Washing apparatus, and process for producing porous membrane

A technology of porous membrane and manufacturing method, applied in chemical instruments and methods, membrane, membrane technology, etc., can solve the problems of not being able to obtain sufficient cleaning efficiency, limited cleaning solution speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0391] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples.

[0392] [Test example]

[0393] Hereinafter, test examples will be described.

Embodiment 1

[0427] A porous membrane was formed in the same manner as in Test Example 1.

[0428] Next, warm water heated to 70° C. by a heat exchanger was dropped from a height of 1 m at a flow rate of 2.0 L / min, and the porous membrane with the sinker was put into contact with the water flow to perform cleaning treatment.

[0429] The porous membrane after performing the cleaning treatment for 30 seconds, 60 seconds, or 120 seconds was cut in half and divided into an upstream part and a downstream part. Solvent concentration (C 0 ) and the residual solvent concentration in the porous membrane after cleaning (C 2 ) ~ (C 4 ). The result is as Figure 8 shown.

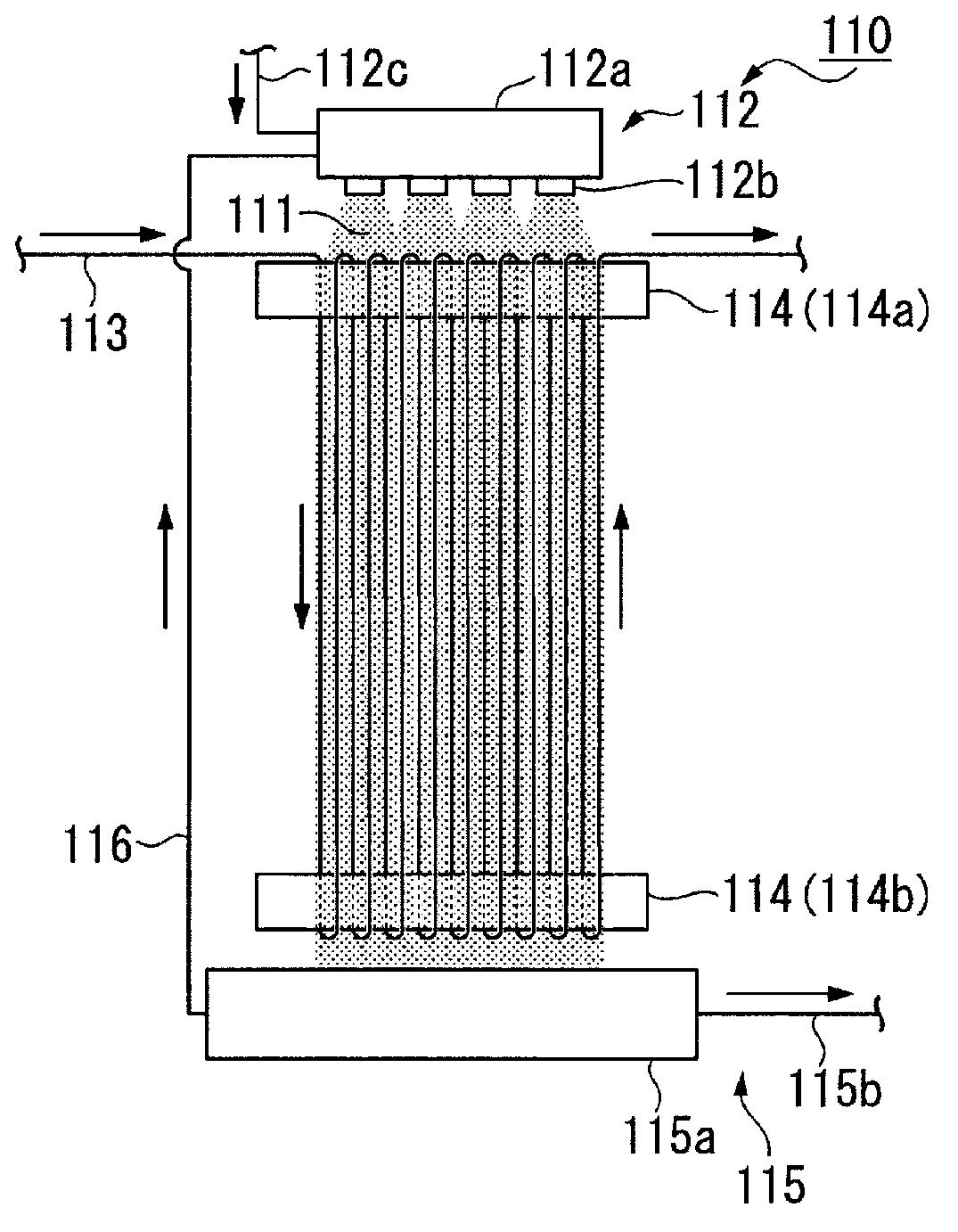

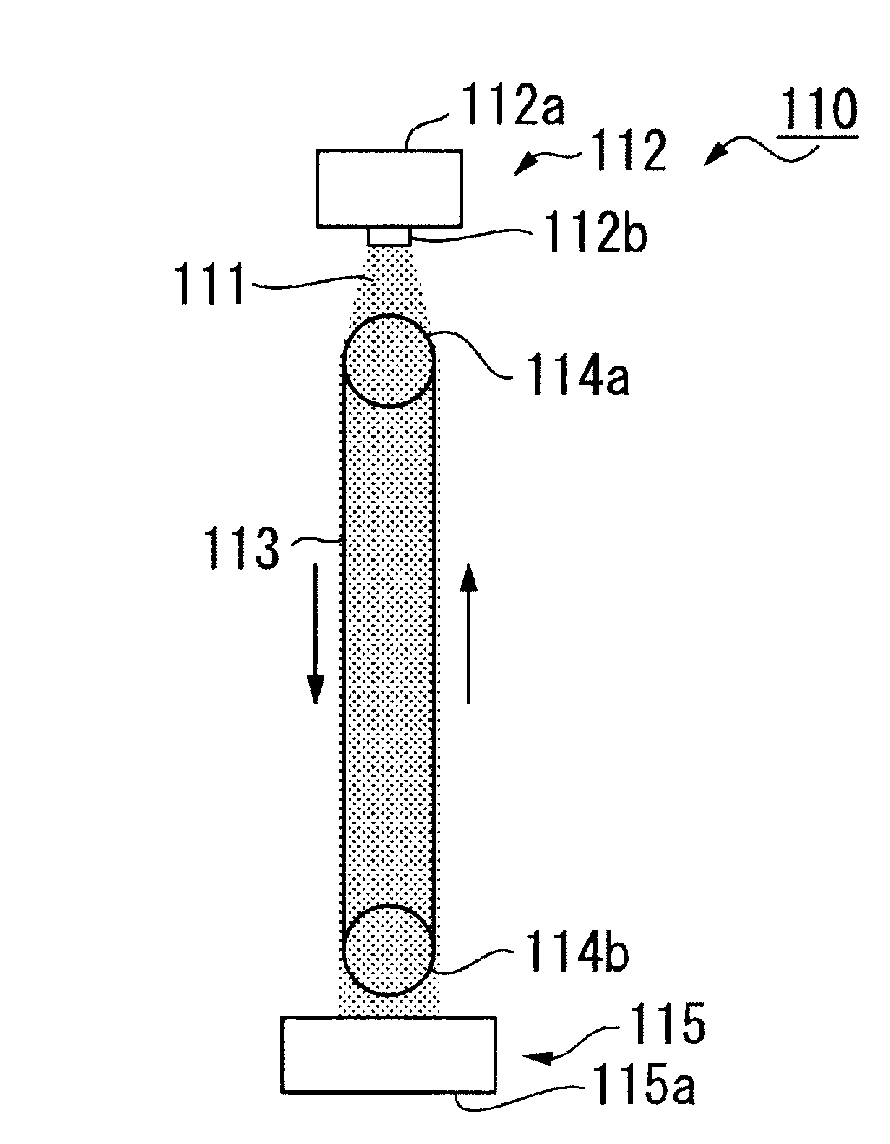

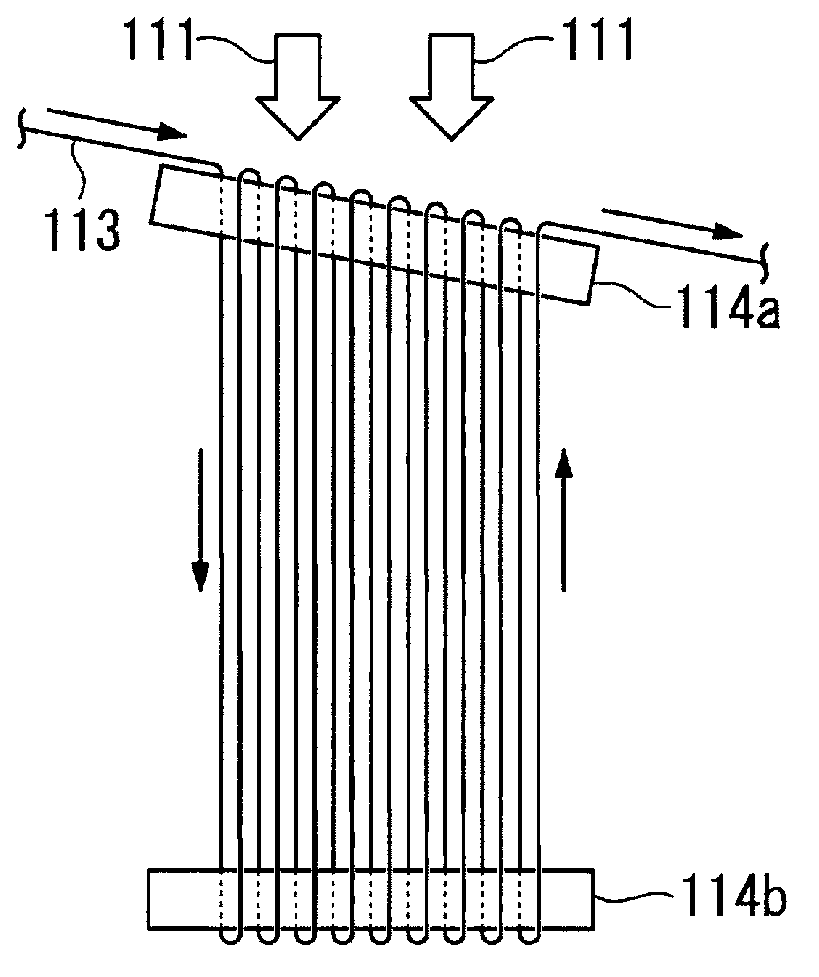

[0430] For the following Examples 2-4 and Comparative Example 1 figure 1 The device shown is cleaned.

[0431] The temperature of the cleaning solution in Examples 2 to 4 was adjusted to 80° C. with a heat exchanger, and circulated by a pump. In addition, by supplying or increasing pure water at 2 L / min, a part of the clea...

Embodiment 2

[0437] The porous membrane after the coagulation step was formed in the same manner as in Test Example 1.

[0438] Next, the obtained porous membrane was run at a speed of 10 m / min to perform cleaning treatment. The porous membrane after the treatment is cut into a length of 50 cm, and the mass (W 1 ), quality (W 2 ), quality (W 3 ) and residual solvent concentration (C 0 ). In addition, the residual solvent concentration (C 0 ) is the residual solvent concentration in the porous membrane before the cleaning treatment (residence time in the cleaning solution: 0 seconds).

[0439] Next, the washed porous membrane with a measured mass was immersed in 50 mL of pure water (normal temperature) for half a day to diffuse and extract DMAc remaining in the porous membrane into the pure water (extraction treatment). Collect the pure water after the extraction process, according to the measured value and the dilution ratio (according to the quality of the pure water used in the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com