Single-phase combined co-phased power supply and transformation structure

A combined technology for power supply and transformation, applied in the field of single-phase combined power supply and transformation structure, can solve the problems of YNd11 wiring traction transformer capacity waste, traction transformer capacity idle, affecting economy, etc., to improve power supply resources and equipment Utilization rate, reduction of one-time investment, and effect of increasing energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

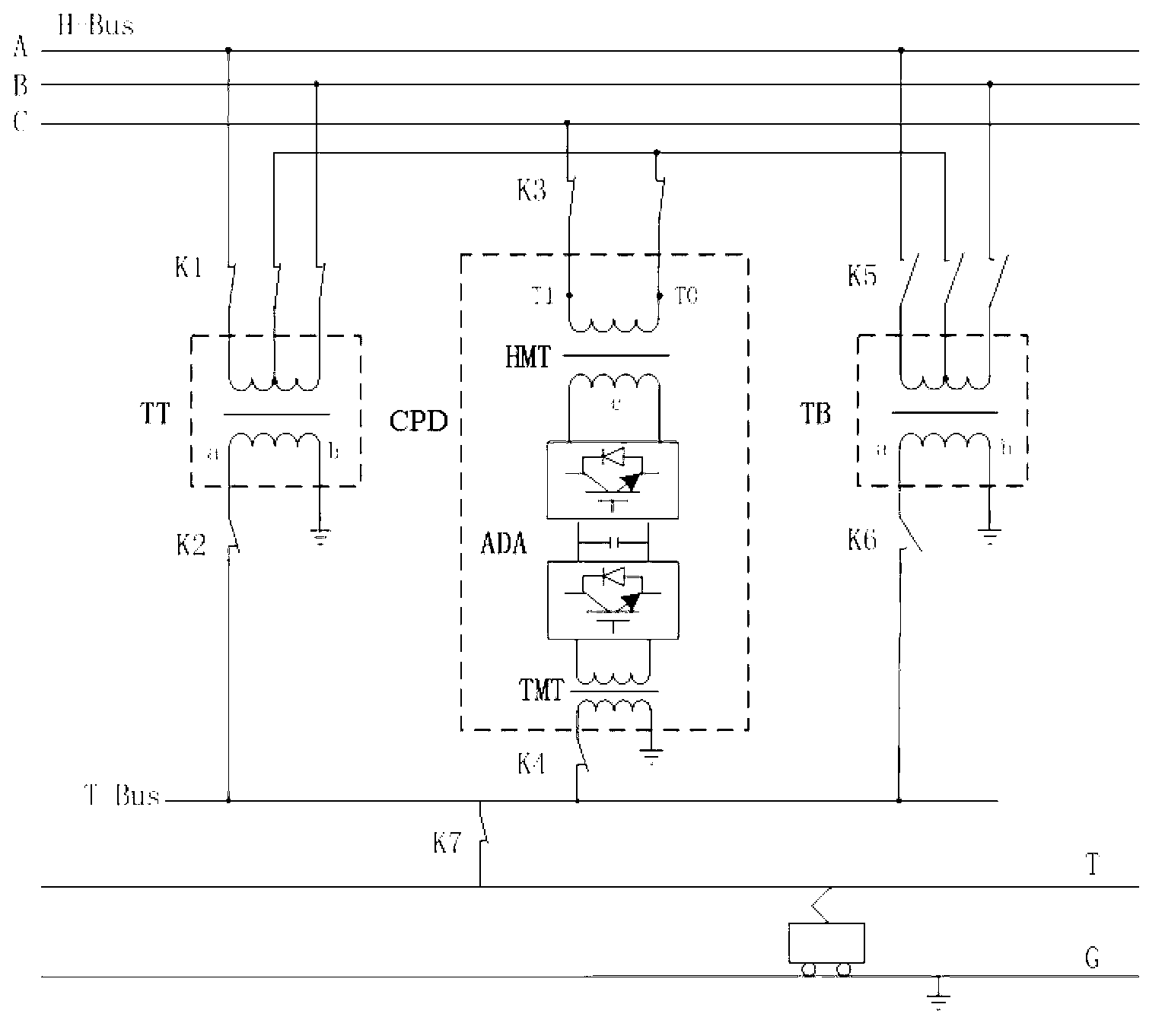

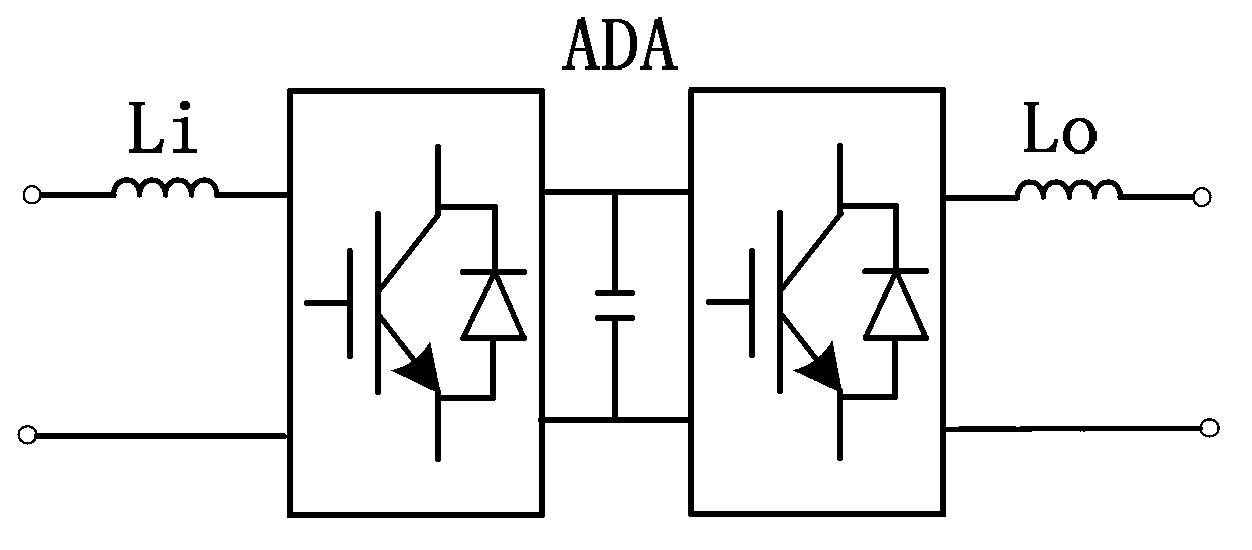

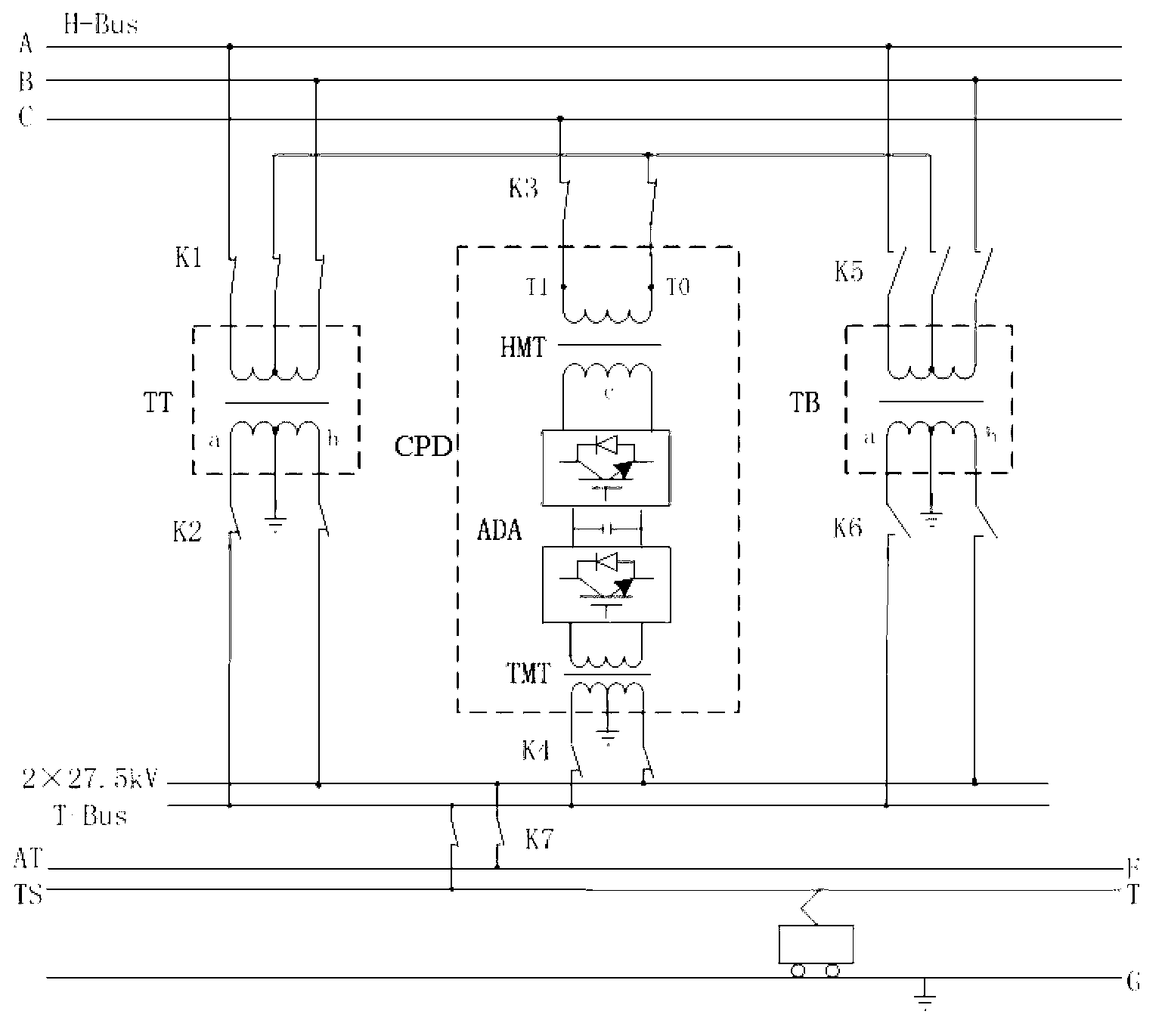

[0030] Such as figure 1 As shown, a schematic diagram of a common-phase power supply and transformation structure, including a traction transformer (TT), a backup traction transformer (TB) and a common-phase compensation device (CPD); the common-phase compensation device (CPD) consists of a high-voltage matching transformer (HMT), an AC-DC-AC ADA and traction matching transformer (TMT); traction transformer (TT), standby traction transformer (TB) and common phase compensation device (CPD) are all single-phase structures; one end of the primary winding of high voltage matching transformer (HMT) T0 is respectively connected to the middle points of the primary windings of the traction transformer (TT) and the standby traction transformer (TB); the primary winding of the traction transformer (TT) and the primary winding of the standby traction transformer (TB) are connected to the high voltage bus H-Bus of the power system The same line voltage, the figure shows the AB line voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com