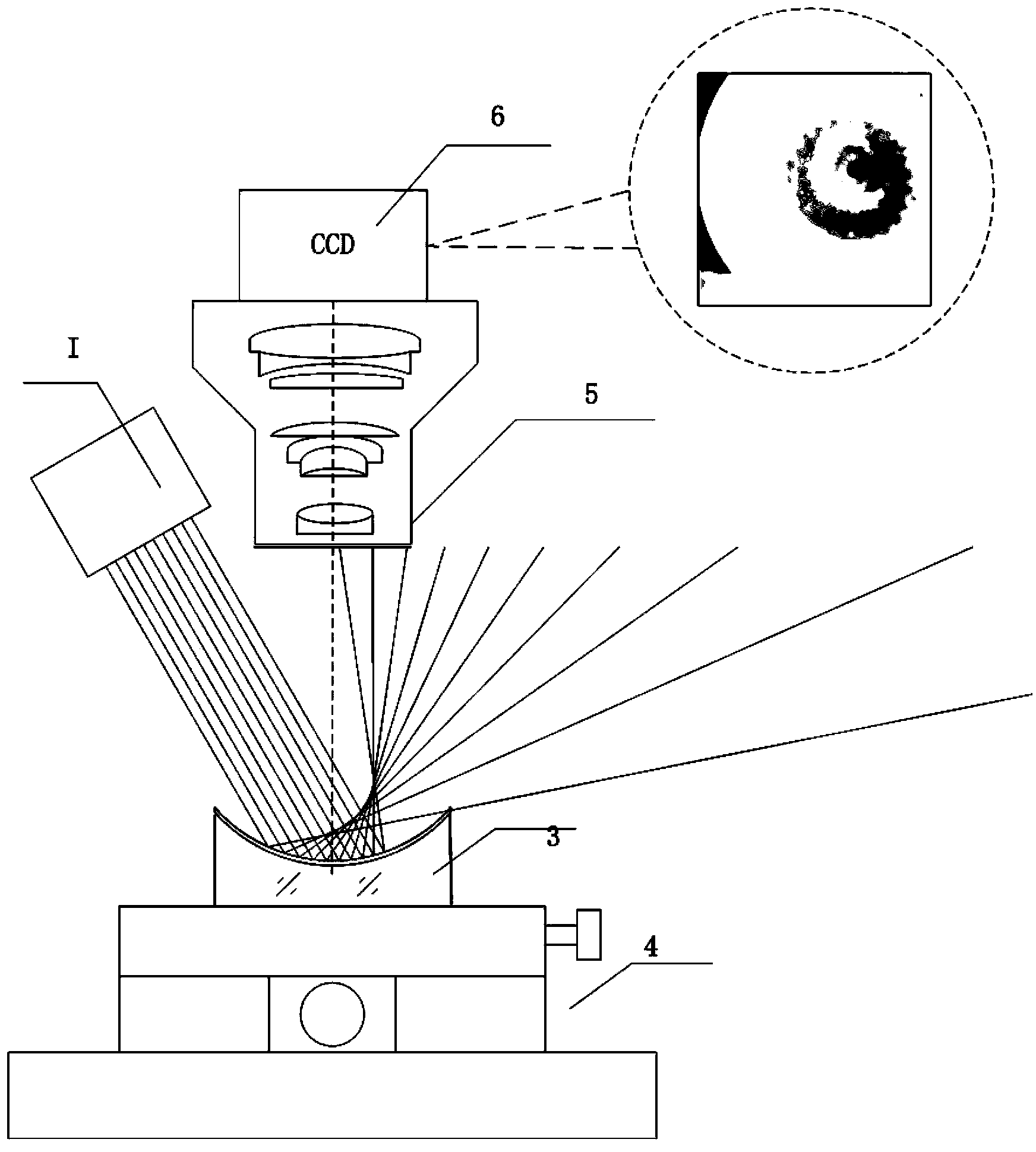

[0044] lighting system such as figure 1 As shown, it includes a spherical light source 1 , a light source bracket 2 , an optical element to be tested 3 , a clamping device 4 , a microscopic imaging system 5 , a charge-coupled device CCD 6 , a computer 7 , and a motor 8 .

