Multistage Stirling refrigerating machine

A technology of refrigerators and all levels, applied in the directions of refrigerators, refrigeration and liquefaction, compressors, etc., can solve the problems such as the inability to reach the deep refrigeration temperature, increase the refrigeration depth, increase the refrigeration capacity, and increase the number of refrigerator stages Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

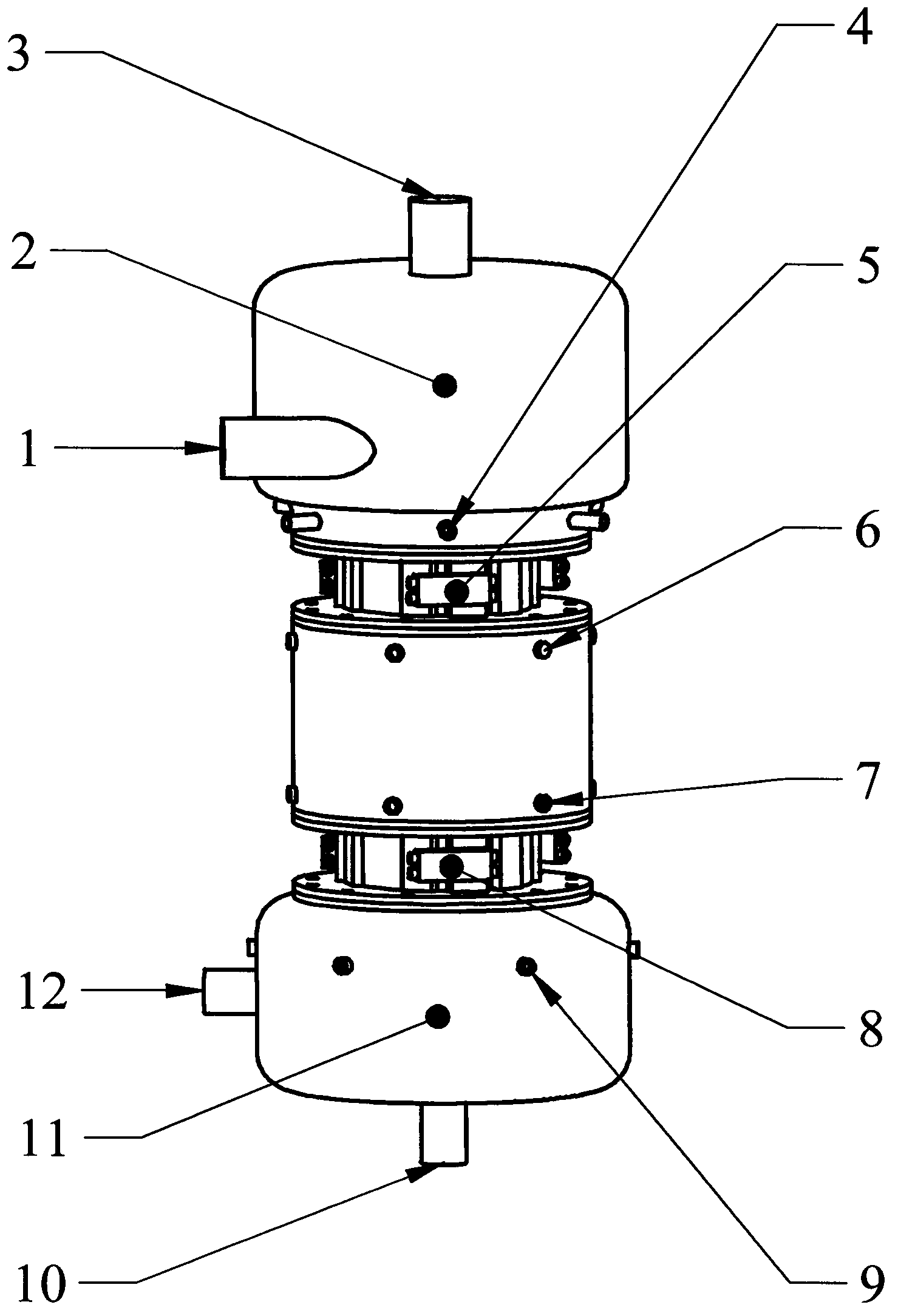

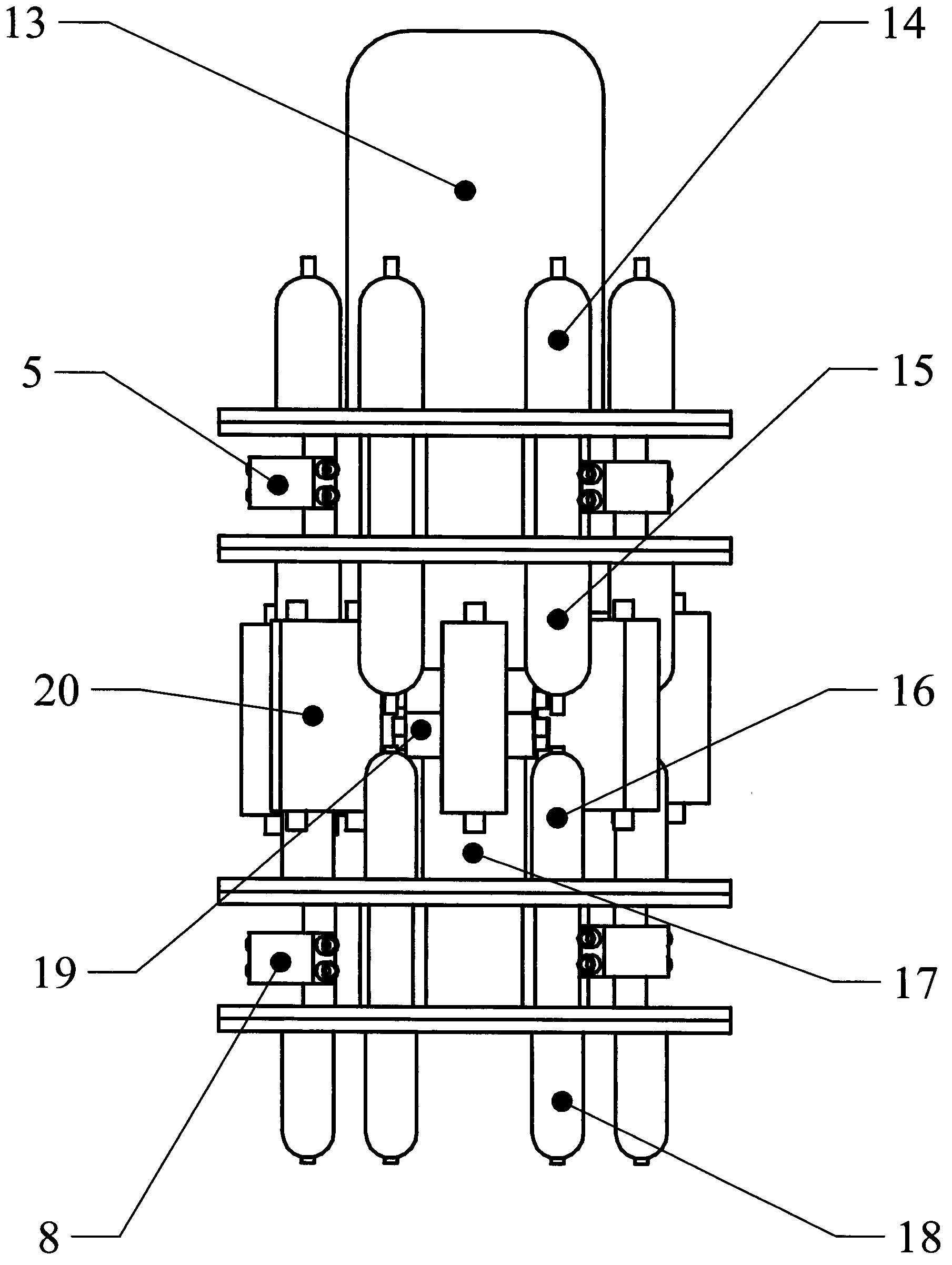

[0017] figure 1 figure 2 The two-stage Stirling refrigerator shown is a double-loop connected Stirling refrigerator with 6 working chambers in each stage, and there are 12 working chambers in total in the two stages. For the production of liquefied natural gas. The electric motor 13 is placed in the center of the heat outflow end 2, and the rotating shaft of the electric motor is coaxial with the rotor shaft of the heat engine of the two-stage refrigerating machine and is connected as a whole. The piston sets of the two-stage Stirling refrigerator are stuck on the rotors of their respective heat engines, and the pistons at both ends are respectively inserted into the heat inflow end cylinder and the heat outflow end cylinder. The coupling channel 17 between the two-stage refrigerators communicates with the secondary sealed chambers of the two-stage refrigerators. A cooling water inlet 1 is provided at the lower part of the side of the heat outflow end 2, and a cooling wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com