Preparation method of machine-made sand capable of replacing natural sand

A technology of manufactured sand and natural sand, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

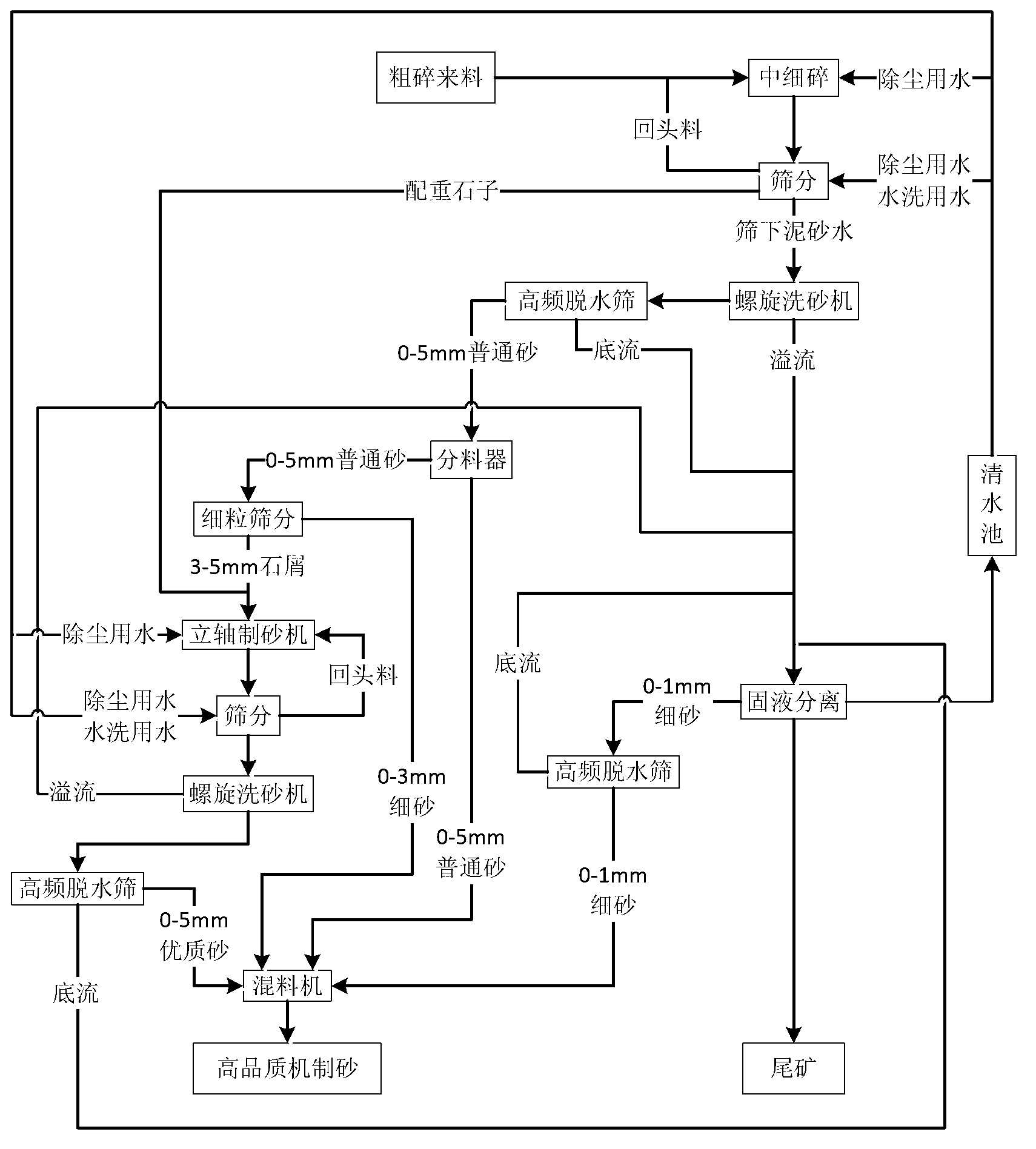

[0057] This example is based on the quality standard of GB / T 14684 "Sand for Construction", and mainly controls the gradation, mud content, stone powder content, and fineness modulus index. The preparation process can be combined with the attached figure 1 come to understand.

[0058] (1) Preparation process of machine-made sand products

[0059] ①Using andesite as raw material, it is subjected to coarse crushing by gyratory crusher, intermediate crushing by cone crusher and fine crushing by cone crusher to obtain crushed stone. Vibrating sieve sieving, vibrating sieve water washing, spiral sand washing machine fishing, high-frequency sieve dehydration to obtain 0 ~ 5mm ordinary sand, the graded waste water containing fine sand is subjected to solid-liquid separation process, that is, hydrocyclone centrifugal separation After dehydration with high-frequency sieve, 0-1mm fine sand (part) is obtained.

[0060] ② Take part of the 0-5mm ordinary sand through the feeder, and siev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com