Environment-friendly universal color paste and preparation method thereof

An environmentally friendly, color paste technology, applied in the direction of pigment paste, etc., can solve the problems of light resistance, poor weather resistance, poor color reproducibility, coarse pigment particles, etc., to achieve strong weather resistance, good production operability, and difficult layered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

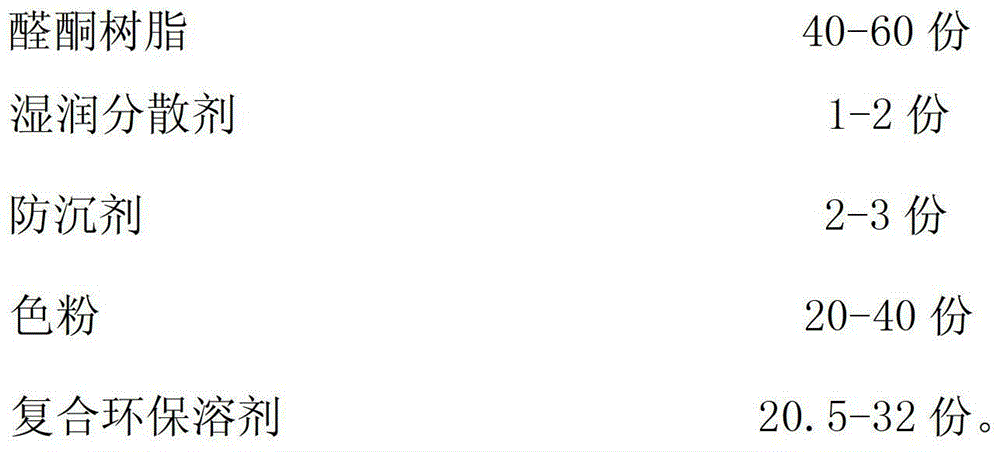

[0029] The preparation method of the above-mentioned environment-friendly universal color paste comprises the following steps in sequence:

[0030] 1) At 600-800 rpm, first add 40-60 parts of solid aldehyde and ketone resin and 20-30 parts of environmentally friendly mixed solvent, and mix to make a liquid semi-finished product;

[0031] 2) Add 1-2 parts of wetting and dispersing agent, 2-3 parts of anti-sedimentation agent, 20-40 parts of pigment toner to the mixed liquid semi-finished product, and mix well;

[0032] 3) Grind with a sand mill to disperse the mixture until the fineness is ≤20um;

[0033] 4) Use 0.5-2 parts of compound environmental protection solvent to supplement the solvent loss in the production process;

[0034] 5) Filtration to obtain the desired product of the present invention.

[0035] (2) Embodiment:

[0036] The embodiment adopts different toners to make different color pastes, and according to the physical and chemical properties of the toners, t...

Embodiment 1

[0038] A new type of bright red pulp, which is made of the following raw materials in weight ratio:

[0039]

[0040] The preparation method of above-mentioned bright red pulp comprises the following steps carried out in sequence:

[0041] 1) At 700 rpm, first add 50 parts of solid aldehyde and ketone resin and 20 parts of environmentally friendly mixed solvent, and mix them into a liquid semi-finished product;

[0042] 2) Add 2 parts of wetting and dispersing agent, 3 parts of anti-settling agent, and 25 parts of bright red powder into the mixed liquid semi-finished product, and mix well;

[0043] 3) Grind with a sand mill to disperse the mixture until the fineness is ≤20um;

[0044] 4) Use 1 part of compound environmental protection solvent to supplement the solvent loss in the production process;

[0045] 5) Filtrate to obtain the required new bright red pulp;

[0046] 6) See the table below for technical indicators.

Embodiment 2

[0048] A new type of iron red paste, which is made of the following raw materials in weight ratio:

[0049]

[0050] The preparation method of above-mentioned iron red slurry comprises the following steps carried out in sequence:

[0051] 1) At 600 rpm, first add 40 parts of solid aldehyde and ketone resin and 30 parts of environmentally friendly mixed solvent, and mix them into a liquid semi-finished product;

[0052] 2) Add 2 parts of wetting and dispersing agent, 3 parts of anti-sedimentation agent, and 35 parts of iron red powder into the mixed liquid semi-finished product, and mix well;

[0053] 3) Grind with a sand mill to disperse the mixture until the fineness is ≤20um;

[0054] 4) Use 1.8 parts of compound environmental protection solvent to supplement the solvent loss in the production process;

[0055] 5) Filter to obtain the required new iron red slurry;

[0056] 6) See the table below for technical indicators.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com