Modular hydraulic-drive four-leg robot with variable leg shape structures

A quadruped robot, modular technology, applied in motor vehicles, transportation and packaging, etc., can solve the problems of increasing control difficulty, dynamic attitude adjustment difficulty, changing assembly direction, weak joints, etc. Good dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

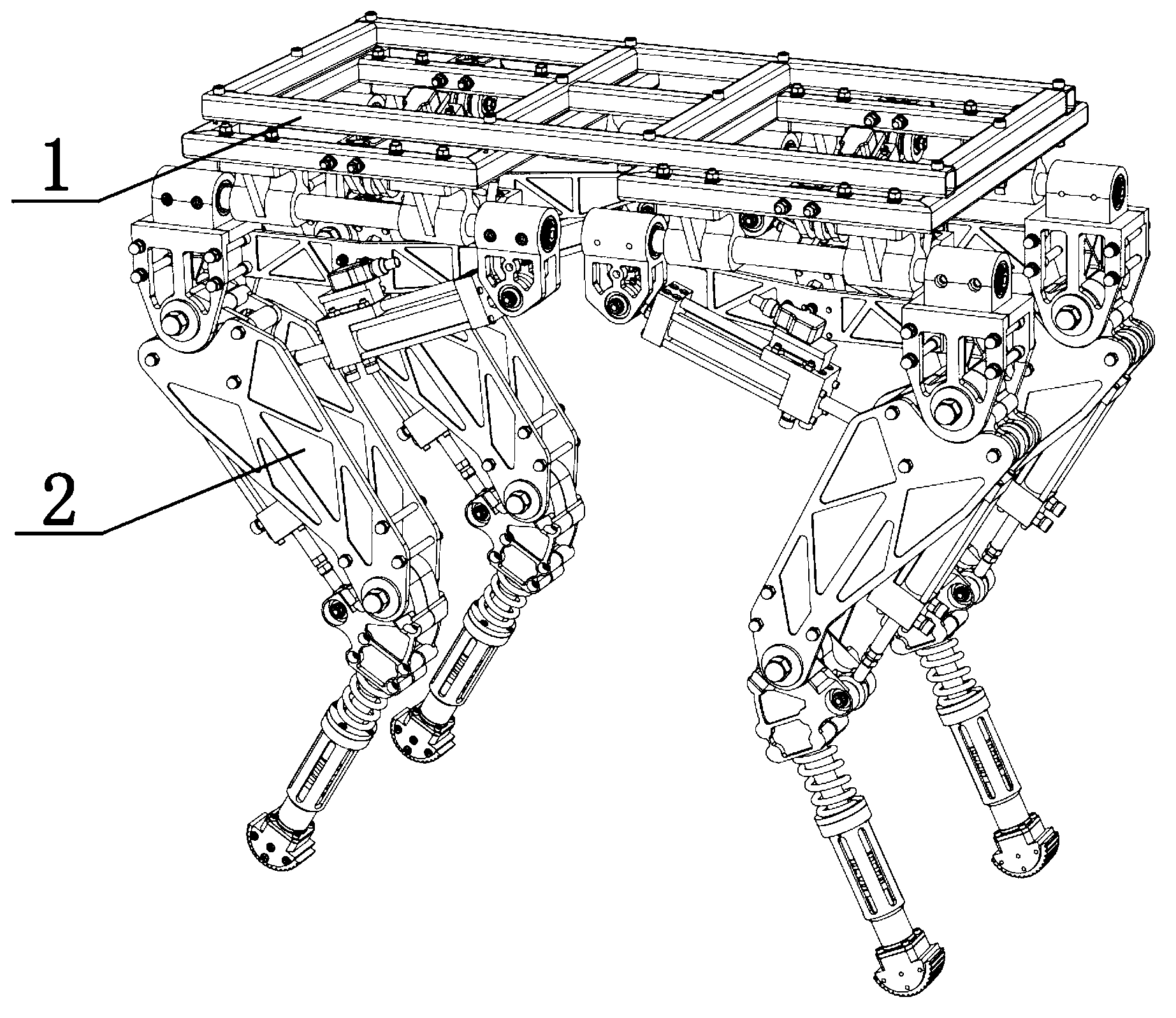

[0029] Such as figure 1 As shown, the robot includes a body frame 1 and two double-leg modules 2, and the two double-leg modules 2 are installed in the front knee and rear elbow with fasteners such as bolts to form an inwardly curved robot.

