UV curing coating for make-up copying of holographic patterns and use method of UV curing coating

A technology for curing coatings and coatings, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as poor adhesion, inconvenient operation, and poor alignment accuracy, and achieve convenient control, no seams, and low cost cheap effect

Active Publication Date: 2015-06-24

湖北华工图像技术开发有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Taking advantage of the good adhesion of some types of UV-curable coatings to plastic substrates and poor adhesion to metals (such as nickel plates), UV-curable coatings have been applied to holographic pattern transfer technology in recent years, as proposed in Chinese patent No. 97114329: "A laser holographic image transfer technology and its application" is to use UV-curable coatings as a medium to transfer laser holographic patterns; for UV imposition work that requires repeated splicing of multiple unit plates, the above-mentioned method will have poor alignment accuracy and operation Inconvenience and other issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1~3

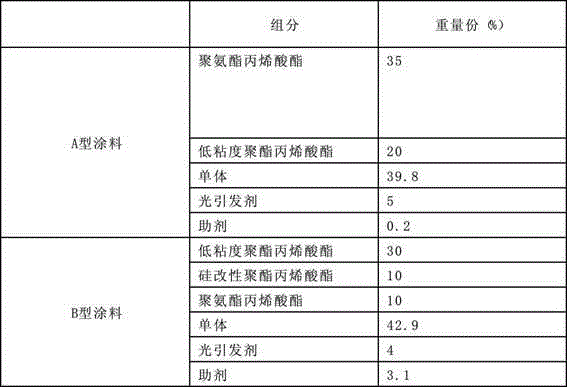

[0055] Embodiment 1~3, according to the formula preparation UV curing coating of following table:

Embodiment 1

[0056] The formula table of embodiment 1 Table 1

[0057]

