Method for removing organic pollutants in water through electrochemical cathode catalytic ozonation

A technology of organic pollutants and cathodic catalysis, applied in the field of water treatment, can solve the problems of great impact on water quality, catalyst loss, high energy consumption, etc., and achieve the effect of improved removal rate, low cost and high treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment one: This embodiment is a method for removing organic pollutants in water by electrochemical cathode catalytic ozonation oxidation. Use ozone gas aeration method or ozone saturated solution method to add ozone, and treat it for 10s~20min at the dosage of ozone at 0.1mg / mgTOC~100mg / mgTOC, and then treat at the dosage of ozone at 0.1mg / mgTOC~ 100mg / mgTOC and the cathode electrode voltage is +2.0V~-2.5V and treated for 2min~40min, that is, the water treatment of the organic matter pollution to be treated is completed.

[0015] In this embodiment, the electrochemical cathode catalytic ozone oxidation contact chamber is used to oxidize and degrade the organic matter under the background components of the water body, such as natural humic acid, which rapidly consumes ozone and generates free radicals at an ozone dosage of 0.1 mg / mgTOC to 100 mg / mgTOC, and then The process of removing organic pollutants in water is completed when the dosage of ozone is 0.1m...

specific Embodiment approach 2

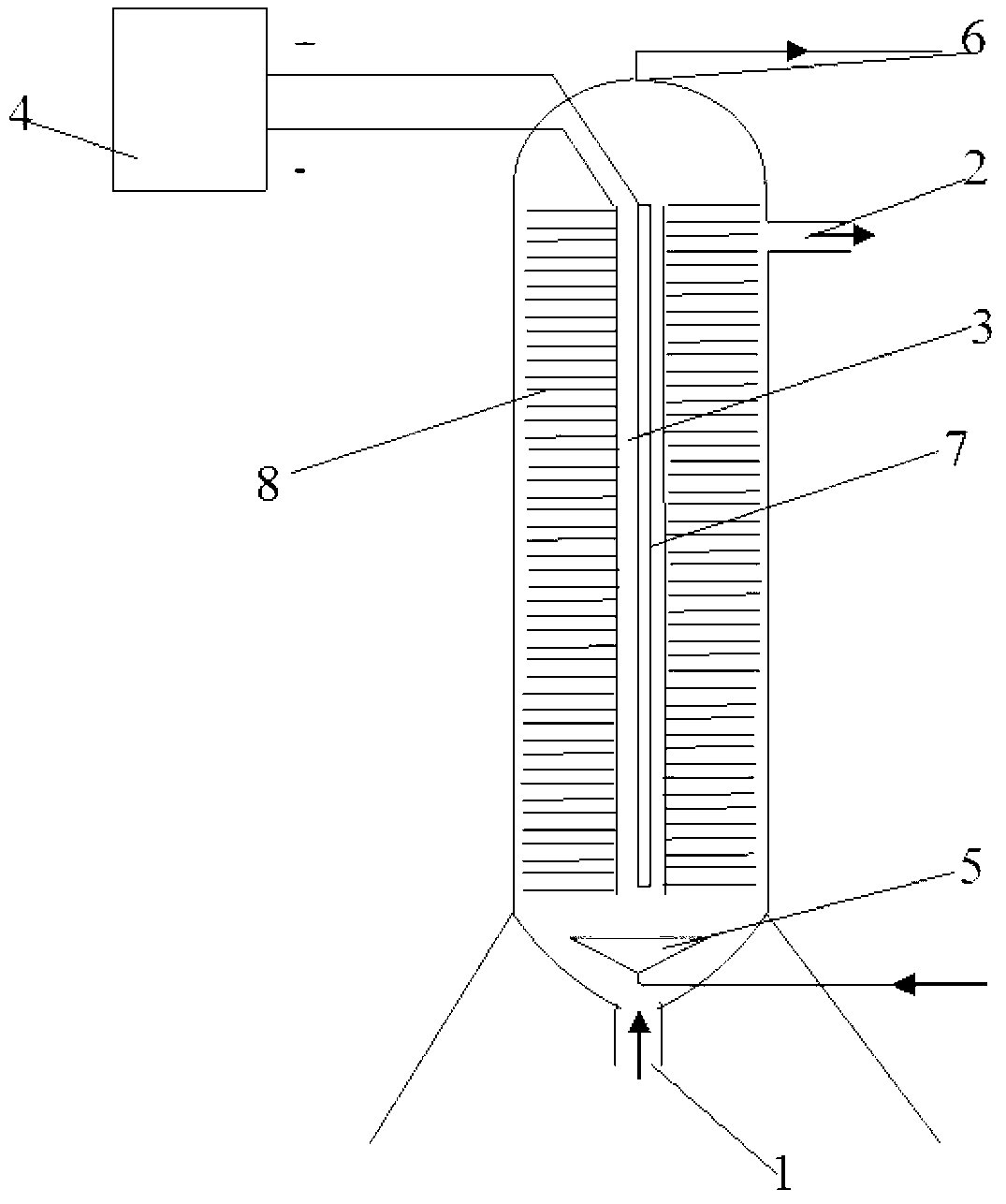

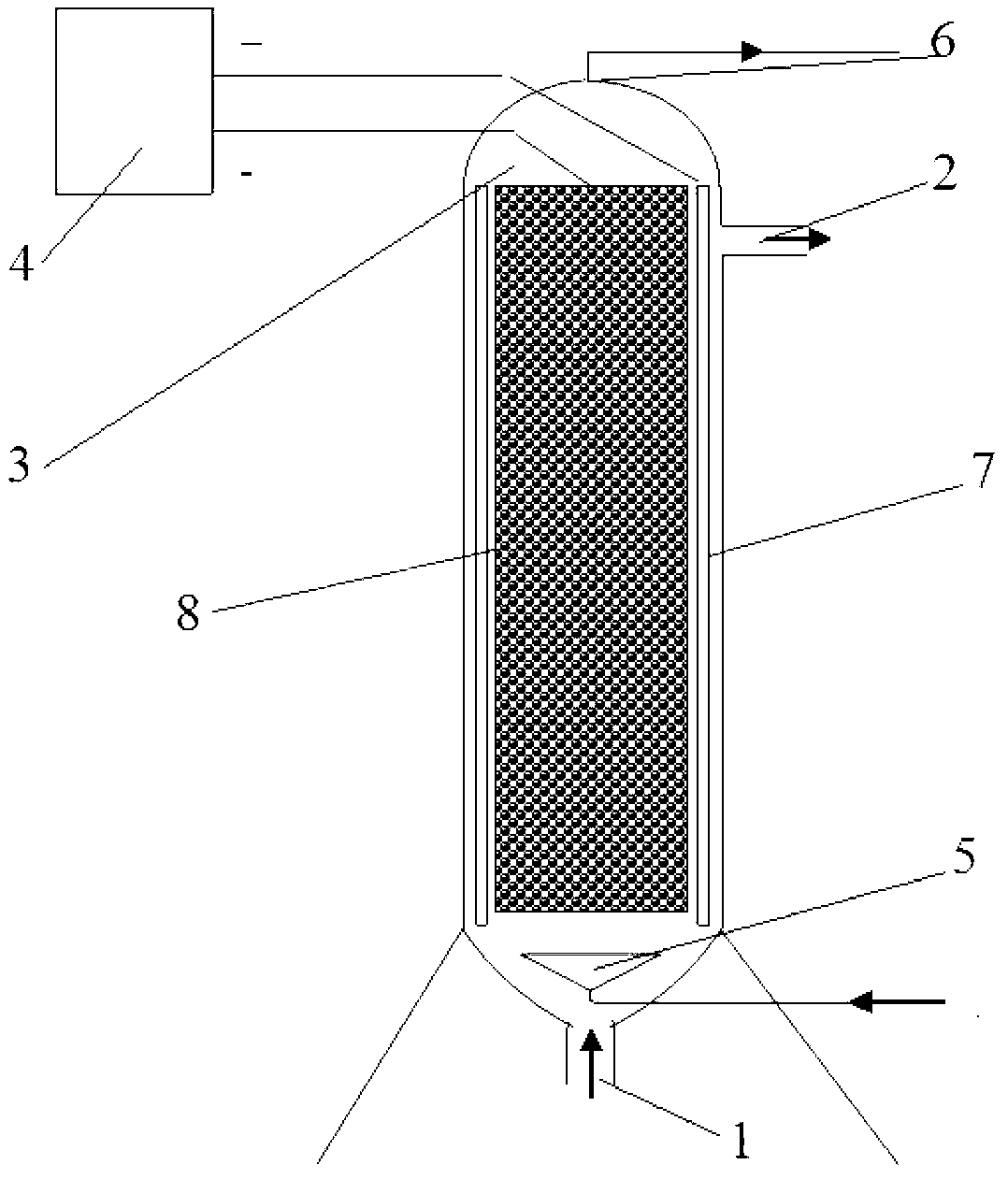

[0017] Specific implementation mode two: combination figure 1 The difference between this embodiment and specific embodiment 1 is: the electrochemical cathode catalytic ozone oxidation contact chamber includes a water inlet 1, a water outlet 2, an ozone contact chamber 3, a constant voltage power supply 4, an ozone inlet device 5, Ozone gas outlet 6, anode 7 and cathode 8, water inlet 1 is set at the center of the bottom of ozone contact chamber 3, water outlet 2 is set at the upper part of the side wall of ozone contact chamber 3, and ozone gas outlet 6 is set at the center of the top of ozone contact chamber 3 The anode 7 and the cathode 8 are arranged in the ozone contact chamber 3 in the form that the anode 7 is inside and the cathode 8 is outside, the ozone inlet device 5 is arranged in the ozone contact chamber 3, the anode 7 and the cathode 8 are respectively connected with the constant voltage power supply Positive and negative connections. Others are the same as the ...