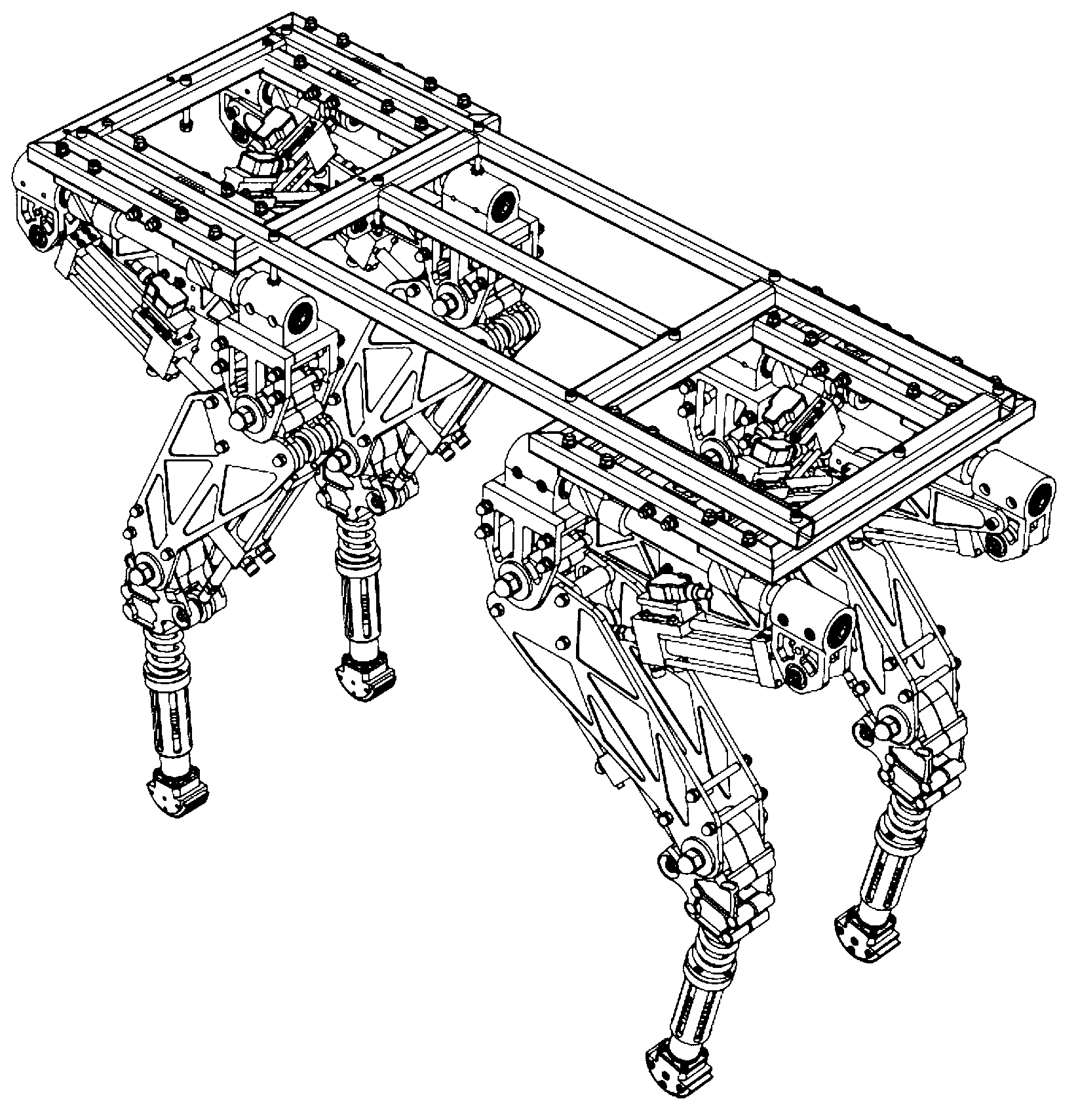

[0030] Such as figure 2 As shown, two double-leg modules 2 are installed according to the front elbow and the back knee formula to be an outward bending robot.

