PU (Poly Urethane) wear-resistant coating

A wear-resistant coating, the technology of group A, applied in the direction of polyurea/polyurethane coatings, coatings, etc., to achieve the effect of prolonging the service life, reducing the friction coefficient, and improving the hardness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

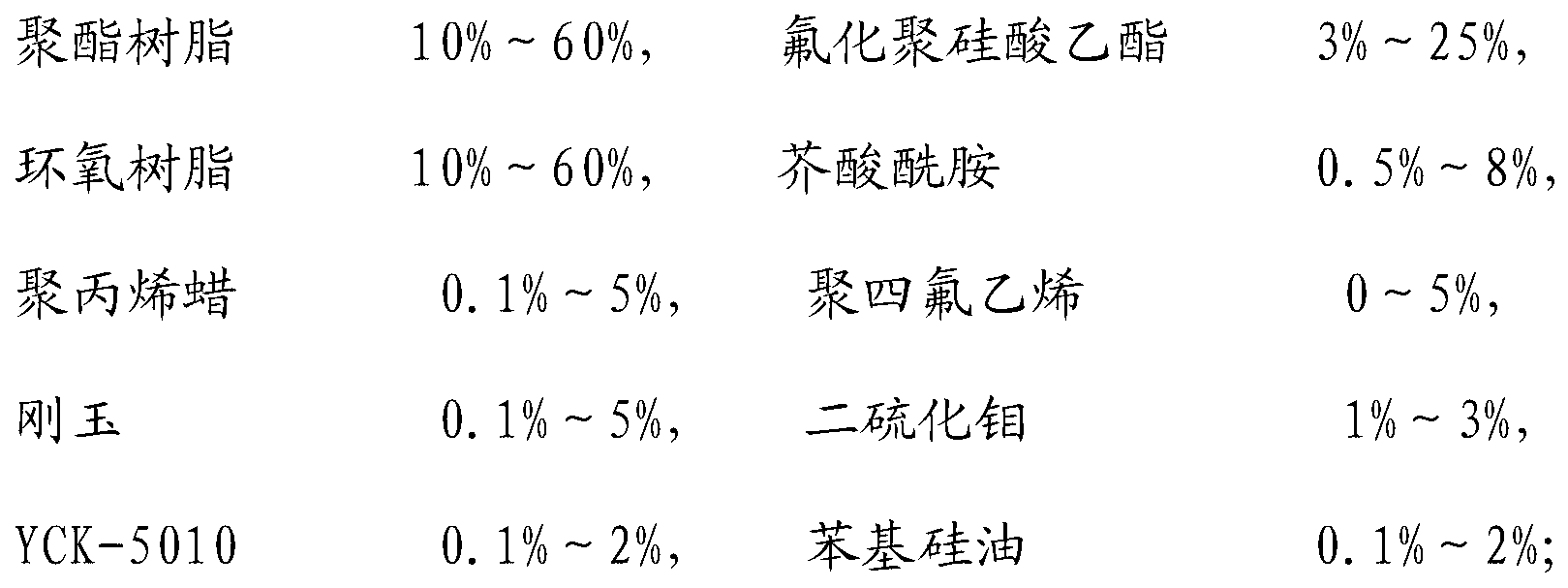

[0022] A kind of PU wear-resisting paint, comprises A component and B component of packing separately, and the weight percent of A component is:

[0023]

[0024] The preparation of the fluorinated polyethyl silicate comprises the following steps: taking 10-60 parts by weight of ethyl silicate with a silicon dioxide content of 28% and putting it into a reaction kettle, stirring and slowly adding 2-25 parts by weight 35% fluorosilicic acid solution, react at a temperature ranging from 25 to 80°C for 1-5 hours to form fluorinated polyethyl silicate.