Embodiment 2

[0058] The formula table of embodiment 2 Table 2

[0059]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

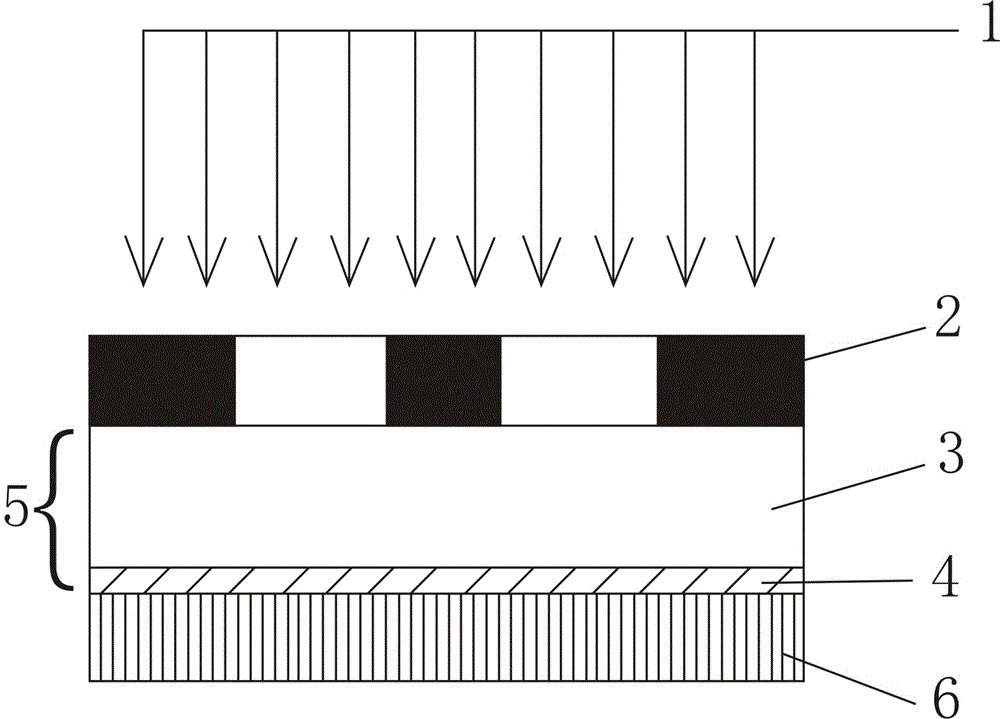

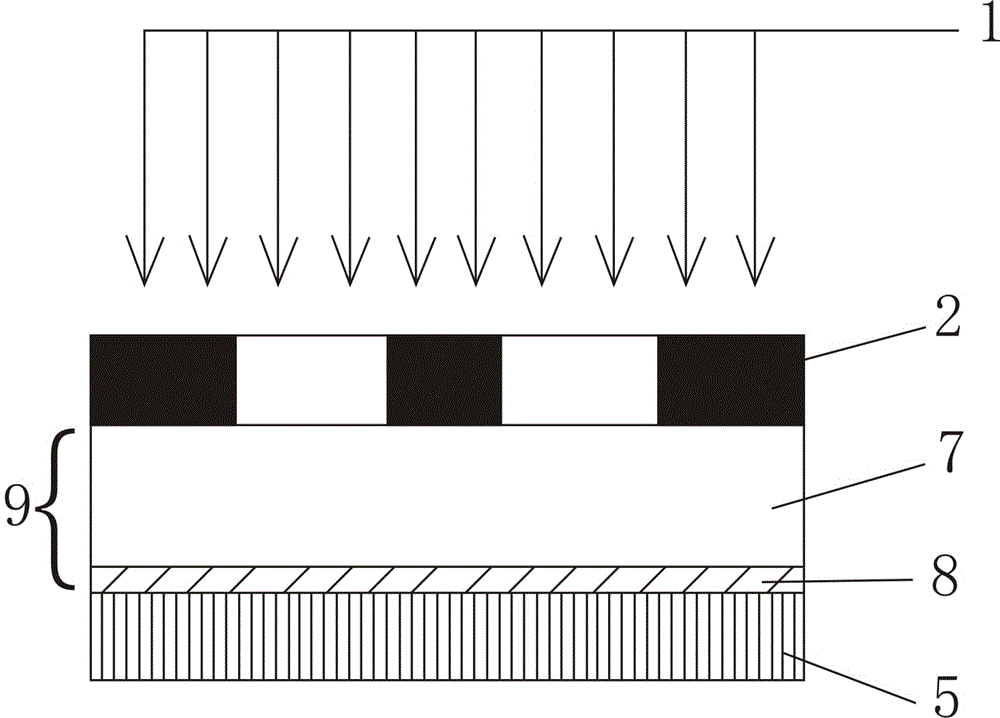

The invention relates to a UV coating for UV make-up copying of holographic patterns and a use method of the UV coating. The UV coating comprises a B-type coating and an A-type coating. The B-type coating comprises low-viscosity polyester acrylate, silicone-modified polyester acrylate, a polyurethane acrylate, monomers, auxiliaries and photoinitiators. The A-type coating comprises a polyurethane acrylate, the low-viscosity polyester acrylate, the monomers, auxiliaries and the photoinitiators. The B-type coating is added drop by drop between a holographic nickel plate and a transparent PET substrate, then a transparent holographic film plate is obtained by processing; then the A-type coating is added drop by drop between the transparent holographic film plate and the transparent PET substrate, a transparent holographic plate is copied out by processing; a transparent holographic large plate is obtained through repeated operation; a broad-width holographic dedicated mother plate is obtained through metallization processing on a coating curing layer of the transparent holographic large plate. The UV coating has a good adhesion on the plastic substrate, a bad adhesion on the holographic nickel plate, scratch resistance, and a good solvent resistance, and is benefit for completely copying and transferring of holographic patterns on the nickel plates.

Description

technical field [0001] The invention relates to the field of holographic anti-counterfeiting printing, in particular to a UV curable coating for imposing and replicating holographic information patterns and a method for using the coating. Background technique [0002] One of the most important processes of molded holographic technology is to make a holographic molded master. In the mass production process of molded holographic products, the holographic molded master is required to have a larger size, that is, a wide holographic molded master. Under the prior art, the manufacturing method of the wide-width holographic molded template is to directly emboss the holographic pattern on the small-sized holographic molded template onto the plastic sheet through an imposition machine, and then electroform the plastic sheet after metallization to obtain The wide-width holographic molded master plate is recast to obtain a wide-width holographic molded template. Because small-sized sp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09D167/06C09D175/14C09D7/12B41C1/00

Inventor 徐晓光魏家新郑成赋周毅

Owner 湖北华工图像技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com