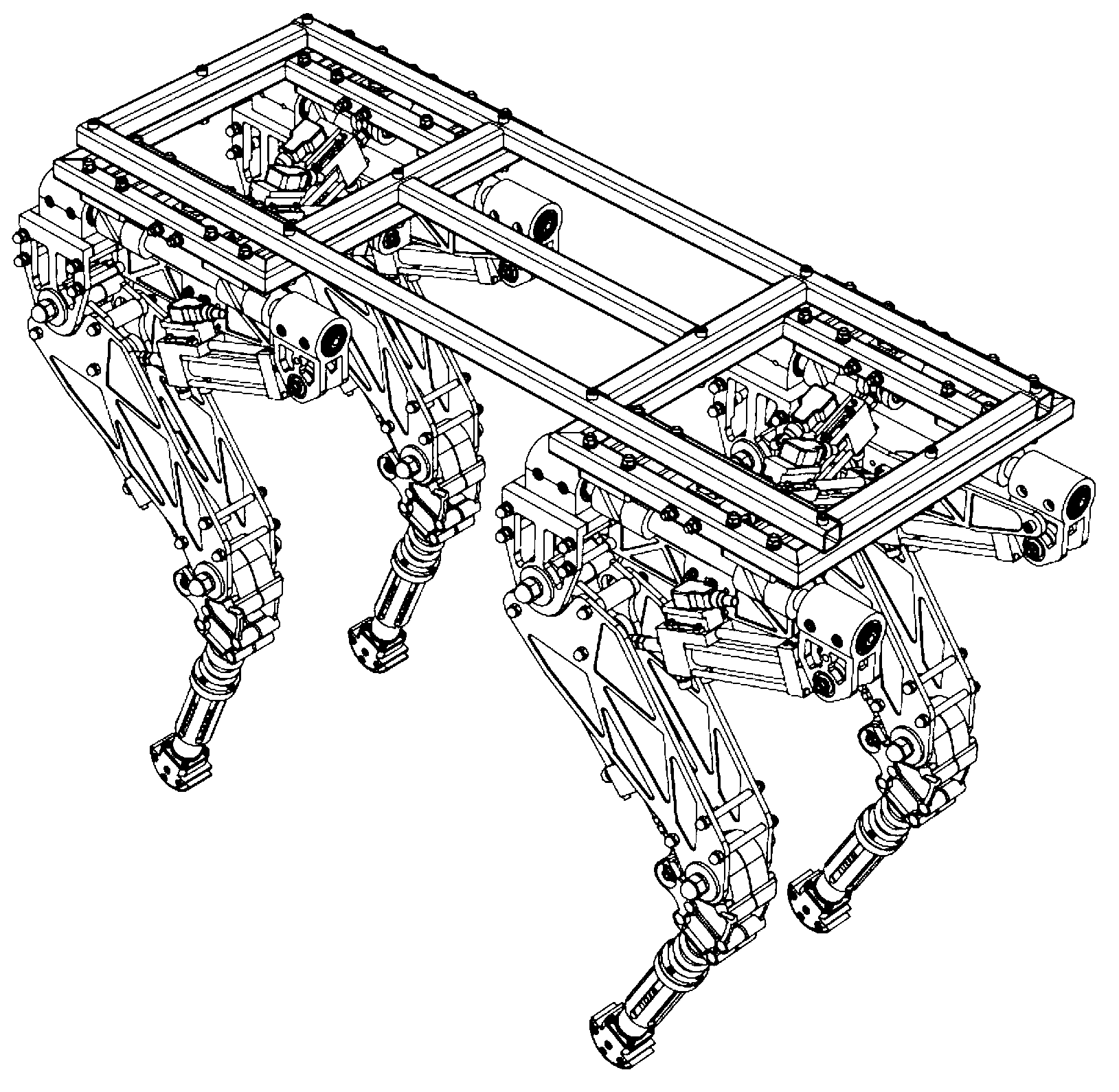

[0031] Such as image 3 As shown, the two double-leg modules 2 are installed in a full-elbow or full-knee type to form a full-elbow or full-knee robot. The connection method is simple and reliable, and it can be quickly disassembled to realize the conversion of different leg configurations.

[0032] Such as Figure 4 As shown, the double-leg module 2 includes a double-leg connection frame 3 and two single-leg modules 4 .

[0033] Such as Figure 5As shown, the sing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com