Method for high-accuracy turning of outer circles or inner holes of shaft-type workpieces on numerical control machine tool

A shaft workpiece, CNC machine tool technology, applied in turning equipment, turning equipment, manufacturing tools and other directions, can solve the problems of input manpower, material resources increase, manufacturing cost increase, etc., to achieve good surface quality, reduce surface roughness value, easy-to-achieve effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

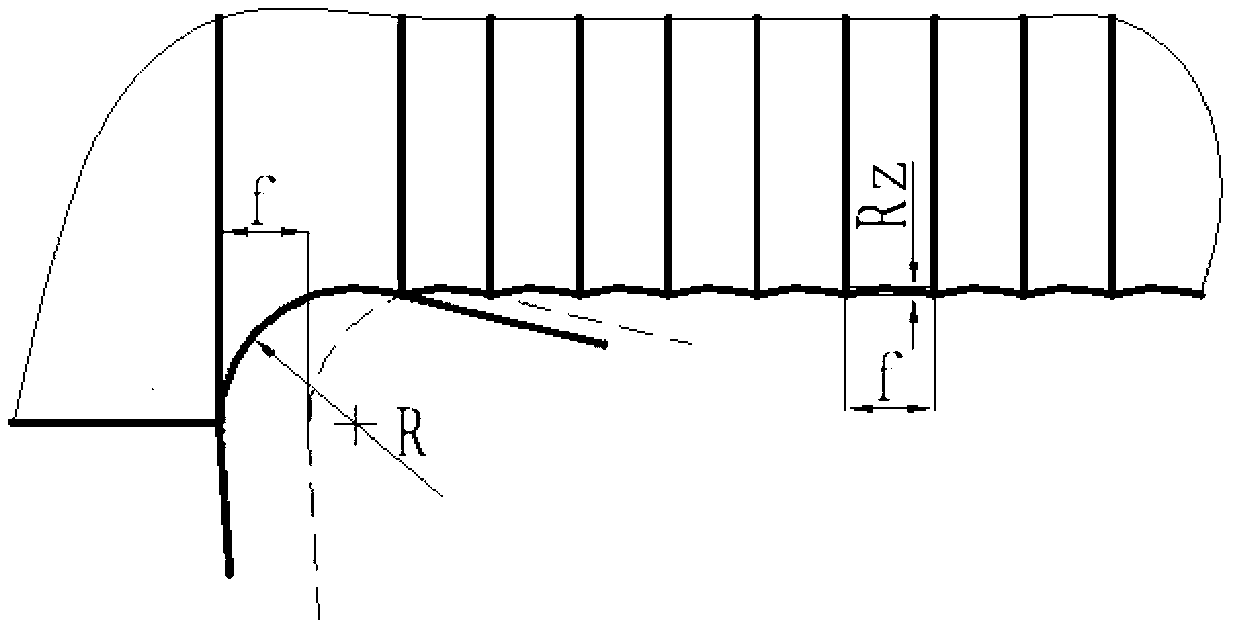

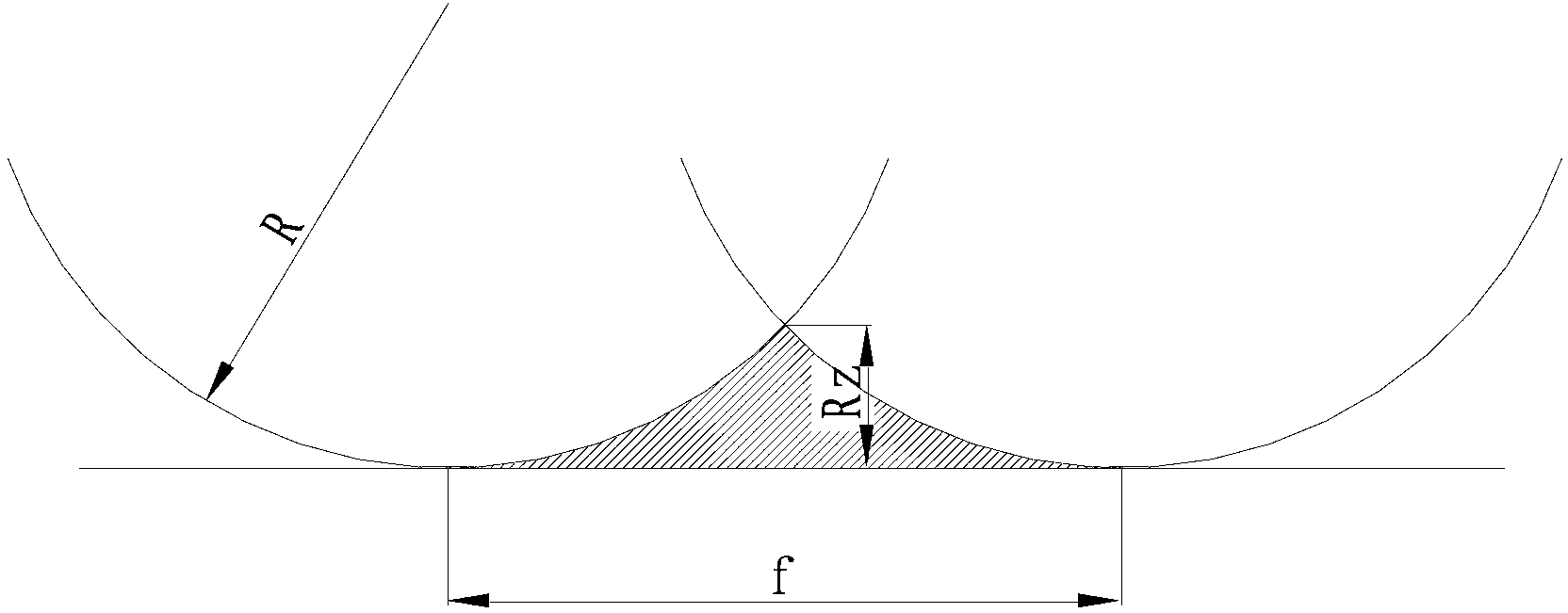

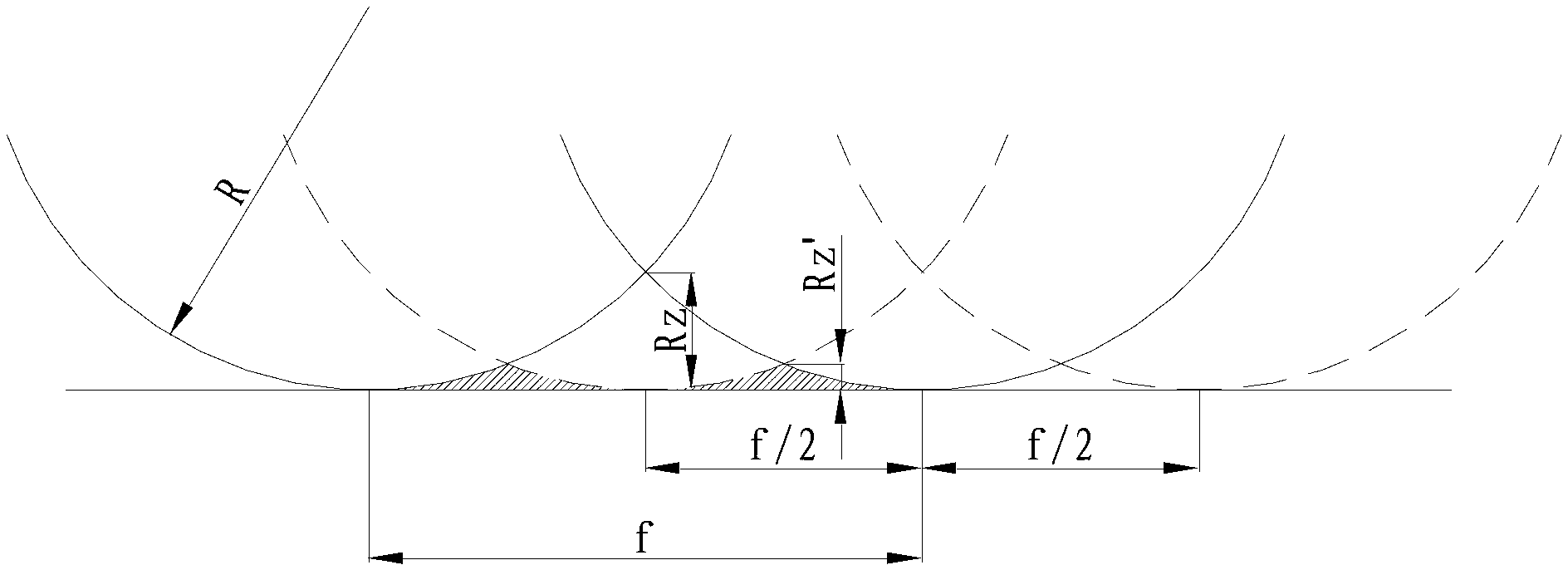

[0032] Such as Figure 2-5 As shown, the present invention is a high-precision turning method for the outer circle or inner hole of a shaft workpiece on a numerically controlled machine tool, comprising the following specific steps:

[0033] First, the shaft workpiece is clamped on the CNC machine tool; in this specific embodiment, the spindle of the CNC machine tool has an angular positioning function. The present invention can also be used on a numerically controlled machine tool without a spindle angle positioning function. At this time, manual auxiliary positioning is used to realize this high-precision turning method.

[0034] Initial finish turning: use the turning tool whose cutting parameters are the cutting depth ap and the feed rate f, the initial angular position of the orientation spindle is 0°, start from the end of the outer circle or the inner hole, and align the outer circle or the shaft workpiece along the axial direction Turning is performed on the inner hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com