Manufacturing method for metamaterial board, metamaterial antenna housing and manufacturing method for metamaterial antenna housing

A manufacturing method and metamaterial technology, applied in the field of metamaterials, can solve problems such as complex processing processes, and achieve the effect of simple process, superior mechanical properties, and not easy to wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

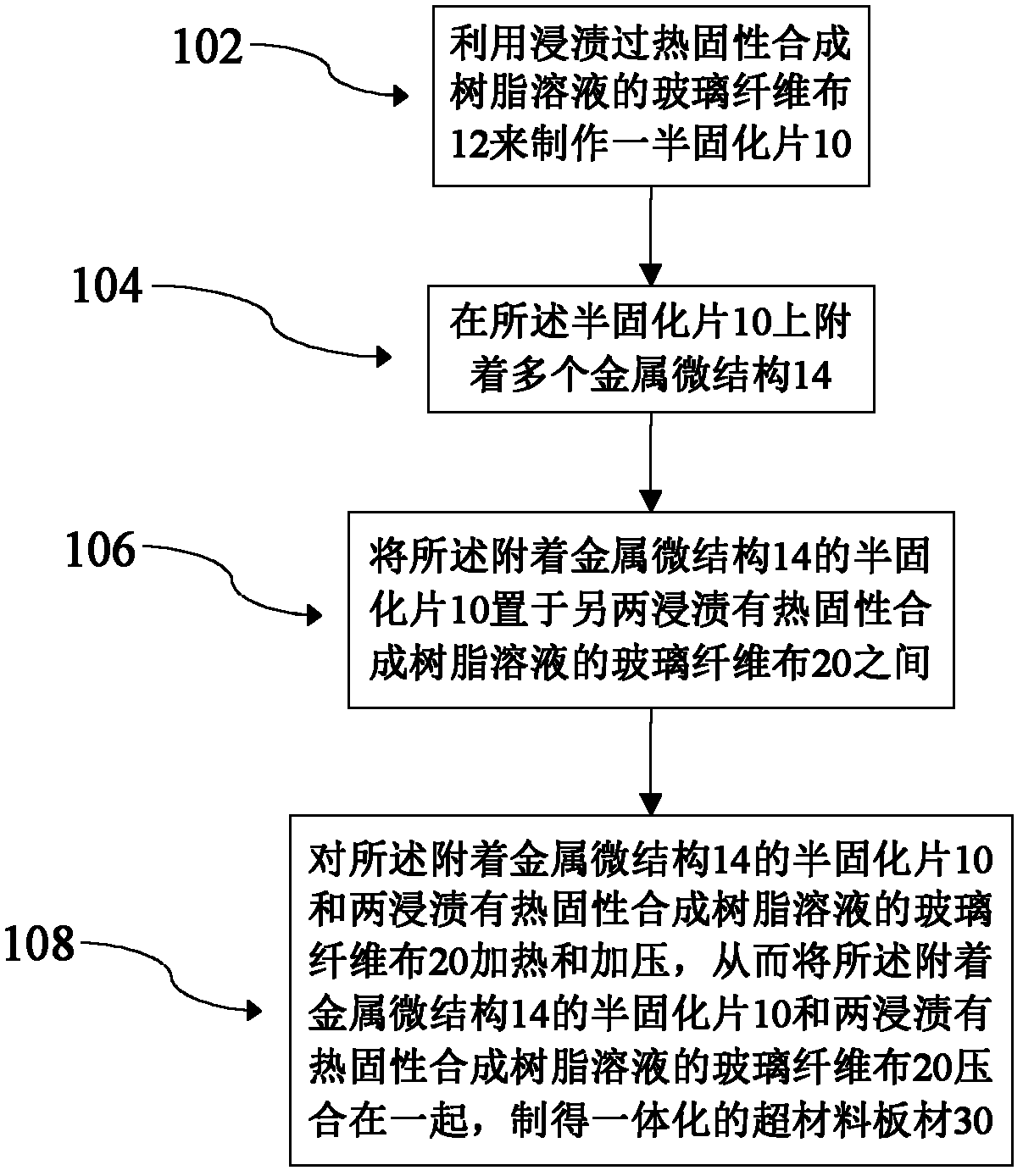

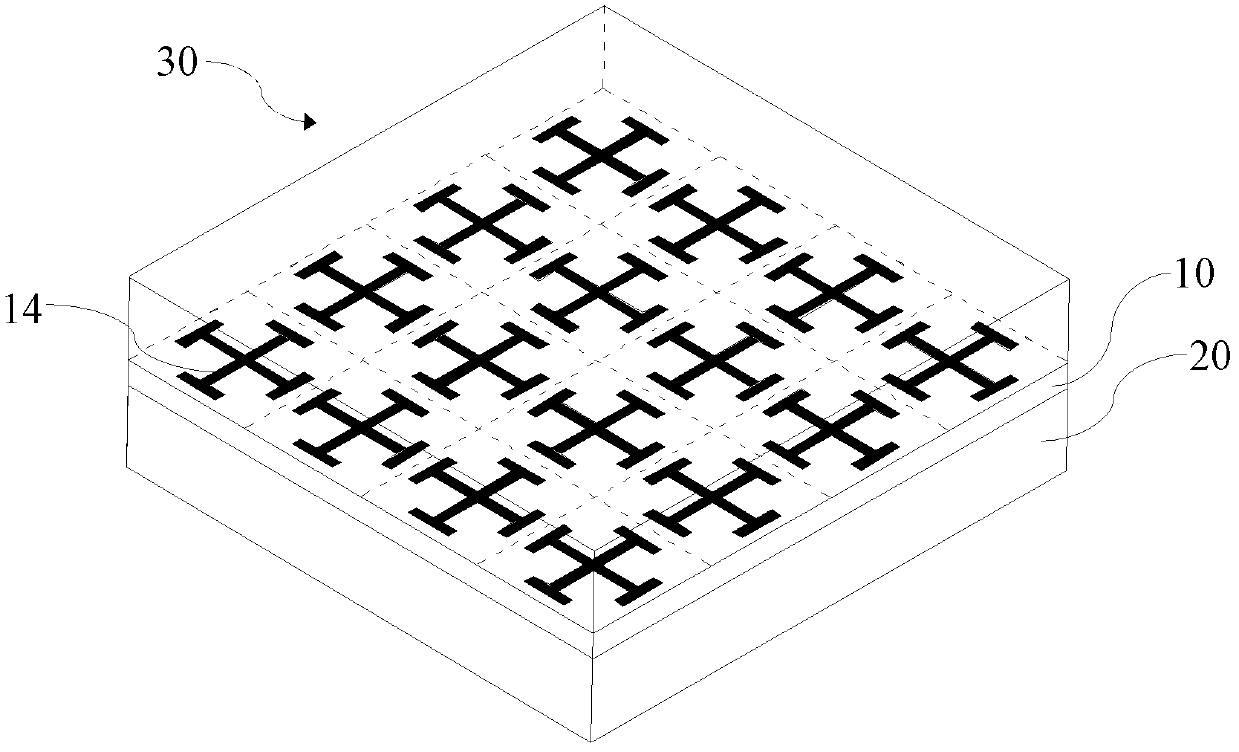

[0044] Such as Figure 1 to Figure 3 Shown is an embodiment of the manufacturing method of the metamaterial sheet of the present invention and an example of the supermaterial sheet made therefrom, the embodiment includes the following steps:

