High-performance solid oxide electrolytic tank support

A technology of solid oxides and supports, applied in solid electrolyte fuel cells, fuel cells, fuel cell components, etc., can solve the problems of Ni particle agglomeration, reduction of three-phase interface area, performance attenuation of solid oxide electrolytic cells, etc. , to achieve the effects of strengthening the gas diffusion conditions, simplifying the operation, and increasing the interface area of the three-phase reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

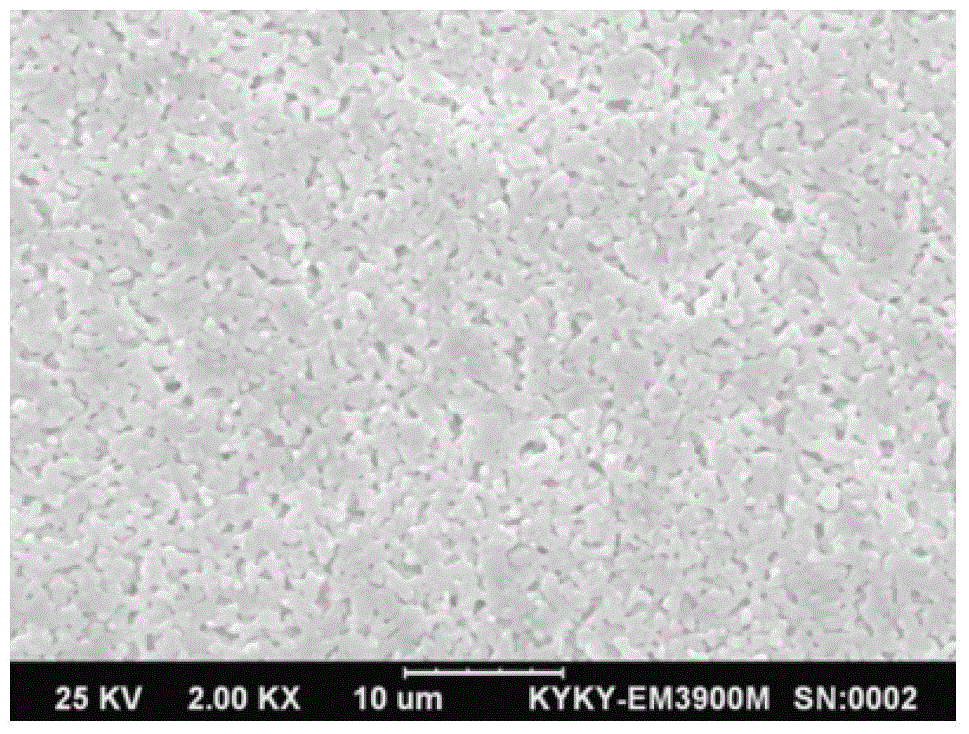

[0031] 1) Dissolve 2% ammonium polyacrylate dispersant (DURAMAX D-3019) in water to form a dispersion, adjust the pH to 9, add 8YSZ (TZ-8YS produced by Tosoh, 25vol% of water) powder, After stirring and ultrasonication, 5% binder (DURAMAX B-1000) in water quality was added, and ball milled for 2 hours. The average particle size of the 8YSZ powder is 0.258μm, and the specific surface is 6.271m 2 / g.

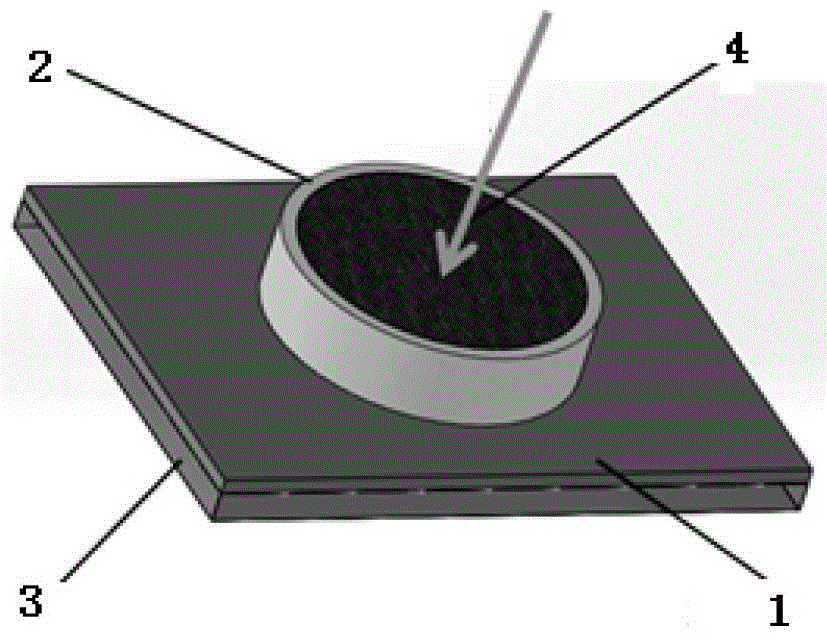

[0032] 2) Pouring. Use 704 waterproof silica gel to fix the polypropylene resin mold on the metal freezing plate to make a pouring mold, and pour the water-based slurry in step 1) into the above-mentioned mold.

