Wrist joint structure of underwater mechanical arm

A technology of underwater manipulator and wrist joint, which is applied in the field of wrist joint structure, can solve the problems of large size and influence on the movement of underwater manipulator, and achieve the effects of light weight, simple structure, and low manufacturing and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the drawings.

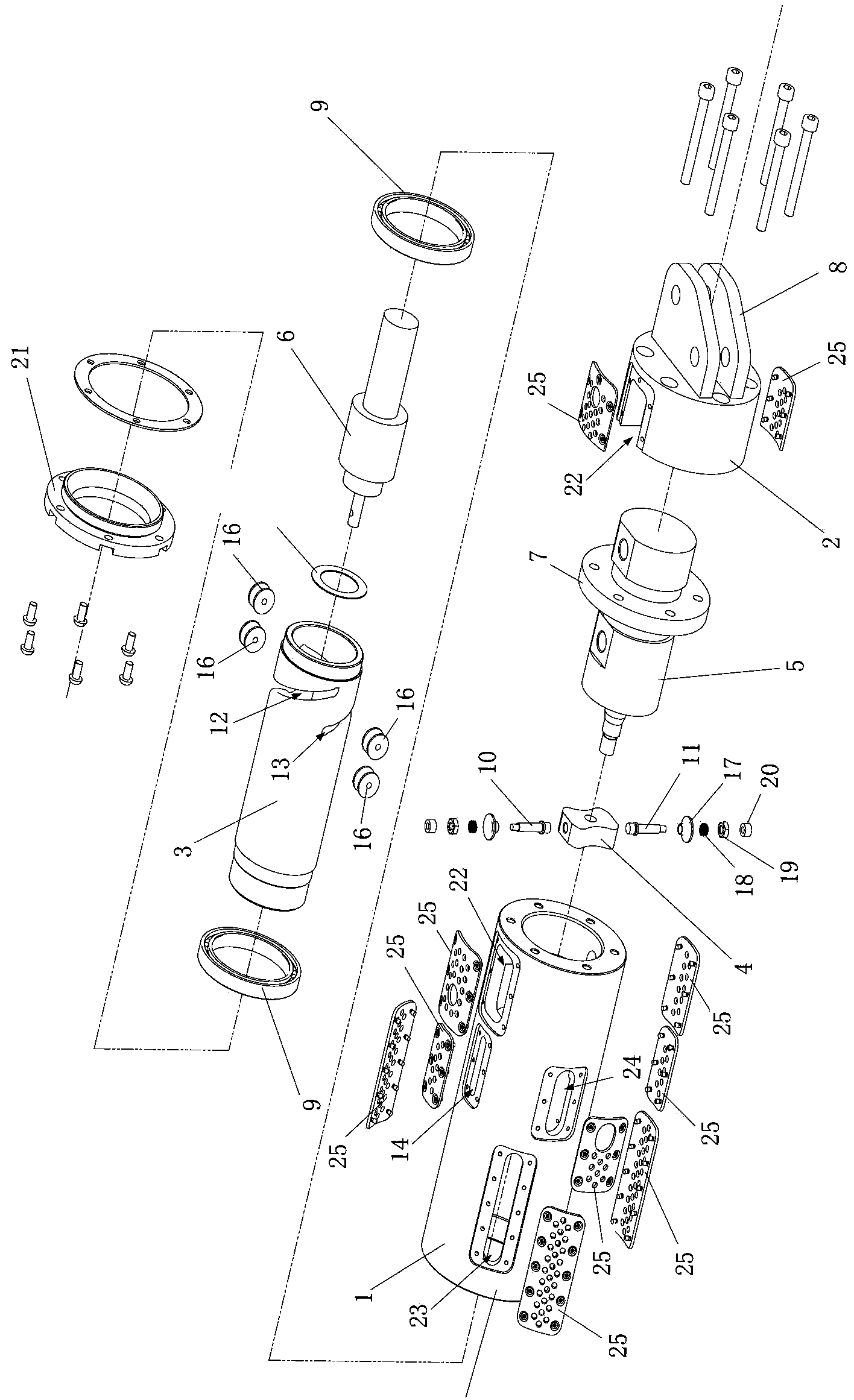

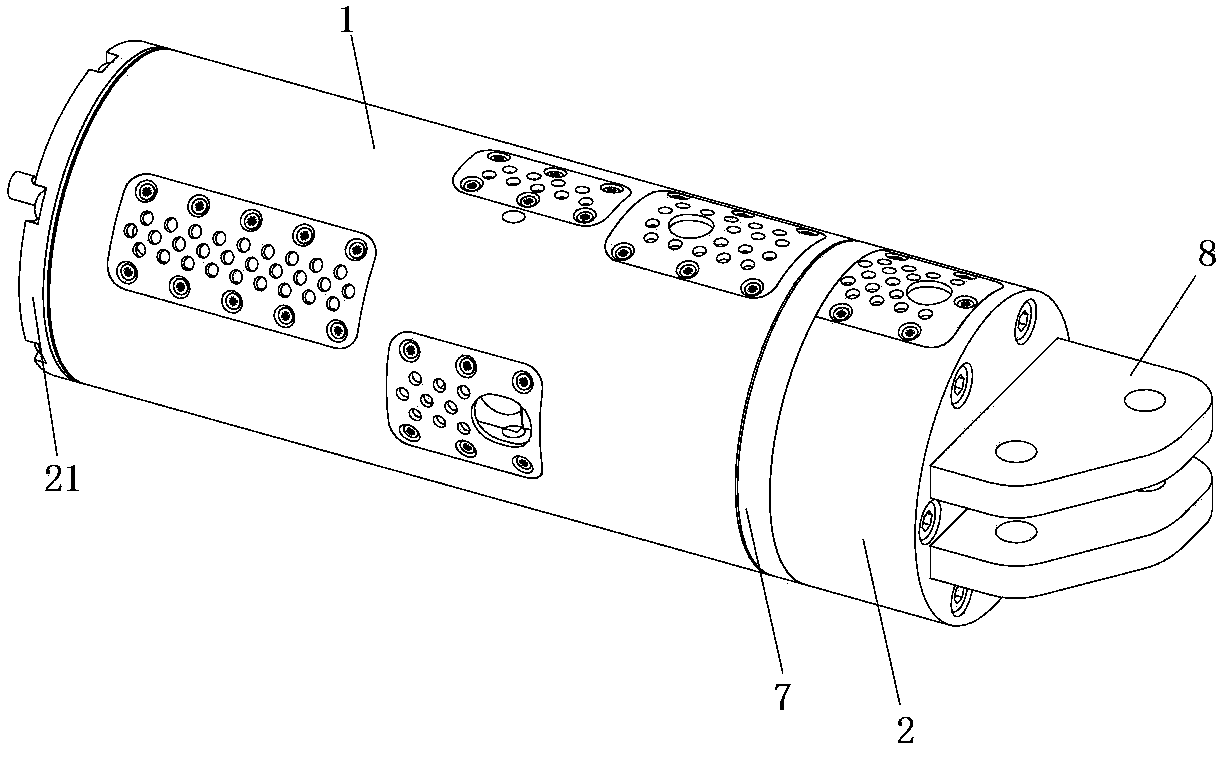