[0025] The preparation of the A component comprises the following steps:

[0026] Put the polyester resin into the kettle, start stirring, then slowly put erucamide, polypropylene wax and polytetrafluoroethylene into the kettle respectively, stir for 1-2 hours to form a uniformly dispersed slurry, and then put the fluorinated polysilicic acid Ethyl ester, epoxy resin, corundum, molybdenum disulfide, YCK-5010 and phenyl silicone...

Embodiment 2

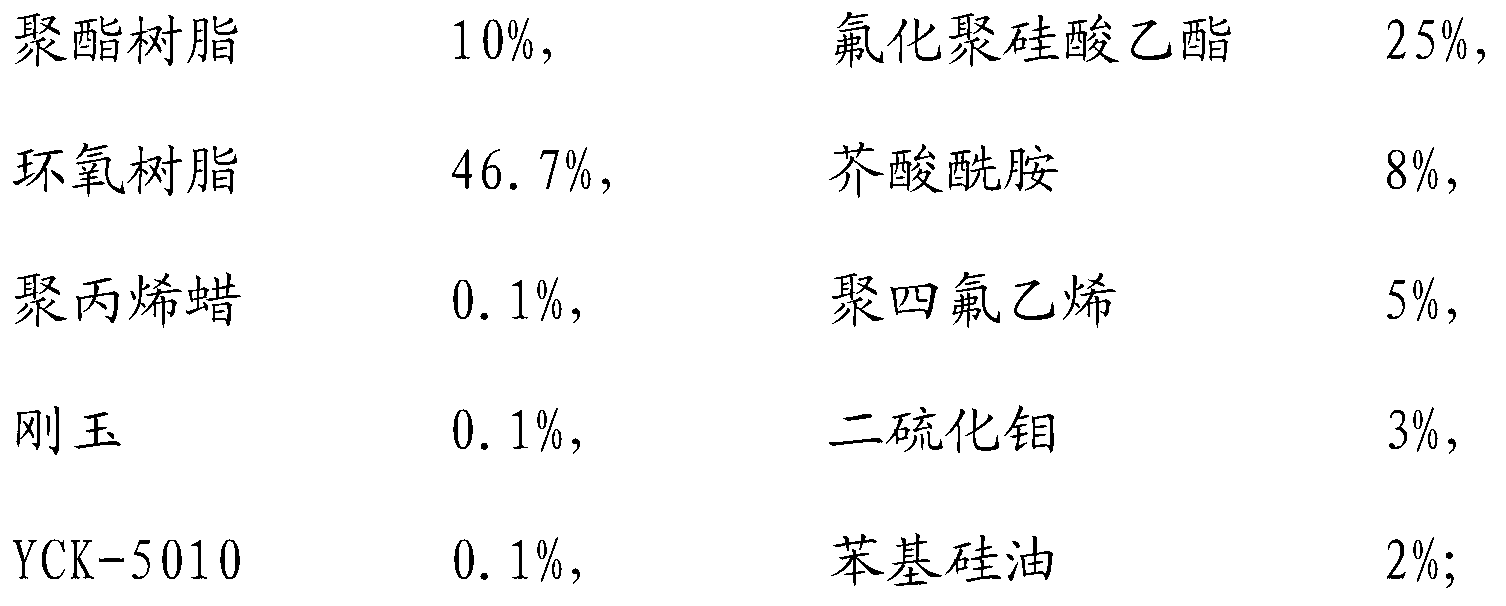

[0031] A kind of PU wear-resisting paint, comprises A component and B component of packing separately, and the weight percent of A component is:

[0032]

[0033] The preparation of the fluorinated polyethyl silicate comprises the following steps: taking 10-60 parts by weight of ethyl silicate with a silicon dioxide content of 28% and putting it into a reaction kettle, stirring and slowly adding 2-25 parts by weight 35% fluorosilicic acid solution, react at a temperature ranging from 25 to 80°C for 1-5 hours to form fluorinated polyethyl silicate.

