Solar cell module and method of manufacturing solar cell module

A technology of solar cells and manufacturing methods, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of reduced connection reliability of solar cell units, flux residues, etc., and achieves inhibition of contact corrosion of dissimilar metals, prevention of reduction in power generation efficiency, Effect of improving connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

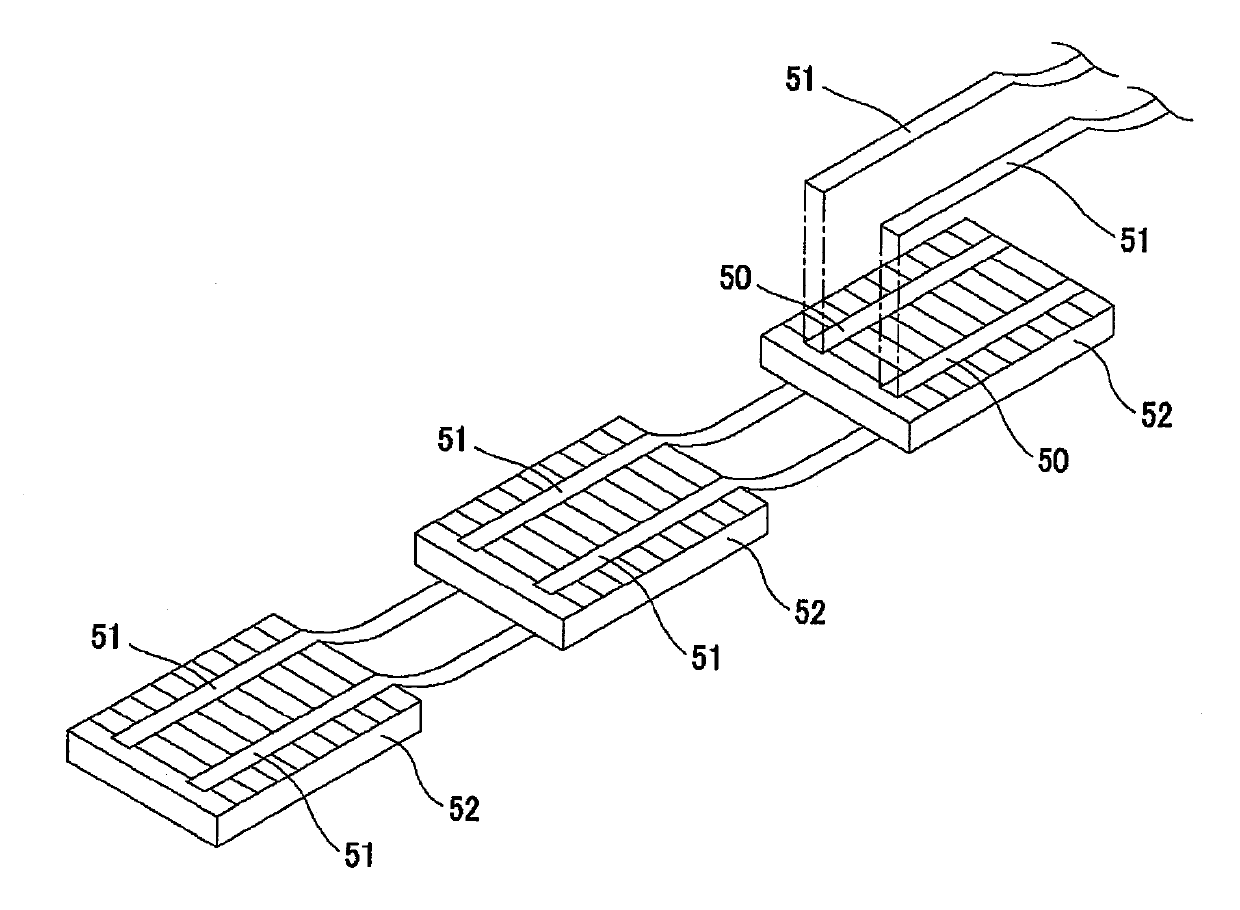

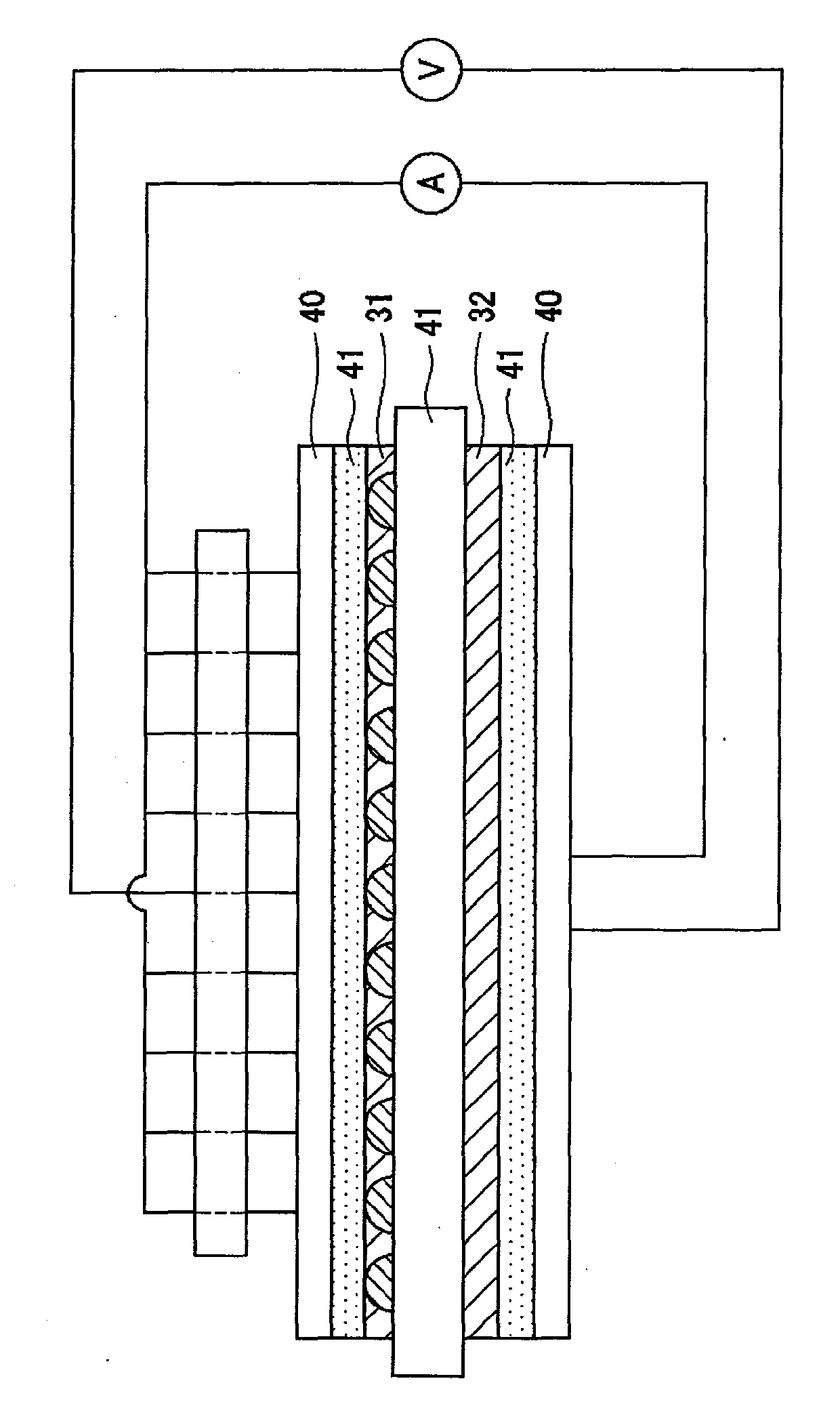

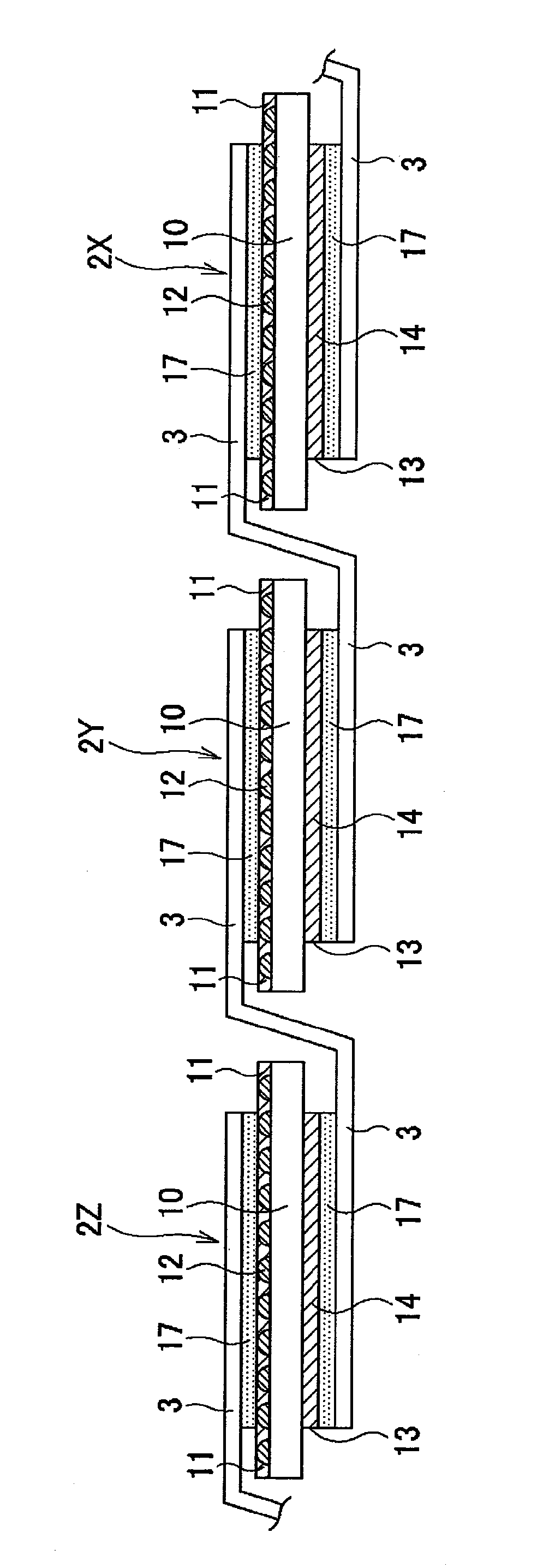

[0077] Next, examples of the present invention will be described. Such as Image 6 As shown, in this example, samples 41 of a plurality of types of conductive adhesive films in which the materials of the conductive particles contained in the binder resin were different were prepared, and samples 41 in which the base material and the conductor of the connection surface were different were prepared. Samples of 40 types of joint wires. Then, two samples 40 of these tab lines were thermally pressed on each of the front electrodes 31 and the back electrodes 32 of the photoelectric conversion element 30 formed with the front electrodes 31 and the back electrodes 32 through the sample 41 of the conductive adhesive film. bonding. All the hot press conditions were 180° C., 10 sec, and 2 MPa.

[0078] Regarding the composition of sample 41 of the conductive adhesive film, a mixture of

[0079] Phenoxy resin (YP-50: manufactured by Nippon Steel Chemical Co., Ltd.): 20 parts by mass; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com