Driver of brushless electric machine and circuit thereof

A brushless motor and driver technology, applied in the direction of starting devices, etc., can solve the problems of excessive current in the controller or circuit, burnt circuit components, burned components, etc., to reduce the risk of burning, motor startup safety, and improve safety performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

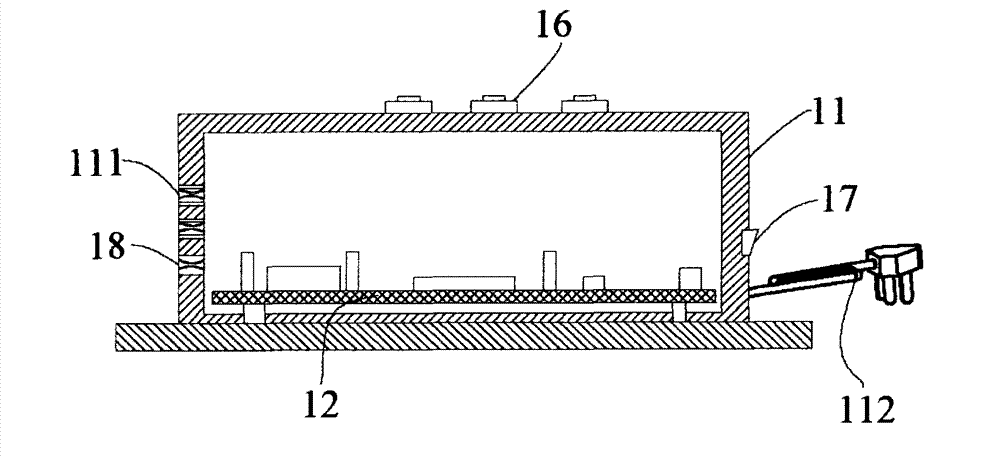

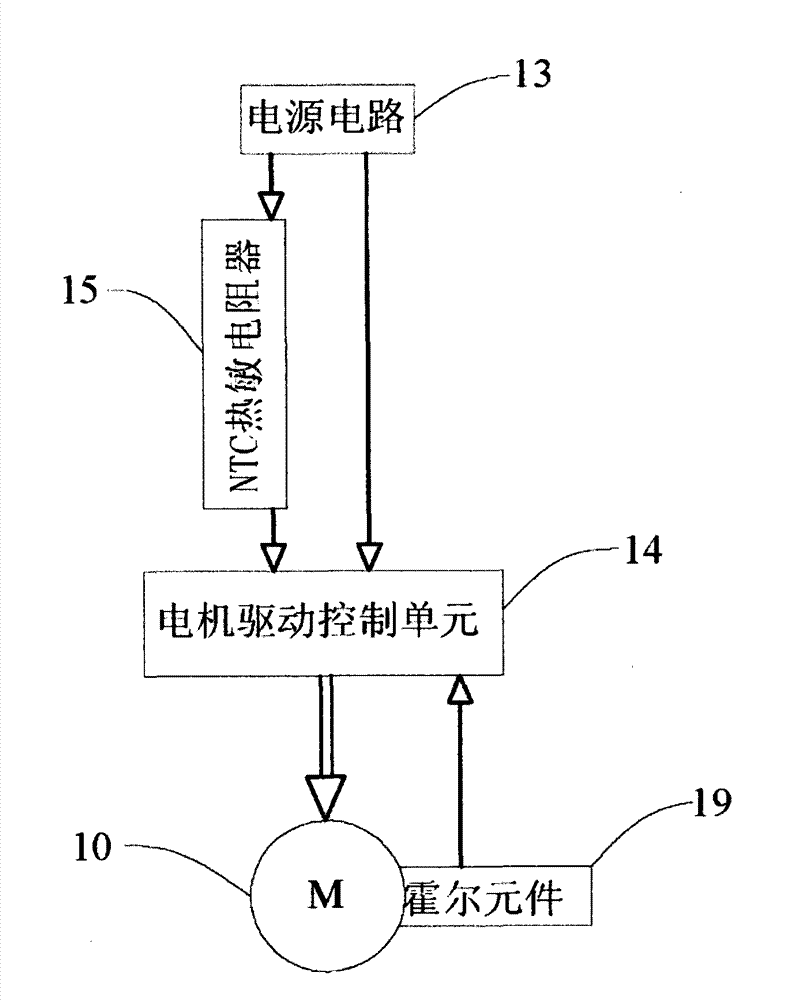

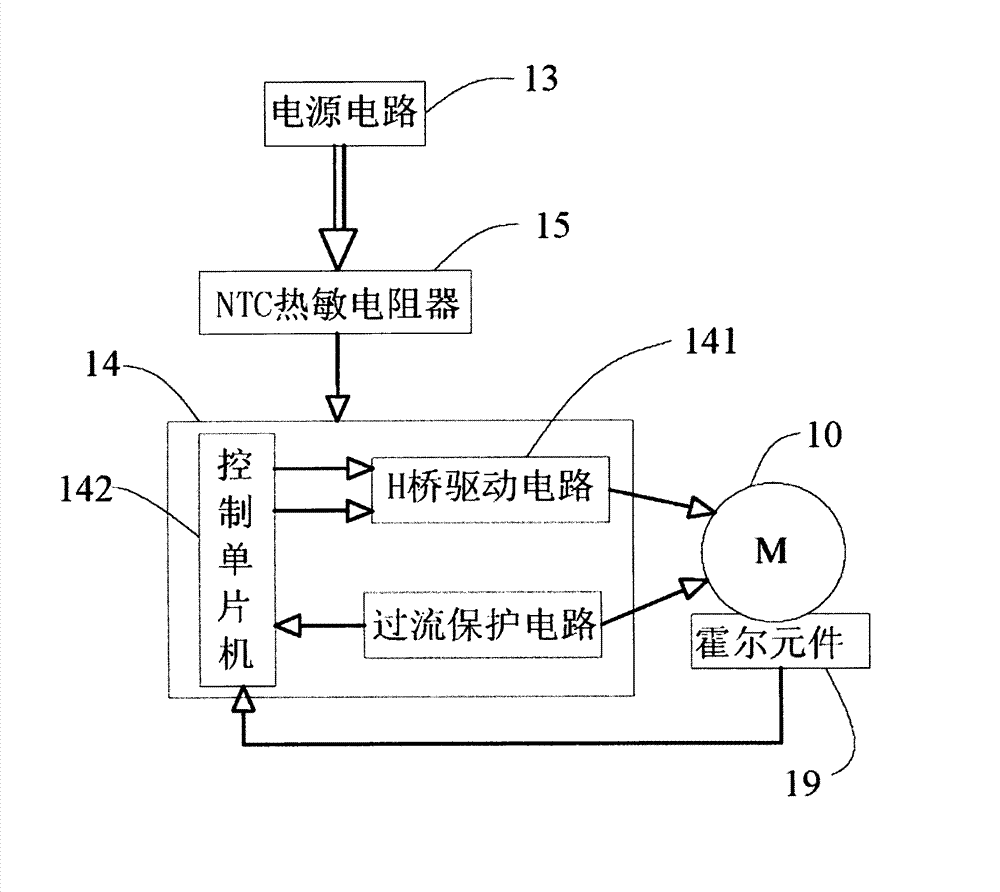

[0023] See figure 1 , figure 2 with image 3 The illustrated embodiment of the driver of the brushless motor 10 of the present invention includes a housing 11, a control circuit board 12 is built in the housing 11, a control output interface 111 and a power connection line 112 are provided on the housing, and the control circuit board 12 includes The power supply circuit 13 and the motor start control unit 14 include a drive circuit 141 and a control single-chip 142. The control circuit board 12 also includes a power NTC thermistor 15 with a negative temperature coefficient, and the power NTC thermistor 15 is connected in series between the power circuit 13 and the motor start control unit 14.

[0024] The housing 11 is also provided with a motor speed adjustment button 16 and a power switch 17. The motor speed control button 16 is connected to the control circuit board 12. The power switch 17 connects the power cord and the control circuit board 12.

[0025] The power supply c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com