Ultrafine mixed sand concrete by using additive

A technology for mixing sand and concrete, applied in the field of building materials, can solve the problems of intensifying the exploitation and use of rare resources such as natural medium sand, increasing the drying shrinkage of concrete, and low application scope, achieving significant social and environmental benefits, The effect of small slump loss and satisfactory mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Mixing ratio (extra fine sand:crumbs) tight porosity 3:7 28% 4:6 38% 5:5 32% 6:4 35%

[0029] It can be seen from the comparison of the above lists that when the fineness modulus of the ultra-fine sand is 0.8, the compounding ratio of ultra-fine sand and debris is the most ideal of 4:6.

Embodiment 2

[0031] Mixing ratio (extra fine sand:crumbs) tight porosity 3:7 33% 4:6 33% 5:5 33% 6:4 36%

[0032] It can be seen from the comparison of the above list that when the fineness modulus of the ultra-fine sand is 1.0, the compounding ratio of ultra-fine sand and debris is the most ideal of 3:7.

Embodiment 3

[0034] Mixing ratio (extra fine sand:crumbs) tight porosity 3:7 30% 4:6 31% 5:5 32% 6:4 31%

[0035] It can be seen from the comparison of the above lists that when the fineness modulus of the ultra-fine sand is 1.2, the compounding ratio of ultra-fine sand and debris is the most ideal of 3:7.

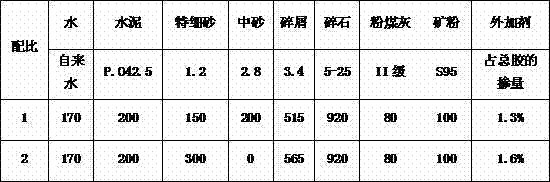

[0036] Through the above experiments, we made the ratio of modified polycarboxylate water reducer to concrete for practical application:

[0037]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com