Baked wheat cake wrapper forming machine and processing method

A technology of forming machine and dough, which is applied in the fields of dough processing, baking, food science, etc., can solve the problems of unfavorable automation and large-scale production, high labor intensity, troublesome production, etc., achieve uniform size, reduce labor intensity, and cut The effect of less material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

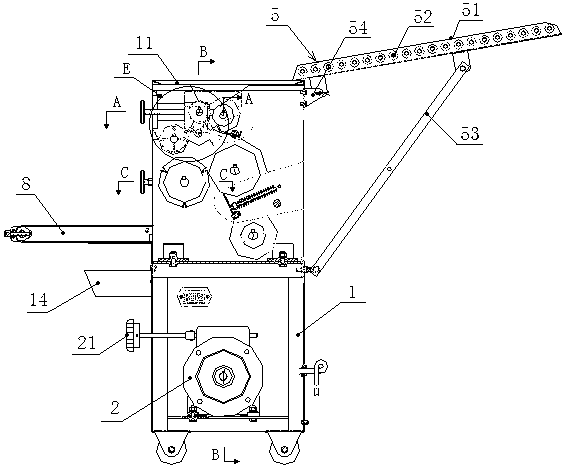

[0024] figure 1 Shown is the structure diagram of the present invention.

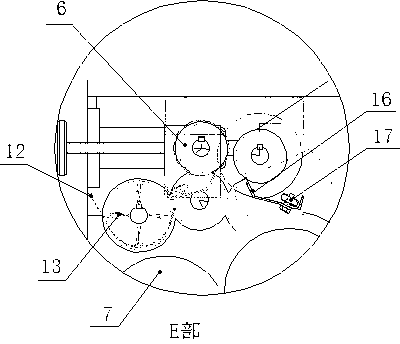

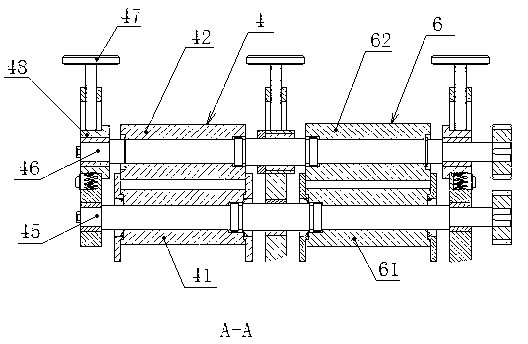

[0025] The present invention comprises a frame 1 and a speed-regulating reducer 2, the speed-regulating reducer 2 is arranged on the lower part of the frame 1, and the upper part of the frame 1 is provided with a pressing part 4 and a shaping part 6 fixed on the coaxial, pressing The bottom of the surface part 4 is provided with a connecting plate 18, and the outside of the upper frame of the shaping part 6 is provided with a dustpan assembly 5, the bottom of the shaping part 6 is provided with a forming part 7, and the bottom of the forming part 7 is provided with a conveyor belt assembly. 8. Below the conveyor belt combination 8, there is a residual material receiving tray 14. The pressing surface part 4, the shaping part 6, the forming part 7 and the conveyor belt combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com