specific Embodiment approach 3

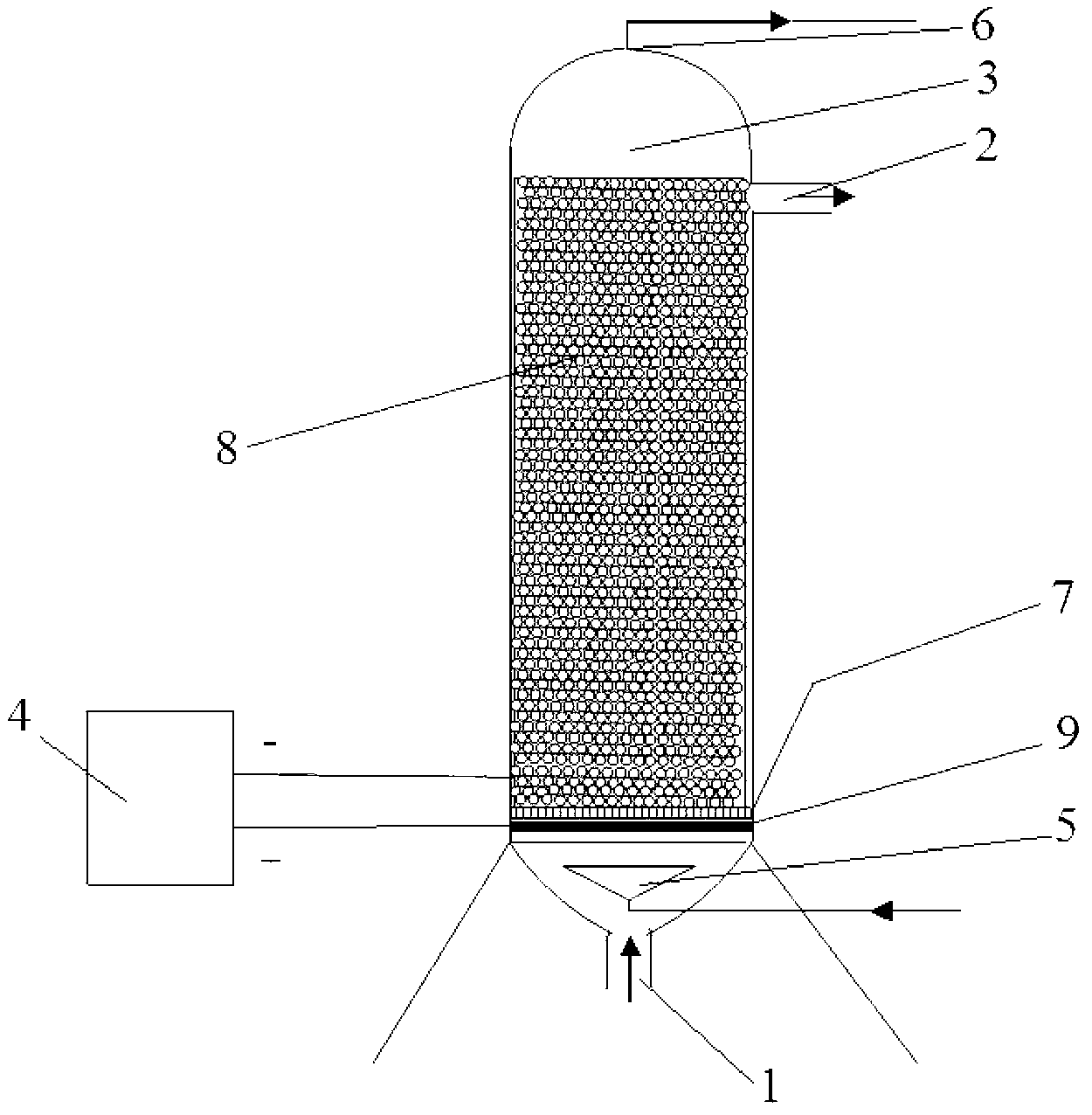

[0020] Specific implementation mode three: combination figure 2 The difference between this embodiment and specific embodiment 1 is: the electrochemical cathode catalytic ozone oxidation contact chamber includes a water inlet 1, a water outlet 2, an ozone contact chamber 3, a constant voltage power supply 4, an ozone inlet device 5, Ozone gas outlet 6, anode 7, cathode 8 and porous separator 9, water inlet 1 is set at the bottom center of ozone contact chamber 3, water outlet 2 is set at the upper part of the side wall of ozone contact chamber 3, and at the center of ozone contact chamber 3 top The ozone gas outlet 6 is set, and the anode 7 and the cathode 8 are arranged in the ozone contact chamber 3 in the form of the anode 7 on the bottom and the cathode 8 on the top, and the porous separator 9 is arranged in the ozone contact chamber 3, between the anode 7 and the cathode 8 , The ozone inlet device 5 is arranged in the ozone contact chamber 3, and the anode 7 and the cath...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com