Preparation method of light/humidity dual-curing polyurethane hot melt adhesive

A polyurethane hot-melt adhesive and dual-cure technology, which is applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve problems such as low curing degree, not particularly strong strength, and poor wetting force , to achieve the effect of prolonging the opening time, shortening the opening time and improving the initial strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

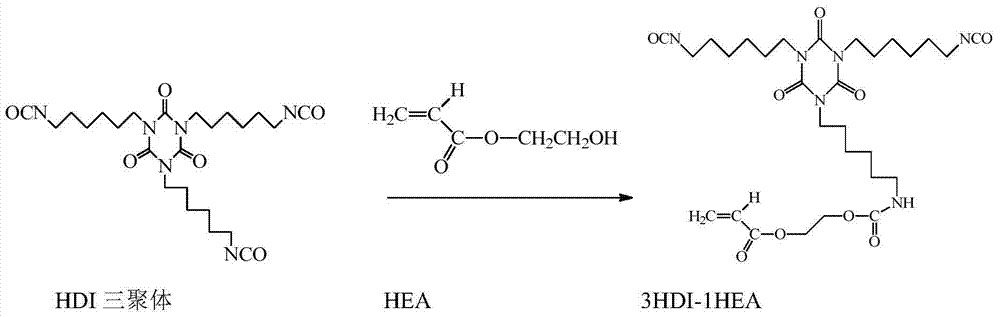

[0038] 1) Preparation of mixed isocyanate 3HDI-1HEA / HDI

[0039] In a four-neck flask with agitator, dropping funnel, condenser and thermometer, add HDI trimer (6.00g, 0.01mol, 21% isocyanate content, Japan Polyurethane Industry Co., Ltd.), and keep warm at 60°C , the speed is controlled at 120r / min, and N 2 Get rid of water vapor and protect the reaction to carry out, add 0.04g p-hydroxyanisole (polymerization inhibitor) in four-necked flask, 0.007g dibutyltin dilaurate (reaction catalyst), drop the HEA (1.16g, 0.01mol ), and control the temperature rise not to exceed 70°C. After the dropwise addition was completed, the temperature was raised to 90°C, reacted at the reaction temperature for 3 hours, and then the heating was stopped (at this time, the product number: 3HDI-1HEA, the preparation reaction equation is as follows), and the measured amount of HDI (6.75g, 0.04mol, isocyanate Acid radical content 49.8%), after stirring evenly, discharge and seal, and set aside, prod...

Embodiment 2

[0046] 1) Preparation of mixed isocyanate 3HDI-1HEA / TDI-100

[0047] In a four-neck flask with agitator, dropping funnel, condenser and thermometer, add HDI trimer (6.00g, 0.01mol, 21% isocyanate content, Japan Polyurethane Industry Co., Ltd.), and keep warm at 60°C , the speed is controlled at 120r / min, and N 2 Get rid of water vapor and protect the reaction to carry out, add 0.04g p-hydroxyanisole (polymerization inhibitor) in four-necked flask, 0.007g dibutyltin dilaurate (reaction catalyst), drop the HEA (1.16g, 0.01mol ), and control the temperature rise not to exceed 70°C. After the dropwise addition, raise the temperature to 90°C, react at the reaction temperature for 3h, then stop heating (the product number at this time: 3HDI-1HEA), and immediately add the measured TDI-100 (6.97g, 0.04mol, isocyanate content 48.2 %), stir evenly and then discharge and seal, ready for use, product number: 3HDI-HEA / TDI-100, wherein the molar ratio of 3HDI-1HEA to TDI-100 is 20:80.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com