Preparation method of 6lif/10b4c composite neutron conversion thin film for 4h-sic based neutron detector

A 10B4C, neutron detector technology, applied in metal material coating process, ion implantation plating, coating and other directions, can solve the problems of film layer peeling and interface bonding performance deterioration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

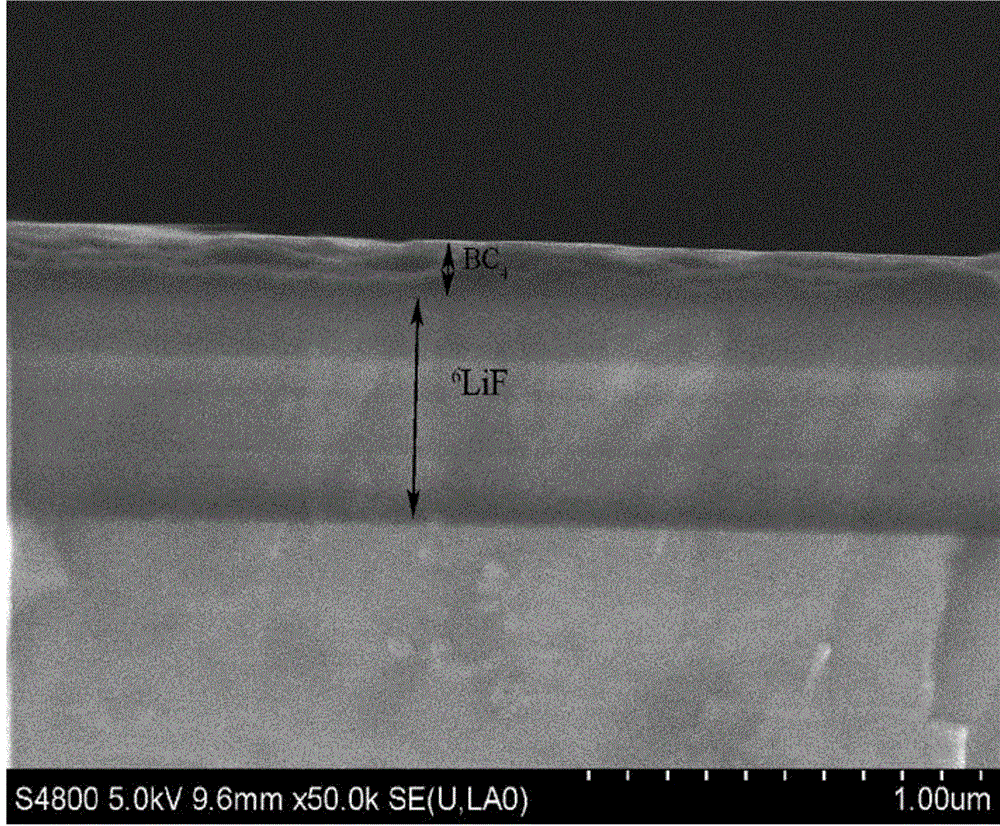

[0028] The 4H-SiC based neutron detector of the present embodiment is used 6 LiF / 10 B 4 C Composite conversion thin film preparation process is as follows:

[0029] a. Put the substrate material 4H-SiC matrix into acetone and absolute ethanol in sequence for 20 minutes of ultrasonic cleaning, take out and dry after fully cleaning;

[0030] b. The single crystal 4H-SiC substrate cleaned in step a, 6 Li concentration of 90% 6 LiF target and 10 B concentration of 96% 10 B 4 The C target is placed in the vacuum chamber of the reactive magnetron sputtering coating vacuum furnace, and then vacuumed to 5.0×10 -4 Pa, the impurities in the single crystal 4H-SiC substrate were removed by biased reverse sputtering cleaning, the power of reverse sputtering cleaning was 120 W, and the bias voltage was -500 V; the impurities were removed by pre-sputtering cleaning 6 LiF target and 10 B 4 C target impurity, pre-sputter cleaning power is 120 W, bias voltage is -100 V; reverse spu...

