Full-automatic internal polishing machine for circular elbow pipes

An internal polishing and polishing machine technology, which is applied in the field of polishing machines, can solve problems such as harsh processing environment, uneven polishing, and a lot of dust, and achieve reliable polishing quality, high polishing efficiency, and labor-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

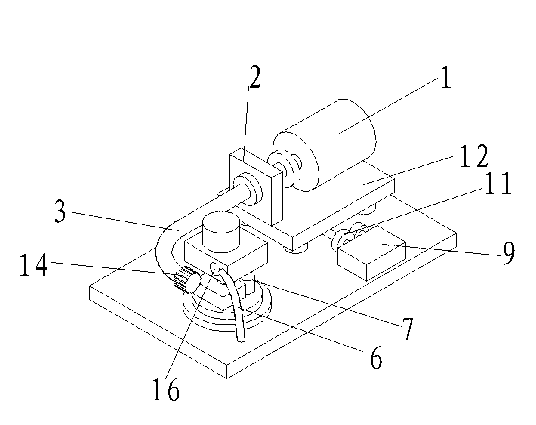

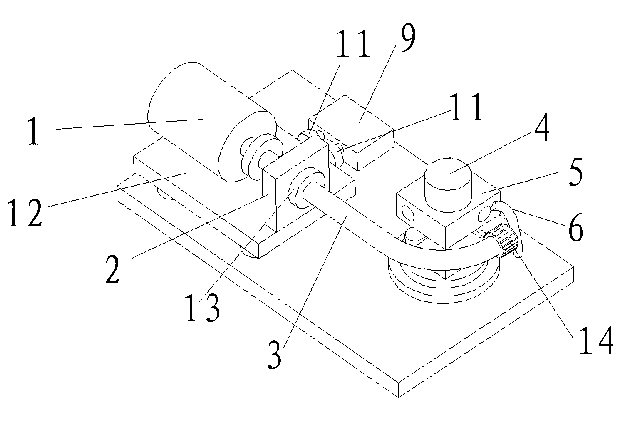

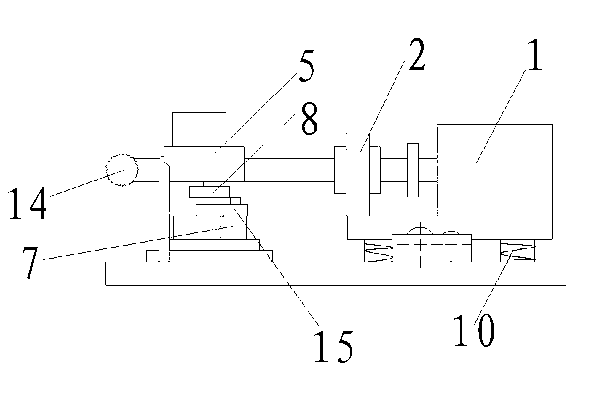

[0017] The present invention will be further elaborated below in conjunction with the accompanying drawings.

[0018] A full-automatic elbow circular tube internal polishing machine according to the present invention includes: a main motor 1 mounted on a motor plate 12, an inner polishing shaft 3, a polishing sandpaper head 14 placed at the end of the inner polishing shaft 3, an elbow The mold 5 is characterized in that: the main motor 1 is connected to the inner polishing shaft 3, the inner polishing shaft 3 is sleeved in the bearing seat 13, and is supported and fixed by the bearing bracket 2, and four springs are evenly distributed under the motor plate 12 10. It is used for buffering in the working process. The polishing sandpaper head 14 corresponds to the elbow mold 5. There is an arc-shaped mold hole 16 in the elbow mold 5, and a water pipe 6 is installed next to the mold hole 16.

[0019] The upper device of the elbow mold 5 has a cylinder 4, which is used to control t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com