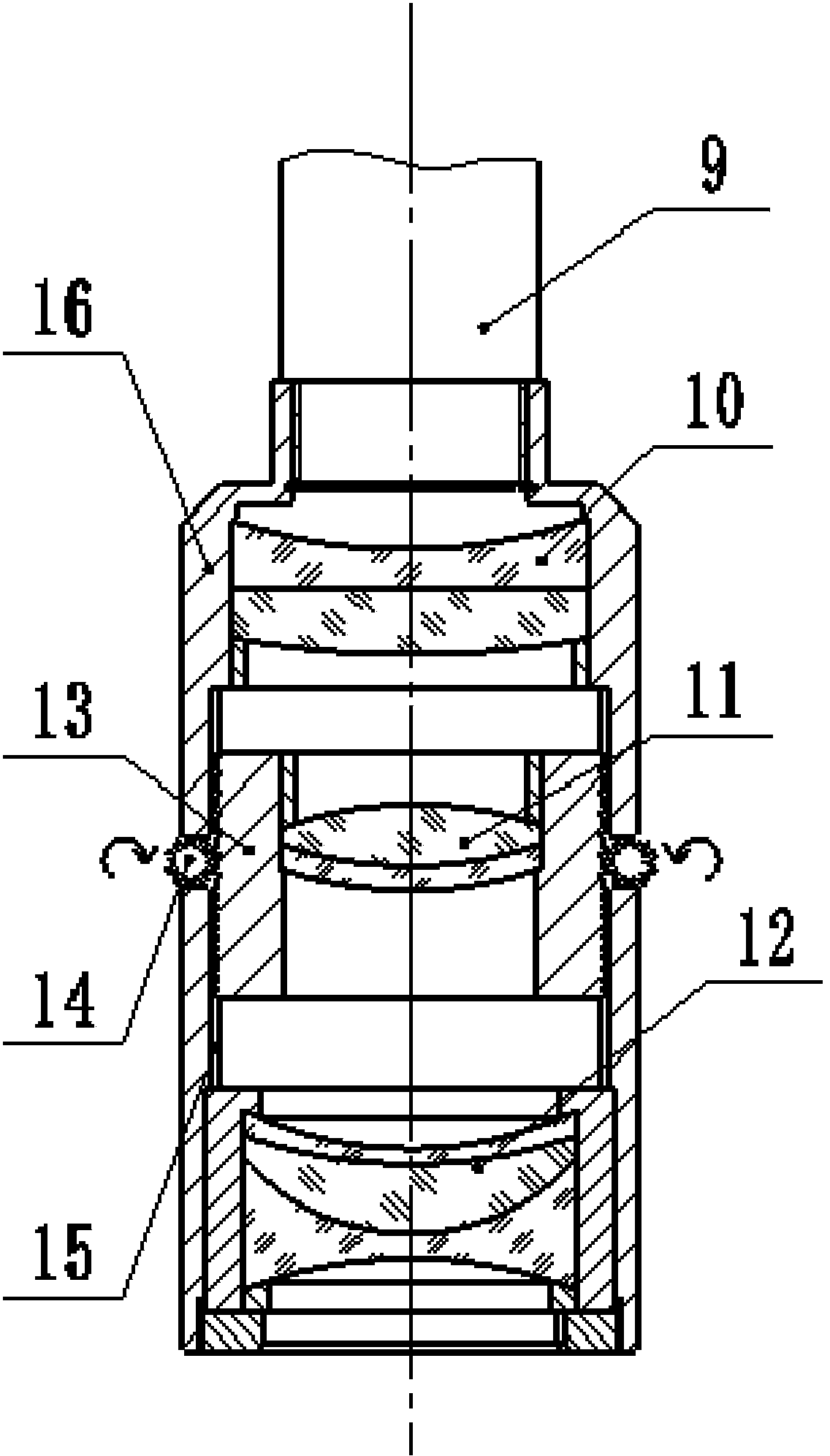

[0045] The spherical light source 1 is composed of a uniform surface light source and a lens barrel of a zoom lens group, and a plurality of light sources 1 are mounted on the light source bracket 2 at equal intervals in a ring. The mechanical structure of the zoom adjustment assembly S is as follows: figure 2 As shown, the zoom adjustment assembly S is composed of a zoom lens group lens barrel 16, a front fixed lens group 10, a zoom lens group 11, a rear fixed lens group 12, a zoom lens barrel 13, a gear 14, and a slide rail 15. Front fixed mirror group 10, zoom m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com