[0034] The preparation of the A component comprises the following steps:

[0035] Put the polyester resin into the kettle, start stirring, then slowly put erucamide, polypropylene wax and polytetrafluoroethylene into the kettle respectively, stir for 1-2 hours to form a uniformly dispersed slurry, and then put the fluorinated polysilicic acid Ethyl ester, epoxy resin, corundum, molybdenum disulfide, YCK-5010 and phenyl silicone...

Embodiment 3

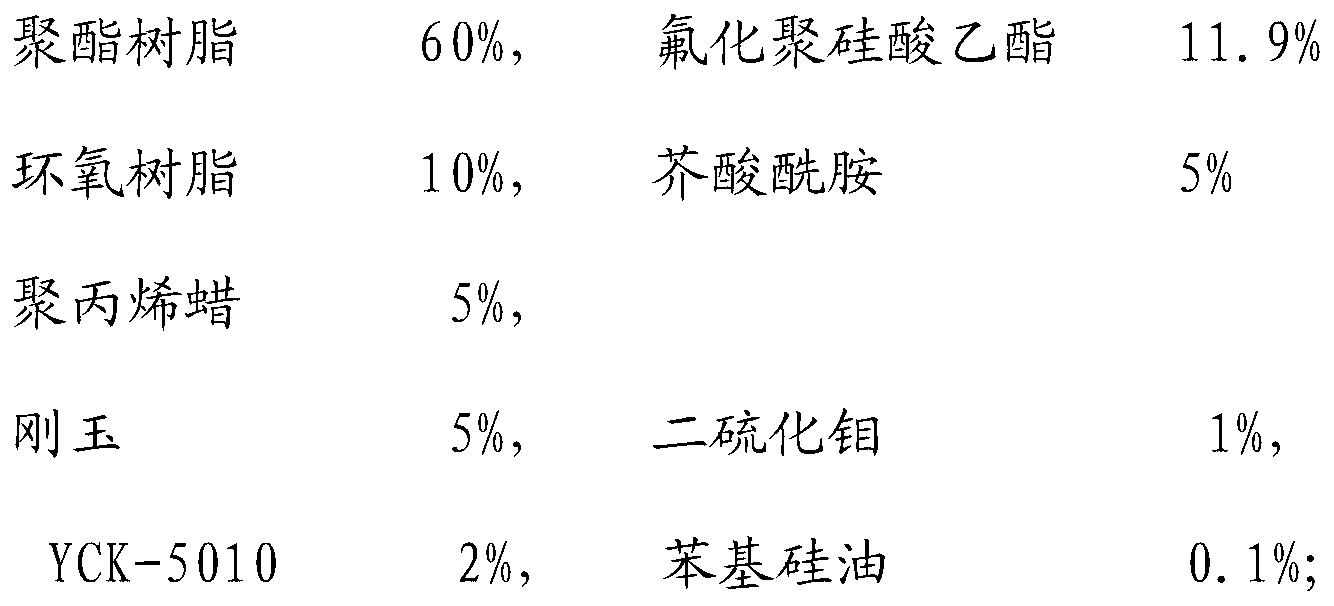

[0039] A kind of PU wear-resistant paint, comprises A component and B component of packaging separately, and A component is made by following weight percentage:

[0040]

[0041] The preparation of the fluorinated polyethyl silicate comprises the following steps: taking 10-60 parts by weight of ethyl silicate with a silicon dioxide content of 28% and putting it into a reaction kettle, stirring and slowly adding 2-25 parts by weight 35% fluorosilicic acid solution, react at a temperature ranging from 25 to 80°C for 1-5 hours to form fluorinated polyethyl silicate.

[0042] The preparation of the A component comprises the following steps:

[0043] Put the polyester resin into the kettle, start stirring, then slowly put erucamide, polypropylene wax and polytetrafluoroethylene into the kettle respectively, stir for 1-2 hours to form a uniformly dispersed slurry, and then put the fluorinated polysilicic acid Ethyl ester, epoxy resin, corundum, molybdenum disulfide, YCK-5010 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com