NiO-based dilute magnetic semiconductor nanofiber and preparation method thereof

A dilute magnetic semiconductor and nanofiber technology, applied in the field of material science, can solve the problem of the lack of research reports on the one-dimensional structure of NiO dilute magnetic semiconductor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

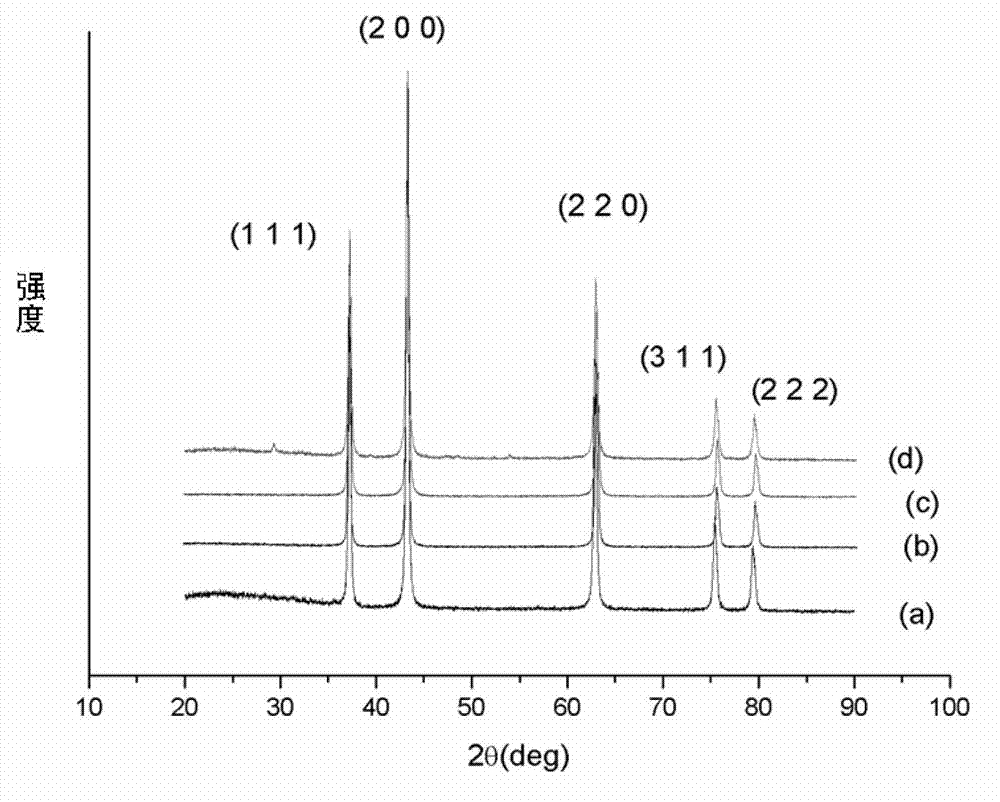

Embodiment 1

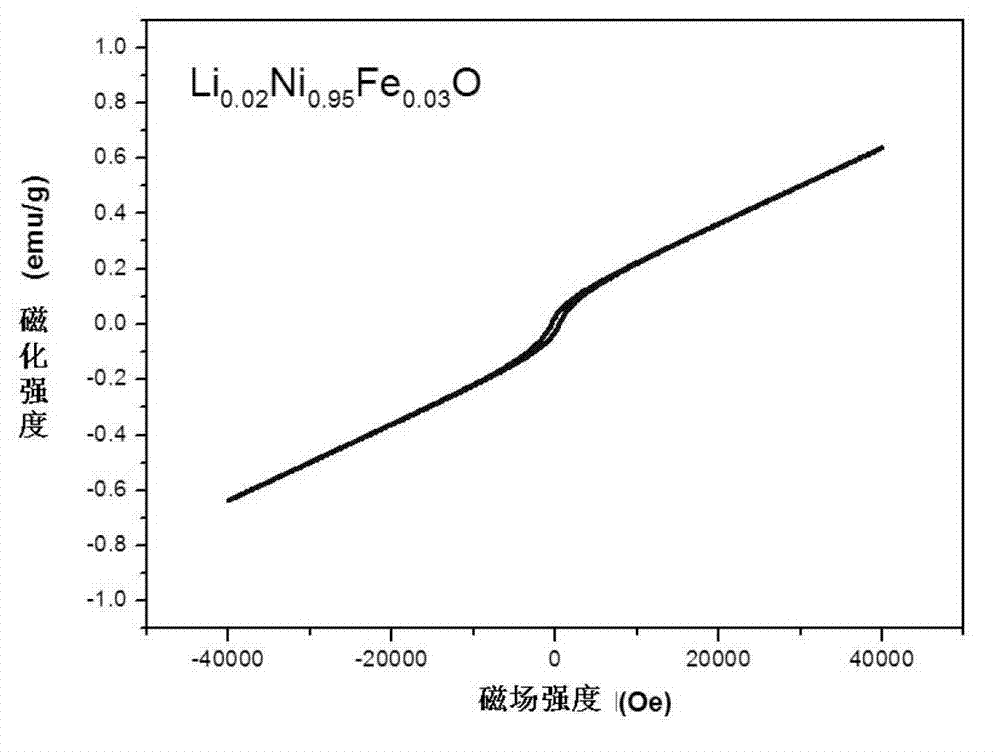

[0041] Raw materials: analytically pure nickel acetate (Ni(Ac) 2 4H 2 O), ethanol, iron nitrate (Fe(NO 3 ) 3 9H 2 O), lithium nitrate (LiNO 3 ), polyvinylpyrrolidone (PVP) with a relative molecular mass of 1.3 million;

[0042] Prepare precursor solution: weigh 0.450g nickel acetate (Ni(Ac) 2 4H 2 O), 0.023g iron nitrate (Fe(NO 3 ) 3 9H 2 O), 0.002g lithium nitrate (LiNO 3 ). Nickel acetate (Ni(Ac) 2 4H 2 O), join in the ethanol, stir about half an hour to dissolve completely, the solution is light green. Then add iron nitrate (Fe(NO 3 ) 3 9H 2 O), lithium nitrate (LiNO 3 ), polyvinylpyrrolidone (PVP), and stirred for 10 hours to obtain a uniform and viscous precursor solution. The molar ratio of nickel, iron, and lithium in the precursor solution was 95:3:2.