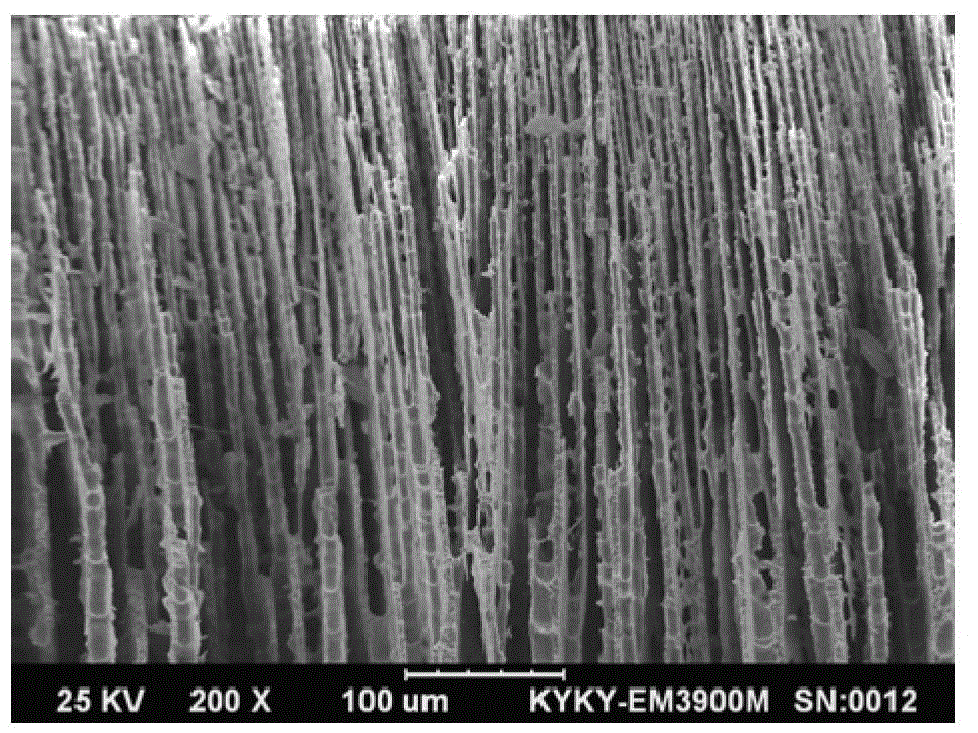

[0033] 3) Water oriented crystal growth. The low temperature and constant temperature stirring reaction bath (DHJF-8002 produced by Beijing Ruicheng Weiye Instrument Equipment Co., Ltd., the lowest temperature can reach -80°C) provides the cold source, and alcohol is used as the freezing medium, and the temperature is -60°C. Place the metal freezing plate in step 2, a...

Embodiment 2

[0038] 1) Dissolve 3% ammonium polyacrylate dispersant (DURAMAX D-3019) in water to form a dispersion, adjust the pH to 9, add 8YSZ (TZ-8YS produced by Tosoh, 30vol% based on water) powder body, stirred and ultrasonically added 5% binder (DURAMAX B-1000) in water quality, and ball milled for 2 hours. The average particle size of the 8YSZ powder is 0.258μm, and the specific surface is 6.271m 2 / g.

[0039] 2) Pouring. Use 704 waterproof silicone to fix the polypropylene resin mold on the metal freezing plate to make the pouring mold. Pour the water-based slurry in step 1 into the above mold.

[0040] 3) Water oriented crystal growth. The low temperature and constant temperature stirring reaction bath (DHJF-8002 produced by Beijing Ruicheng Weiye Instrument Equipment Co., Ltd., the lowest can reach -80°C) provides a cold source, and alcohol is used as a freezing medium, and the temperature is -40°C. Place the metal freezing plate in step 2, and freeze the slurry after 1 hour....

Embodiment 3

[0044] 1) Dissolve 3% ammonium polyacrylate dispersant (DURAMAX D-3019) in water to form a dispersion, adjust the pH to 9, add NiO-8YSZ (NiO and 8YSZ powder quality 55:45, alcohol wet Ball milled for 8 hours, dried to obtain; 30vol% based on water) powder, stirred and ultrasonically added with 5% water quality binder (DURAMAX B-1000), ball milled for 2 hours.

[0045] 2) Pouring. Use low temperature resistant waterproof silica gel (704 waterproof silica gel) to fix the polypropylene resin mold on the metal freezing plate to make the pouring mold. Pour the water-based slurry in step 1 into the above mold.

[0046] 3) Water oriented crystal growth. The low temperature and constant temperature stirring reaction bath (DHJF-8002 produced by Beijing Ruicheng Weiye Instrument Equipment Co., Ltd., the lowest can reach -80°C) provides a cold source, and alcohol is used as a freezing medium, and the temperature is -40°C. Place the metal freezing plate in step 2, and freeze the slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com