Double-mass flywheel for double-clutch automatic speed changer

A technology of automatic transmission and dual-mass flywheel, which is applied in the direction of flywheel, etc., can solve the problems of large running resistance, difficulty in achieving vibration reduction and vibration isolation, and many friction pairs, so as to overcome the wear gap, avoid torsional vibration resonance of the drive train, eliminate and The effect of body noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

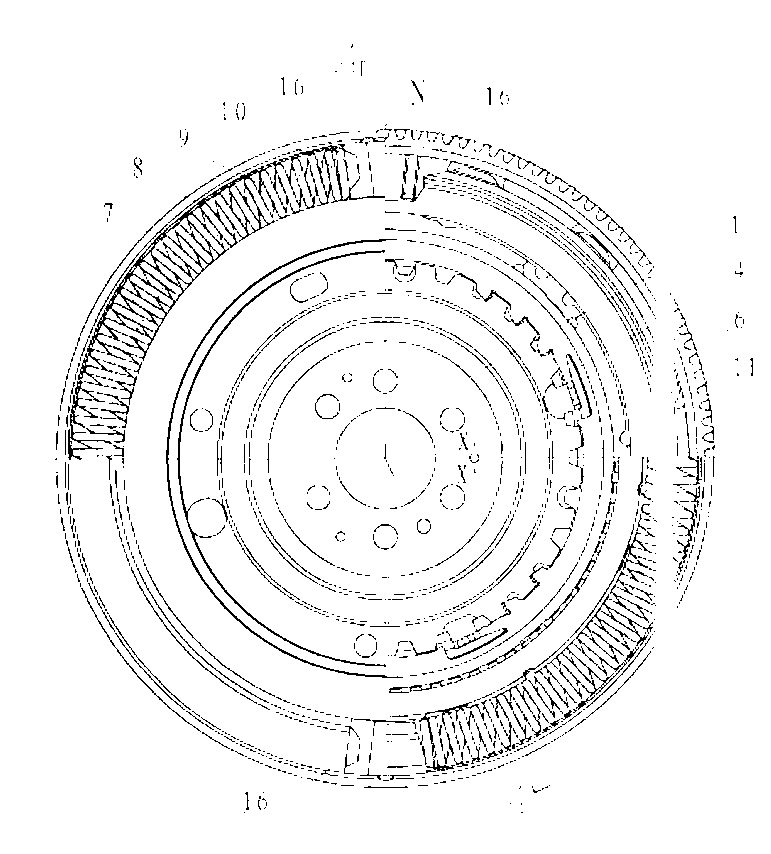

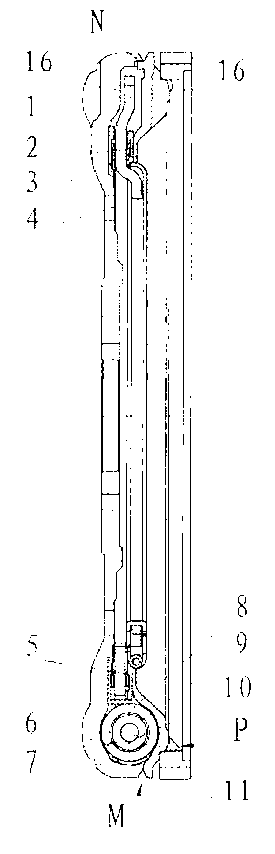

[0016] Such as Figure 1 to Figure 3 As shown, the dual-mass flywheel of the dual-clutch automatic transmission of the present invention includes a main flywheel body 1, an auxiliary flywheel body 6, a flywheel ring gear 11, an intermediate disc assembly 4 (including an intermediate disc 41, an intermediate disc cover 42, and an idle damping spring 43 ), an outer arc spring 8, an inner arc spring 9 (and a spring seat 10) are installed between the main flywheel body 1 and the auxiliary flywheel body 6 (through the arc slideway 7).

[0017] Such as figure 2 As shown, a first damping compression piece 3 and a second damping compression piece 2 are respectively installed between the main flywheel body 1 and the intermediate disk assembly 4, and between the auxiliary flywheel body 6 and the intermediate disk assembly 4. An axial elastic structure is arranged in the middle of the shock absorber composed of main and auxiliary flywheel bodies 1, 6, outer and inner arc springs 8, 9, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com