Embodiment 2

[0036] The 4H-SiC based neutron detector of the present embodiment is used 6 LiF / 10 B 4 C Composite conversion film preparation process is basically the same as in Example 1, the difference is that the reaction magnetron sputtering coating vacuum furnace is evacuated to 4.0 × 10 -4Pa, the power of reverse sputter cleaning is 100 W, the bias voltage is -400 V; the power of pre-sputter cleaning is 100 W, the bias voltage is -100 V, the flow rate of argon gas is 160 Sccm, reverse sputter cleaning and pre-sputter cleaning The vacuum degree of sputter cleaning operation is 1.5 Pa absolute pressure. The power of sputtering deposition is 100 W, the flow rate of argon gas is 150 Sccm, and the vacuum degree of sputtering deposition operation is an absolute pressure of 0.43 Pa; 10 B 4 The C coating sputtering deposition operation process is a continuous operation process. sputter deposition 6 LiF / 10 B 4 The thicknesses of the C coatings were 1.5 μm and 0.5 μm, respectively, an...

Embodiment 3

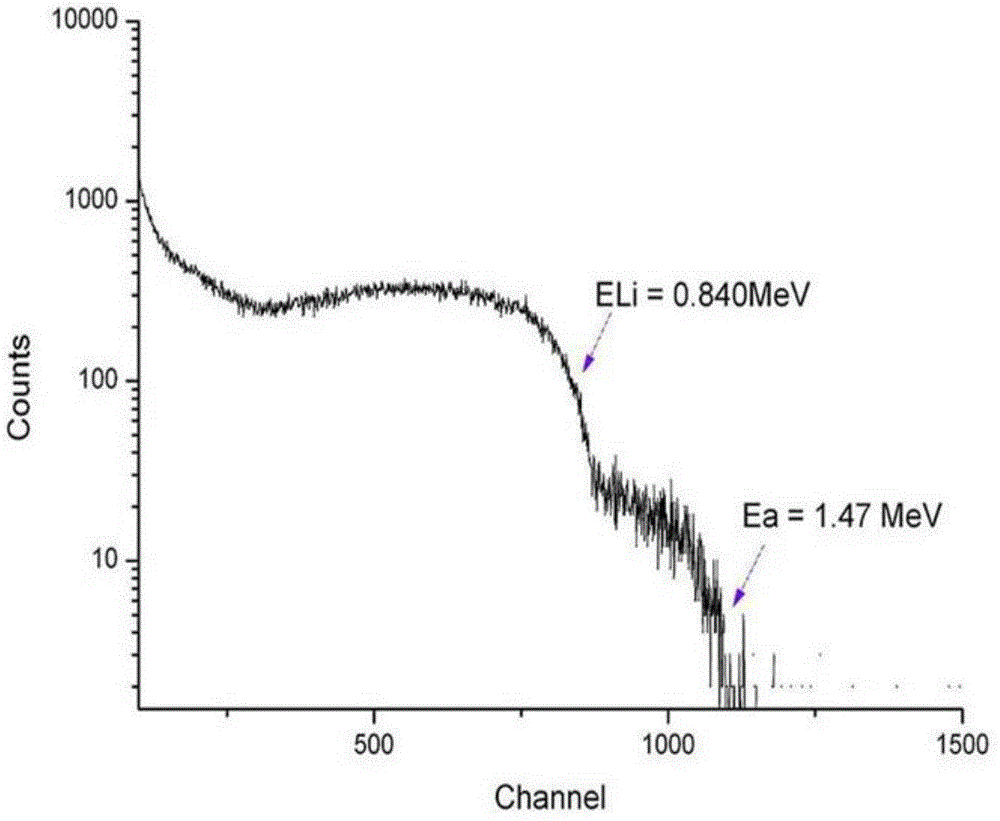

[0038] in deposition 6 LiF / 10 B 4 C composite conversion film process, deposition 6 LiF and 10 B 4 The thickness of the C coating also affects the detection efficiency of the detector. This example 6 LiF / 10 B 4 Coating equipment and other processing conditions used for the preparation of C conversion film are all the same as in Example 1, and keep 6 LiF / 10 B 4 The total thickness of C composite conversion film is controllable at 2.0 μm, which is selected during deposition 6 LiF coating thickness is 1.0 μm, 10 B 4 The thickness of the C coating is 1.0 μm, and the prepared conversion film layer can also pass through 6 Li(n,α) 3 H and 10 B(n, α) 7 α produced by Li reaction, 7 Li and T particle energy spectrum test the incident neutron signal to improve the detection efficiency.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com