[0045] Step 102: Making the prepreg 10 by using the glass fiber cloth 12 impregnated with the thermosetting synthetic resin solution.

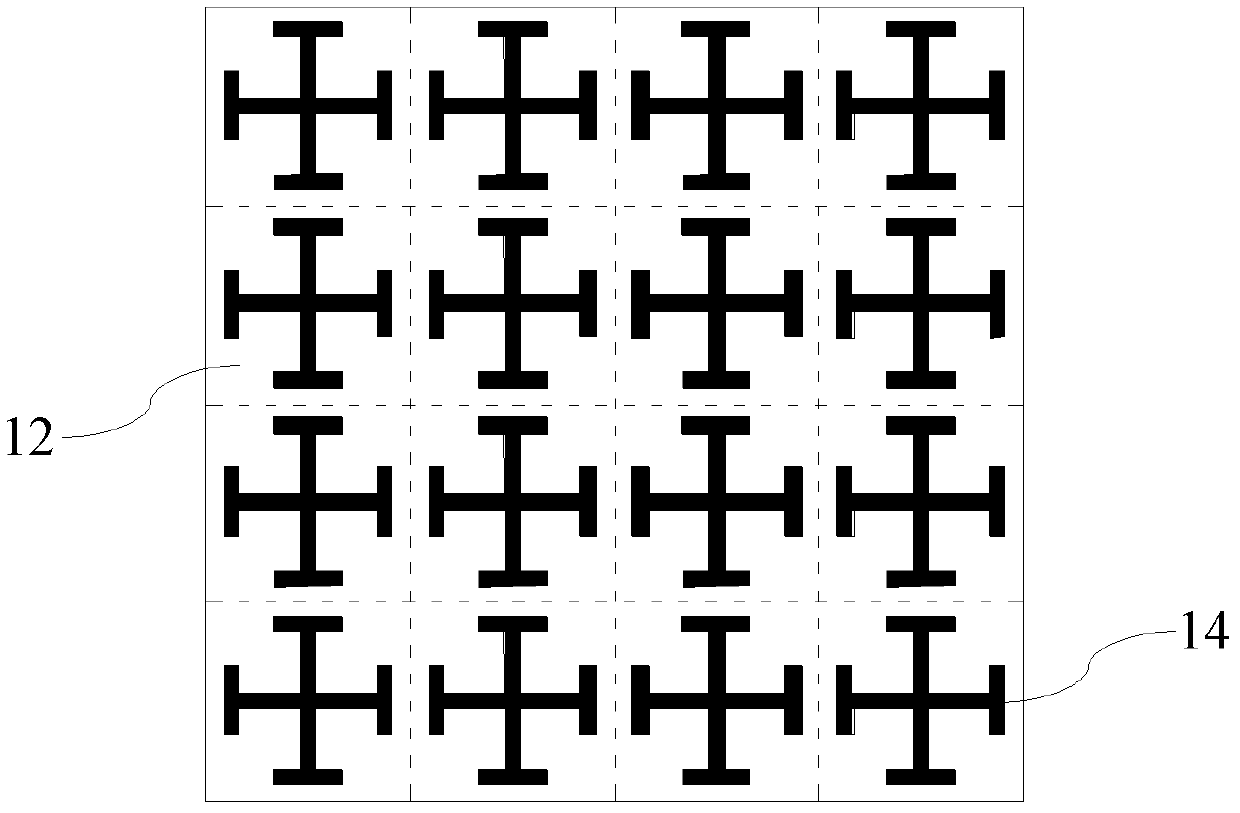

[0046] Step 104 : attaching a plurality of metal microstructures 14 on the prepreg 10 . figure 2 and image 3 Shown in is only an example of the metal microstructure 14, in fact, the geometric size and shape of the metal microstructure 14 can be changed arbitrarily according to the electromagnetic response to be achieved, and the arrangement of the plurality of metal microstructures 14 The way of cloth can also be changed arbitrarily.

[0047] Step 106: Place the prepreg 10 attached with the metal microstructure 14 between two other glass fiber cloths 20 impregnated with a thermosetting synthetic res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com