Online inspection system for internal resistances of batteries

A storage battery and internal resistance technology, applied in the direction of measuring resistance/reactance/impedance, measuring electricity, measuring electrical variables, etc., can solve the problem of damage to the repeatability accuracy of internal resistance, achieve the effect of improving accuracy, prolonging service life, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

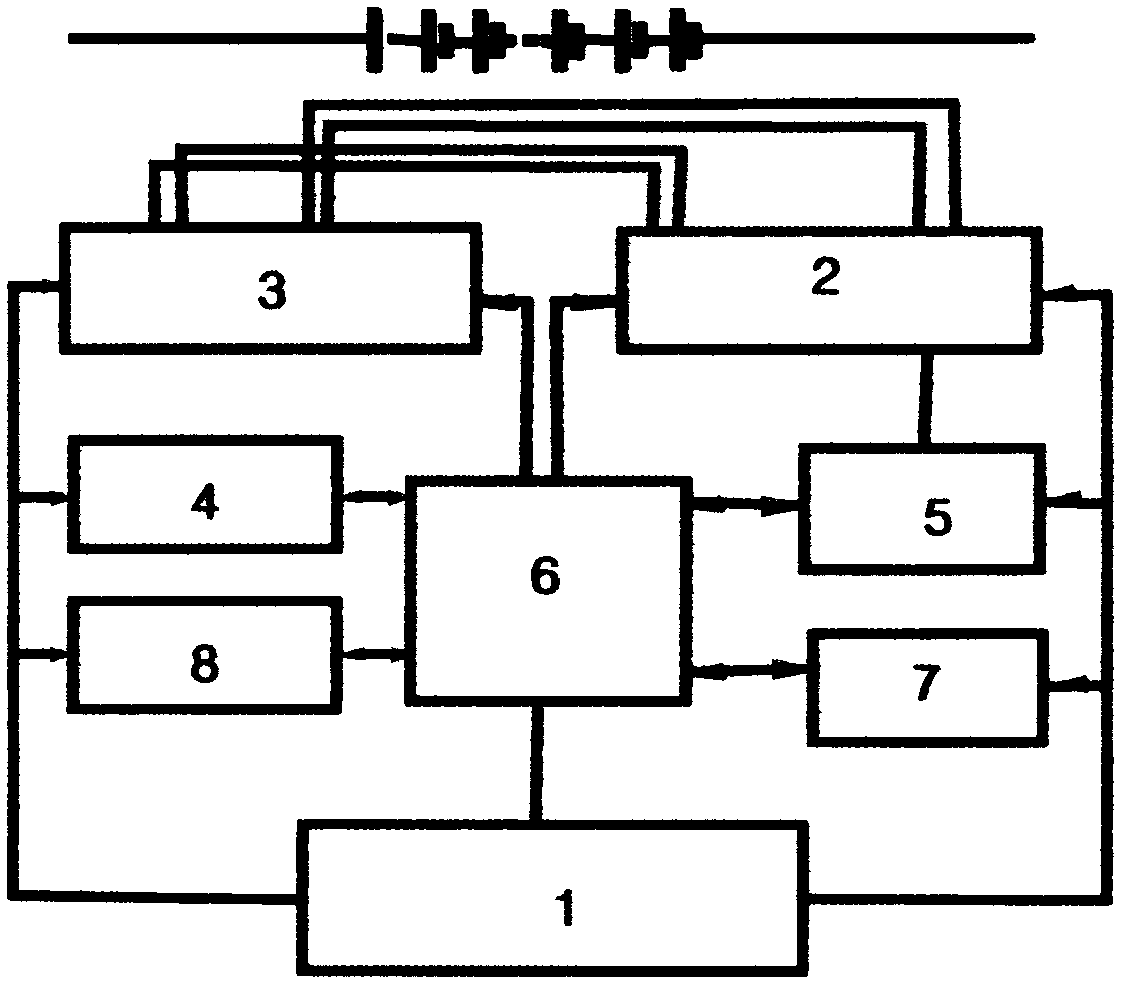

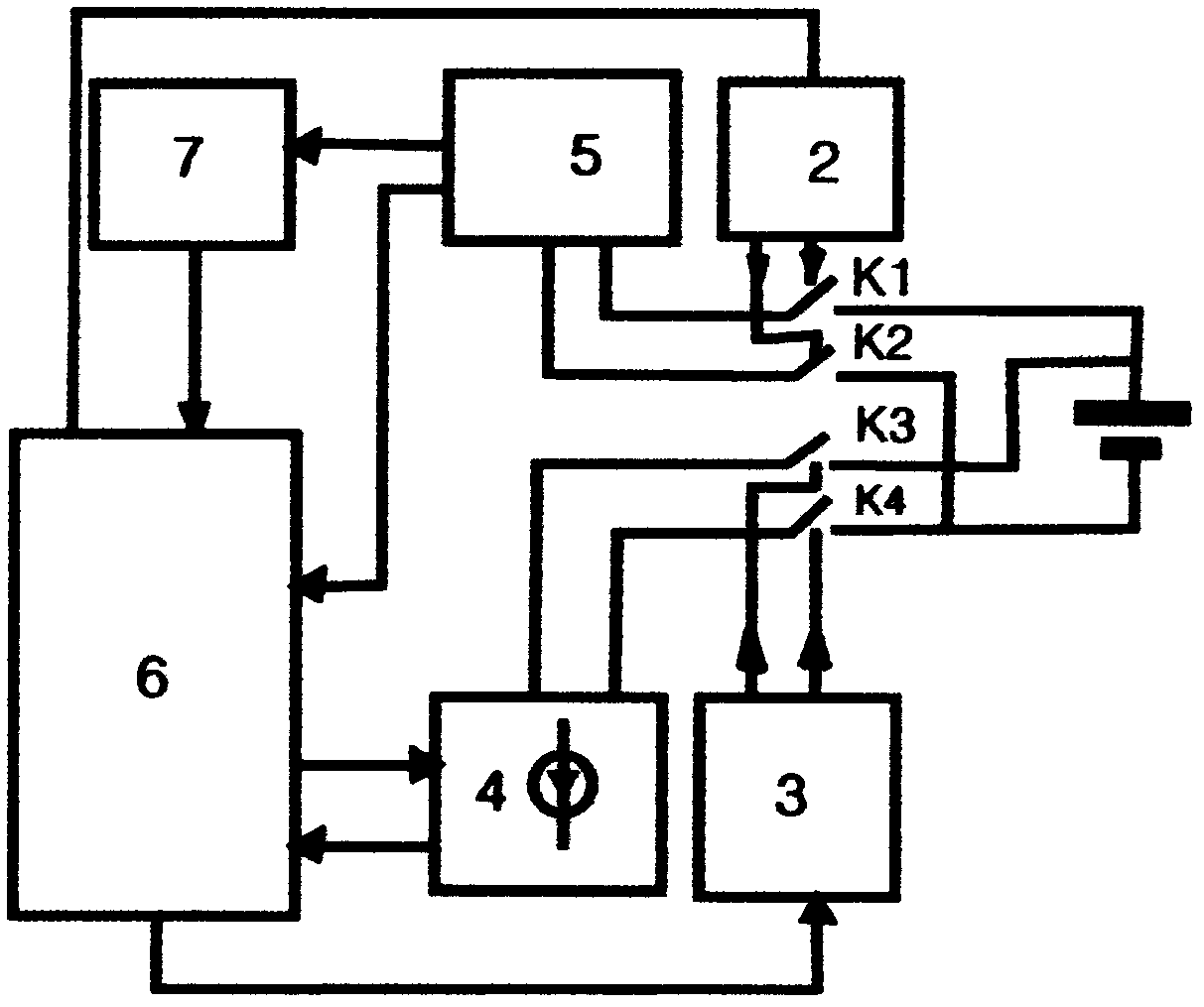

[0020] like figure 1 As shown, the present invention includes a power supply module 1, a voltage inspection control module 2, an internal resistance inspection control module 3, a constant current discharge module 4, a differential acquisition module 5, a microprocessor module 6, an abnormality detection module 7 and a communication module 8 . The internal resistance inspection control module 3 and the voltage inspection control module 2 coordinate and select a single battery channel, so that only one battery is connected to the discharge circuit and the voltage signal acquisition circuit at the same time.

[0021] The constant current discharge module 4 controls the discharge current of the single battery, and the voltage signal of the single battery selected by the voltage inspection control module 2 enters the differential acquisition module 5, which amplifies the voltage signal and converts the voltage signal into a digital signal, transmitted to the microprocessor module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com