[0043] Electrospinning: put the prepared precursor solution into a 10ml needle tube, use a No. 7 injection needle (needle tip ground flat), the spinning voltage is 13.5kV, and the receiving distance is...

Embodiment 2

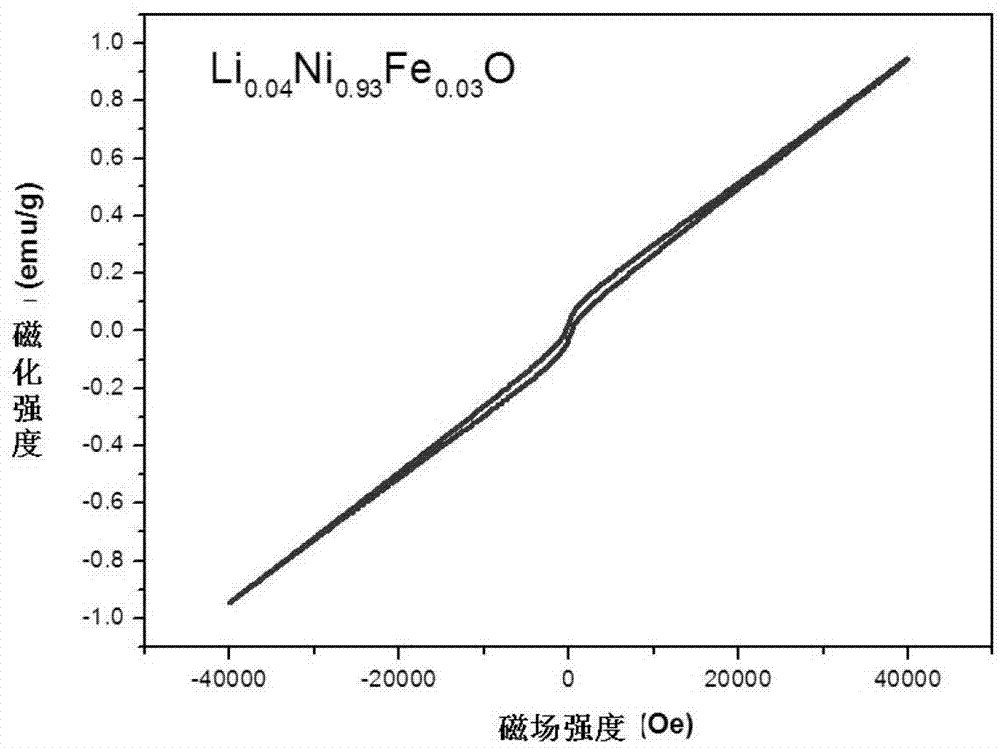

[0046] Raw materials: analytically pure nickel acetate (Ni(Ac) 2 4H 2 O), ethanol, iron nitrate (Fe(NO 3 ) 3 9H 2 O), lithium nitrate (LiNO 3 ), polyvinylpyrrolidone (PVP) with a relative molecular mass of 1.3 million;

[0047] Prepare precursor solution: weigh 0.45g nickel acetate (Ni(Ac) 2 4H 2 O), 0.024g iron nitrate (Fe(NO 3 ) 3 9H 2 O), 0.05g lithium nitrate (LiNO 3 ). Nickel acetate (Ni(Ac) 2 4H 2 O), join in the ethanol, stir about half an hour to dissolve completely, the solution is light green. Then add iron nitrate (Fe(NO 3 ) 3 9H 2 O, lithium nitrate (LiNO 3 ), polyvinylpyrrolidone (PVP), and stirred for 10 hours to obtain a uniform and viscous precursor solution. The molar ratio of nickel, iron, and lithium in the precursor solution was 93:3:4.

[0048] Electrospinning: The method of this step is the same as that in Example 1.

[0049] Through the above method, NiO-based nanofibers can be obtained. The fiber can be expressed as Li 0.04 Ni 0.93...

Embodiment 3

[0051] Raw materials: analytically pure nickel acetate (Ni(Ac) 2 4H 2 O), ethanol, iron nitrate (Fe(NO 3 ) 3 9H 2 O), lithium nitrate (LiNO 3 ), polyvinylpyrrolidone (PVP) with a relative molecular mass of 1.3 million;

[0052] Prepare precursor solution: weigh 0.45g nickel acetate (Ni(Ac) 2 4H 2 O), 0.024g iron nitrate (Fe(NO 3 ) 3 9H 2 O), 0.008g lithium nitrate (LiNO 3 ). Nickel acetate (Ni(Ac) 2 4H 2 O), join in the ethanol, stir about half an hour to dissolve completely, the solution is light green. Then add iron nitrate (Fe(NO 3 ) 3 9H 2 O), lithium nitrate (LiNO 3), polyvinylpyrrolidone (PVP), and stirred for 10 hours to obtain a uniform and viscous precursor solution. The molar ratio of nickel, iron, and lithium in the precursor solution was 91:3:6.

[0053] Electrospinning: The method of this step is the same as that in Example 1.

[0054] Through the above method, NiO-based nanofibers can be obtained, which can be expressed as Li 0.06 Ni 0.91 Fe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com