Capillary crystalline patch plaster

A technology of infiltration crystallization and mortar, applied in the field of building materials, can solve the problems of low strength, long construction period, poor crack resistance, etc., and achieve the effects of excellent bonding performance, short initial setting time, and excellent crack resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

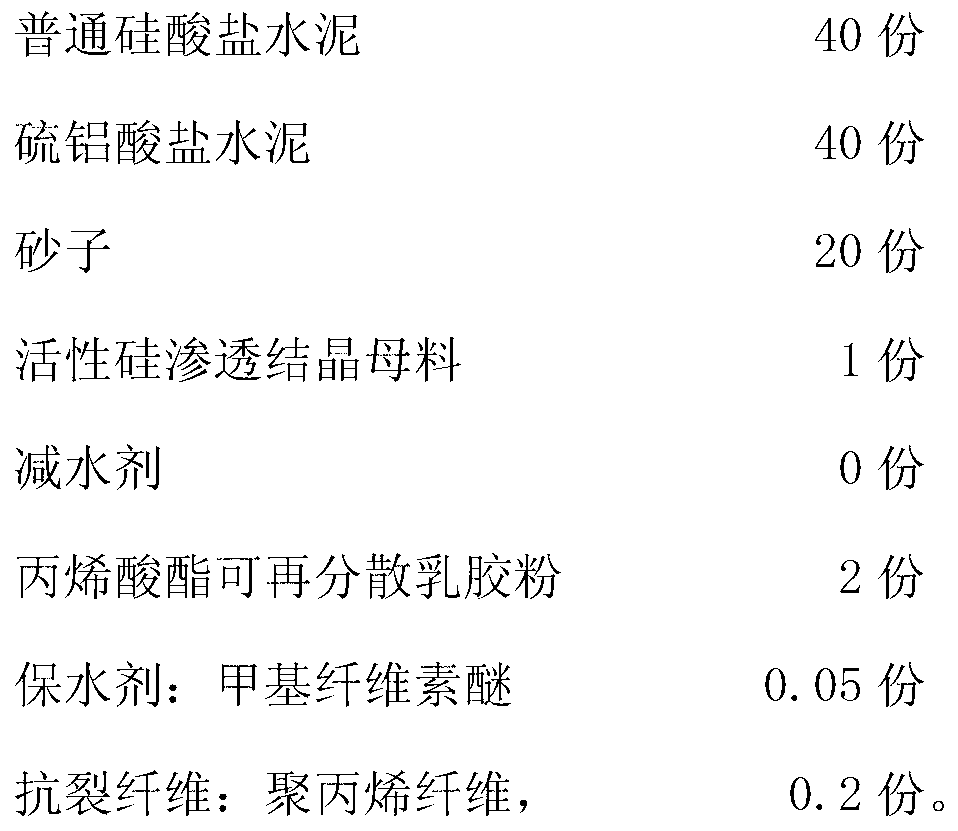

Embodiment 1

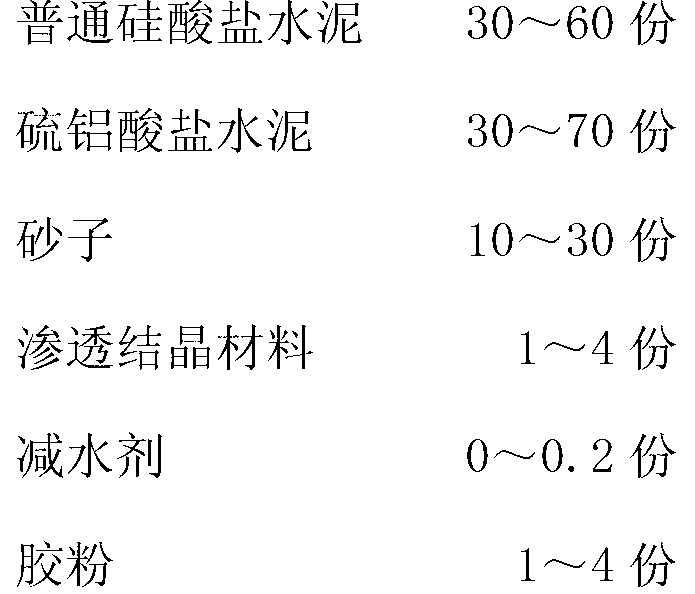

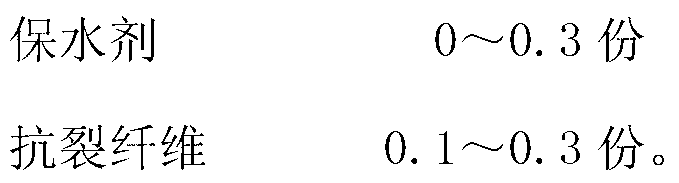

[0021] Permeable crystal repair mortar formula:

[0022]

[0023] Preparation Process:

[0024] Take 40 parts of ordinary Portland cement, 40 parts of sulphoaluminate cement, 20 parts of sand, 1 part of infiltrating crystal masterbatch, 0 of water reducing agent, 2 parts of rubber powder, 0.05 part of water retaining agent, 0.2 part of anti-cracking fiber, in order Add it to the mixer and mix well to make the osmotic crystal repair mortar.

Embodiment 2

[0026]

[0027] Preparation process: Take 40 parts of ordinary Portland cement, 30 parts of sulphoaluminate cement, 30 parts of sand, 1 part of infiltration crystallization masterbatch, 0.05 part of water reducing agent, 1 part of rubber powder, 0.05 part of water retaining agent, 0.2 part of anti-cracking fiber Copies. Add the above-mentioned materials in the mixer one by one and mix them evenly to make an infiltrating crystal repair mortar.

Embodiment 3

[0029]

[0030] Preparation process: Take the formula amount of ordinary Portland cement, sulphoaluminate cement, sand, infiltration crystallization masterbatch, water reducing agent, rubber powder, water retention agent, anti-cracking fiber, and add them to the mixer in turn, and mix them evenly. Make infiltration crystal repair mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com