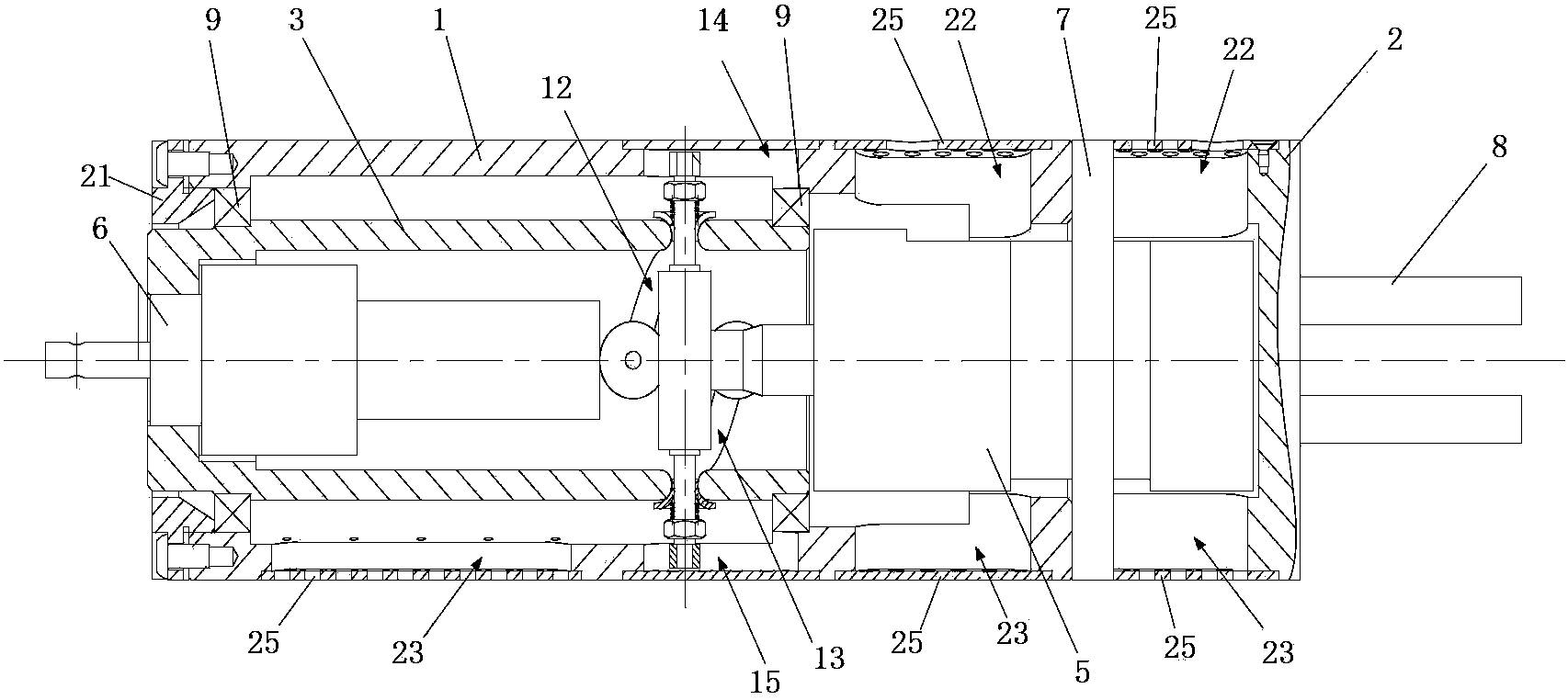

[0034] The wrist joint structure of the present invention includes an outer cylinder 1, a tail cover 2, a cam cylinder 3, a pin plate 4, a first hydraulic cylinder 5 and a second hydraulic cylinder 6, such as figure 1 , figure 2 , image 3 Shown.

[0035] Wherein, the rear end of the outer cylinder 1 is fixedly connected to the tail cover 2 through the flange 7 provided in the axial direction of the first hydraulic cylinder 5, thereby forming an integral cylindrical wrist joint shell; thereby fixing the first hydraulic cylinder 5 to the wrist joint Inside the housing, and the piston rod of the first hydraulic cylinder 5 faces the front end of the cam barrel 3. A hinge frame 8 is designed on the end surface of the tail cover 2 to realize the connection between the wrist joint structure of the present invention and the joint of the underwater robot arm. A cam cylinder 3 is coaxially arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com