Classifying and recycling process for waste magnesia carbon bricks produced after use of steel tundish working linings as well as dry material and coating material for tundish

A technology of waste magnesia carbon bricks and working lining, which is applied to the removal of solid waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

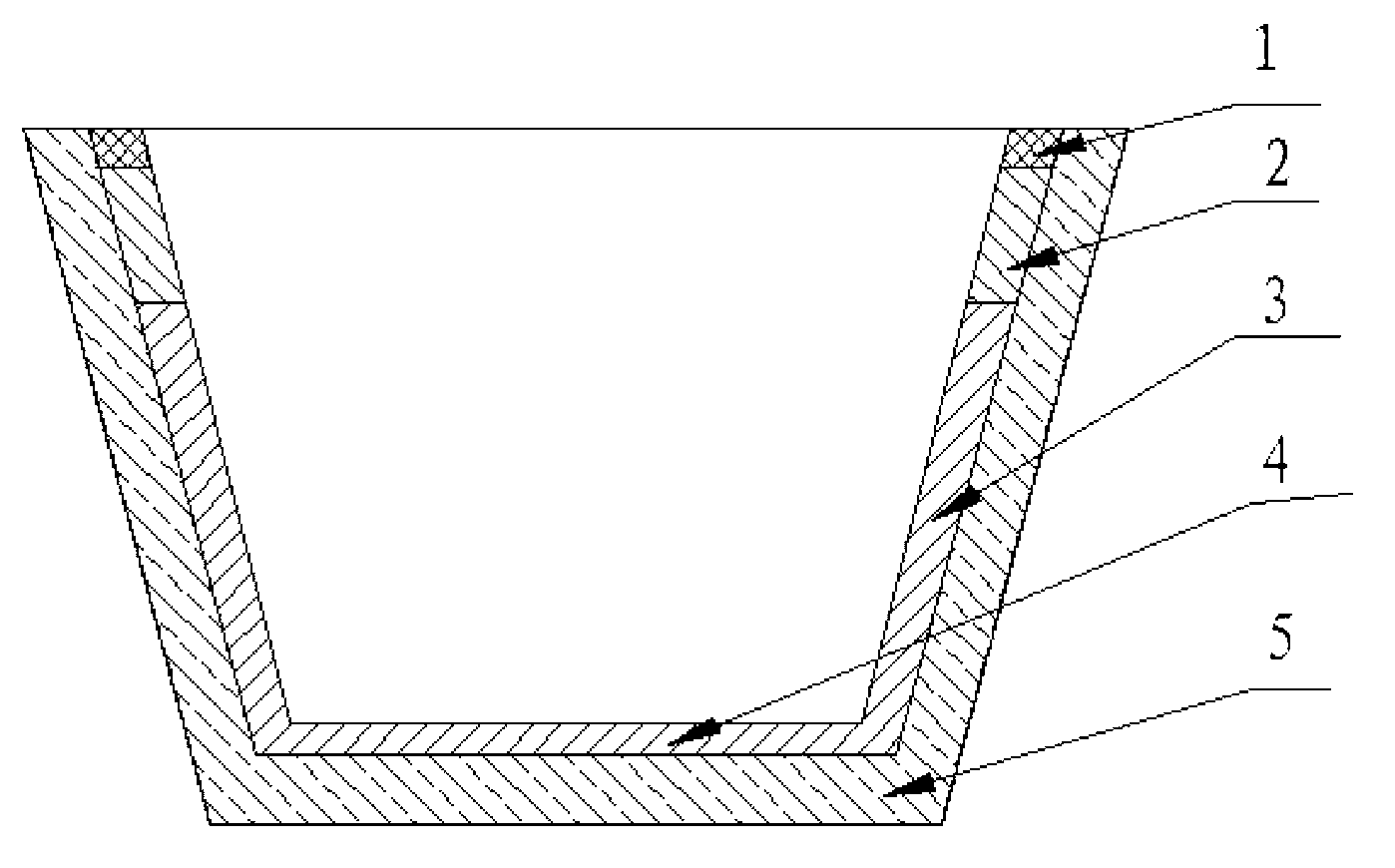

Image

Examples

Embodiment Construction

[0011] A tundish dry material and smear material using waste magnesia-carbon bricks as raw materials. The waste magnesia-carbon bricks raw materials are three particle grades obtained by cleaning, crushing and screening waste magnesia-carbon bricks after ladle lining Recycled materials: Grade A material: 3mm≦particle size<5mm, Grade B material: 1mm≦particle size<3mm, Grade C material: particle size<1mm;

[0012] The mass ratio composition of described tundish dry material is as follows:

[0013] A grade material 5~10%, B grade material 10~15%;

[0014] High-purity magnesia: 3mm≦grain size<5mm 8~15%,

[0015] 1mm≦grain size<3mm 10~15%,

[0016] 0.083mm

[0017] Fused magnesia: 6.5-8% fine powder of 0.074mm<grain size≦0.083mm,

[0018] Micropowder with particle size ≦0.047mm 8~10%;

[0019] 95 mid-range magnesia: 0.074mm<particle size≦0.083mm fine powder 2~4%,

[0020] Al-Mg spinel: particle size≦0.047mm fine powder 3~5%,

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com