Medical six-degree-of-freedom automatic adjusting manipulator grinding and clamping device for surgical operation

An automatic adjustment and clamping device technology, applied in the field of medical equipment, can solve the problems of reducing operation efficiency, increasing operation difficulty, and patient injury, achieving high control accuracy and avoiding mechanical damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

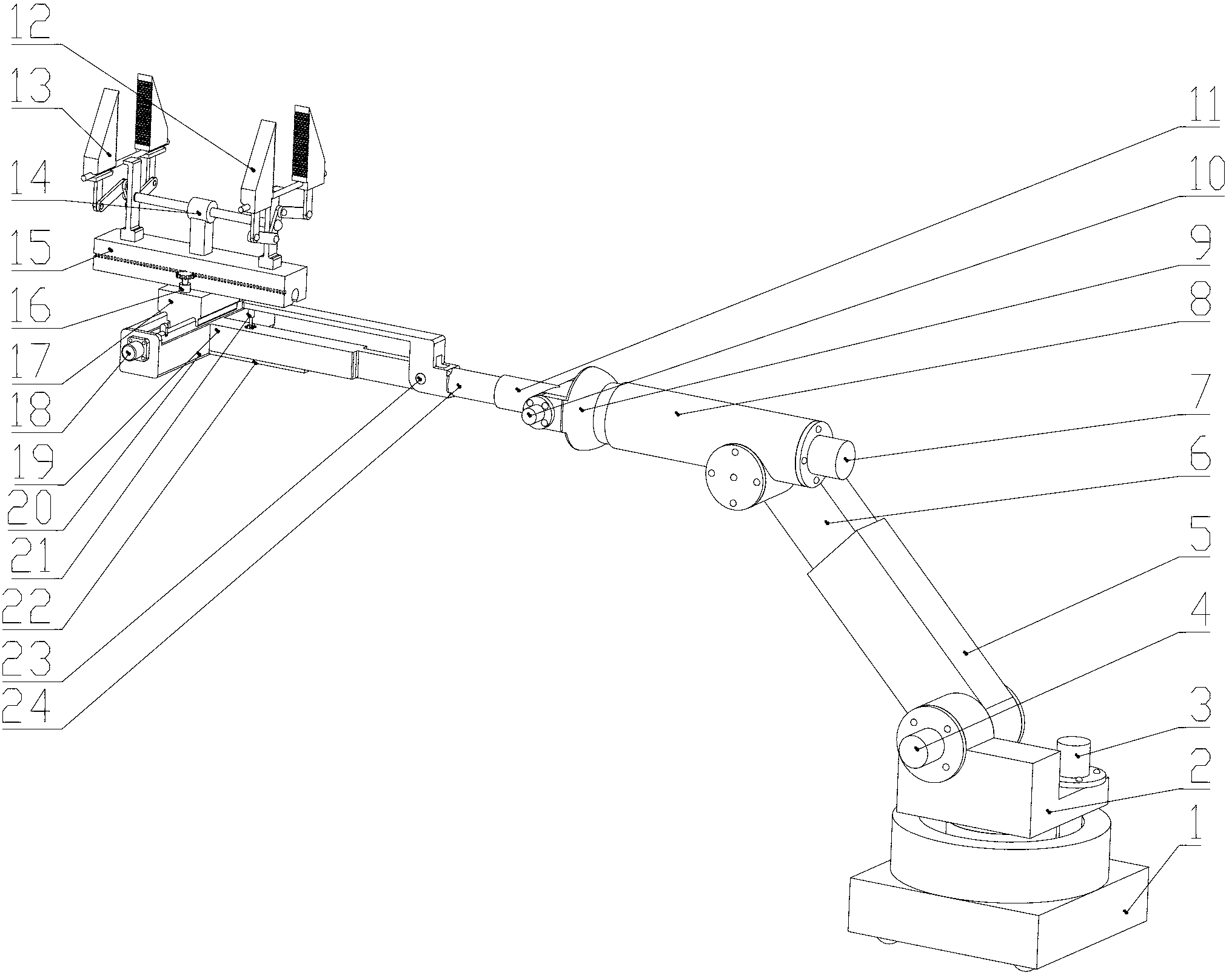

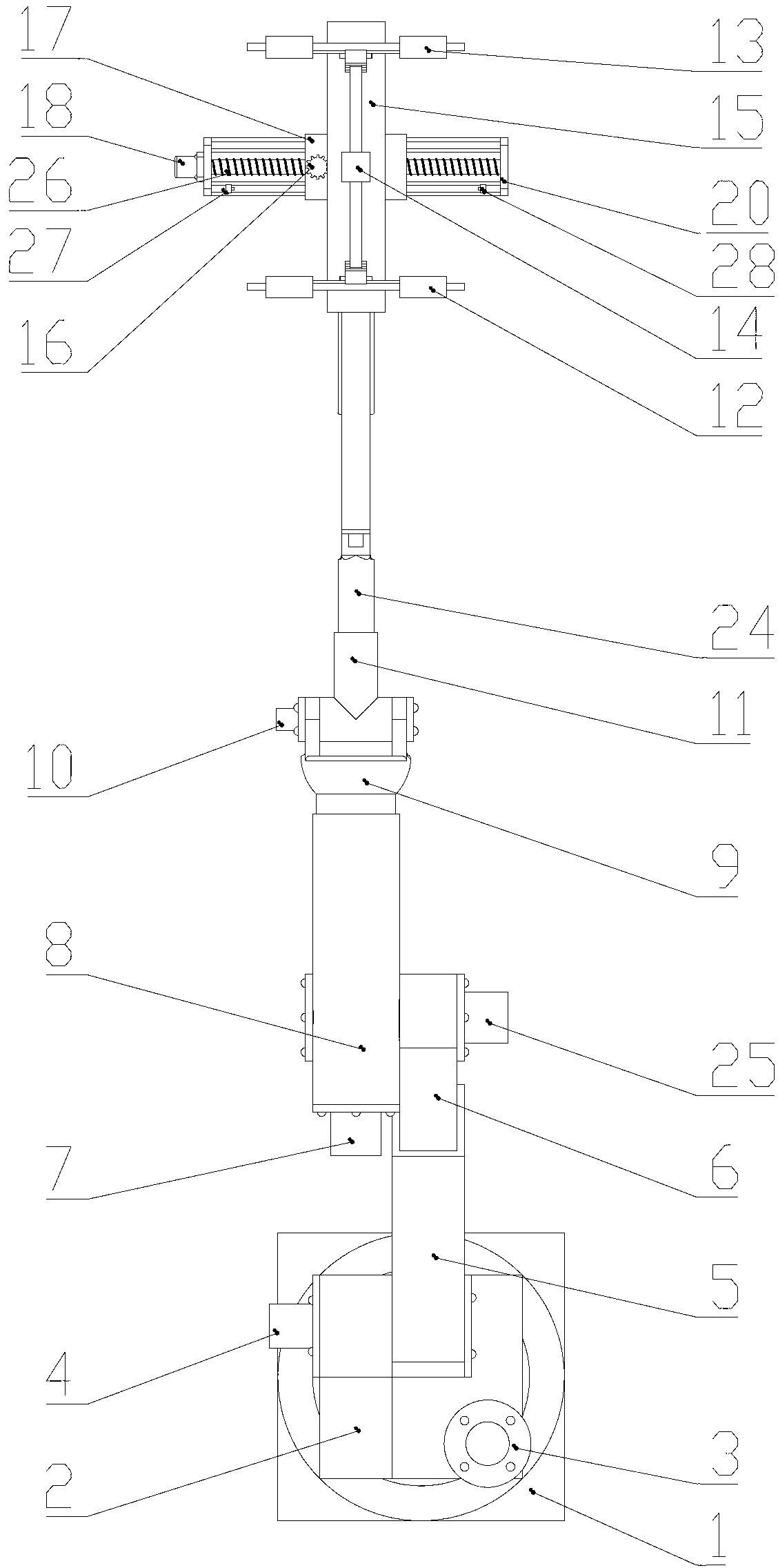

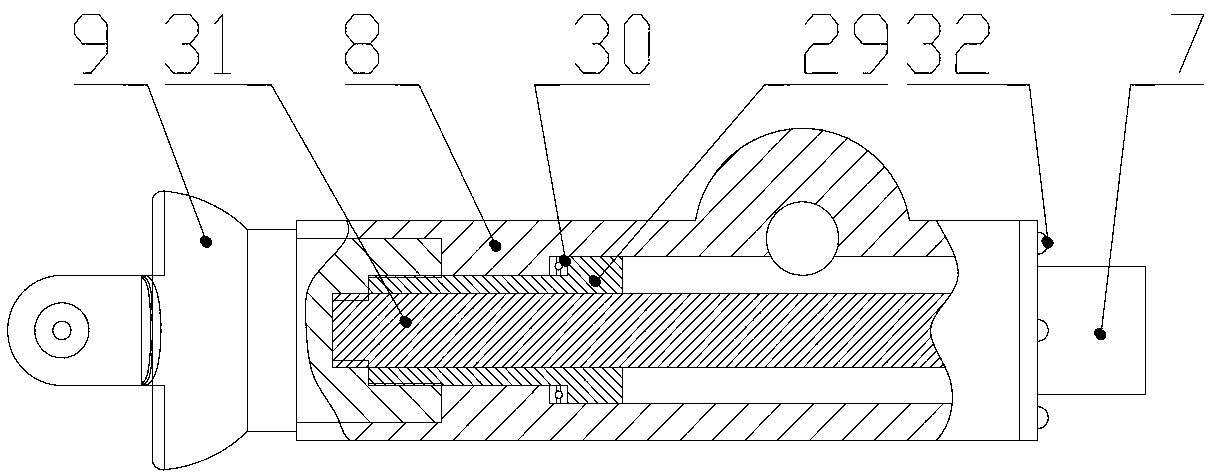

[0037] figure 1 It shows the various components of the six-degree-of-freedom automatic adjustment robotic arm grinding and clamping device for medical surgery, combined with figure 1 , figure 2 , the transmission and positioning of its various parts are as follows: the base 1 is a solid metal material, which plays a role in maintaining the center of gravity of the device in the whole device, so that the device is not easy to fall due to force or other parts being too heavy. There is a hole in the center of the upper part of the base 1. Insert the shaft at the lower end of the turntable 2 into the center hole of the base 1. There is an annular groove outside the center hole. The large-diameter inner surface of the annular groove is designed as an internal gear. The main shaft of the motor I3 Designed as a gear shaft, the motor I3 passes through the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com