Quasicrystal-containing magnesium alloy with high corrosion resistance and preparation method and application thereof

A technology for corrosion resistance and magnesium alloys, applied in the field of magnesium alloys, can solve the problems of poor corrosion resistance of magnesium alloys, and achieve the effects of high corrosion resistance, low density and high corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] The preparation method of the high-corrosion-resistant magnesium alloy of the present invention includes introducing a quasi-crystalline phase into an alloy matrix and subsequent homogenization treatment. The specific steps of its specific smelting and casting and subsequent homogenization treatment are as follows:

[0040] 1) Drying and preheating: the drying temperature of conventional auxiliary materials (covering agent / refining agent) is 120-180°C; the preheating temperature of various ingredients and casting molds is 150-300°C; Slag spoons, bell jars, casting spoons, etc.) are cleaned and preheated in a molten washing flux at 700-740°C.

[0041] In the present invention, the covering agent can be a mixture of LiCl and LiF, wherein the weight ratio of LiCl and LiF is (3:1)-(4:1), and their weight sum accounts for 2-4% of the total weight of the charge. In addition, the refining agent may be LiBr.

[0042] 2) Melting of magnesium ingots: set the temperature at 720-...

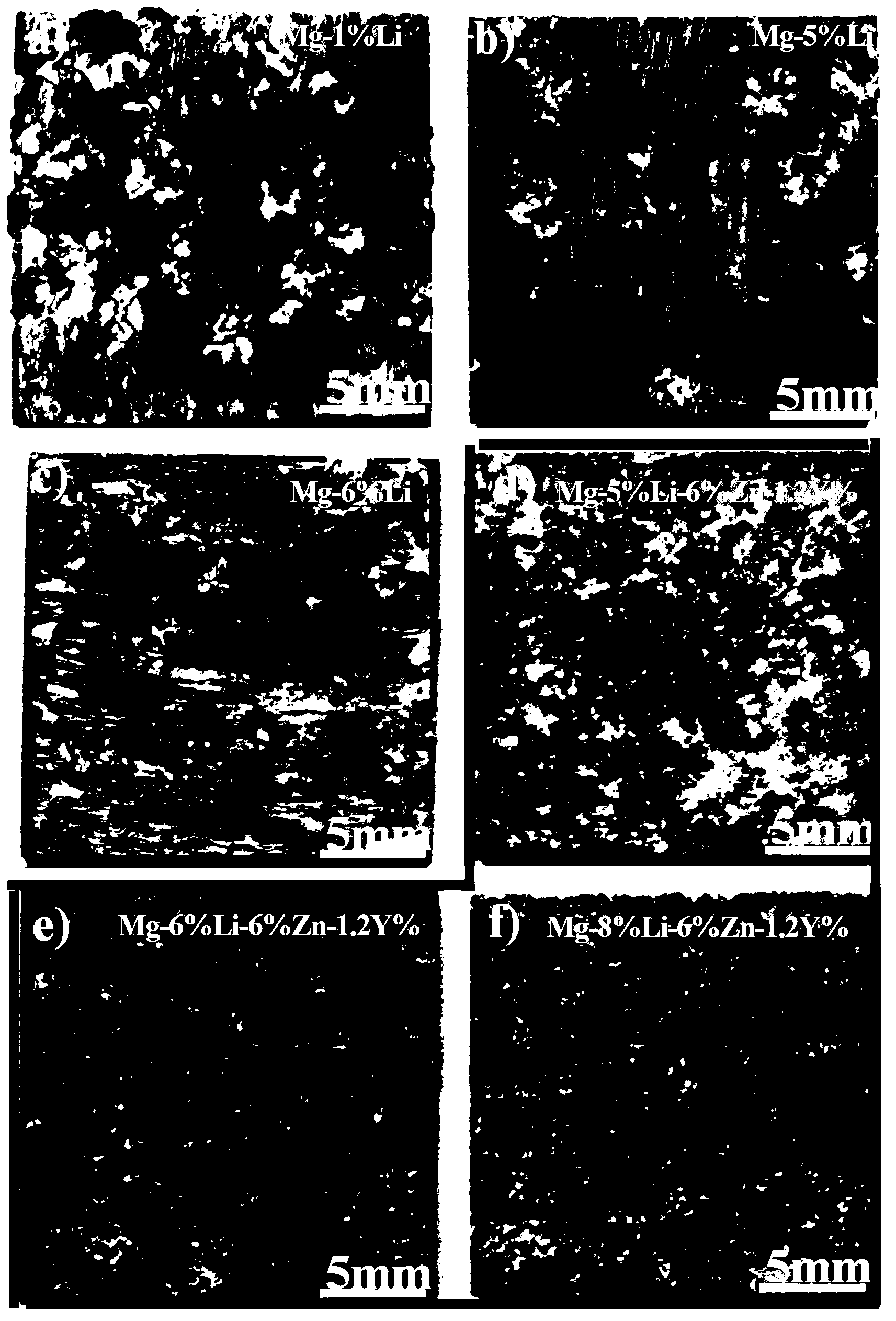

Embodiment 1

[0051] Ⅰ), alloy composition

[0052] 15 kg of Mg-Li-Zn-Y magnesium-lithium alloy materials are configured according to the following proportions. ) 750 grams and the balance of magnesium (Mg).

[0053] Ⅱ), alloy smelting and casting

[0054] The alloy is smelted in a 15 kg capacity crucible and electric resistance furnace. The crucible and casting molds are made of mild steel. Taking Example 1 as an example, the smelting and casting process of the alloy will be described in detail below.

[0055] 1) Set the target temperature of the crucible to 720°C and start heating; then preheat various ingredients such as pure magnesium, pure zinc, magnesium-yttrium intermediate alloy, and pure lithium in an oven to 150°C, and at the same time will account for 2 % of the covering agent (the covering agent uses LiCl and LiF, and the weight ratio of LiCl and LiF is 3:1) is baked in an oven; the casting mold is preheated to 300°C in another box furnace.

[0056] 2) When the crucible hea...

Embodiment 2

[0070] The difference from Example 1 is that

[0071] Ⅰ), alloy composition

[0072] According to the following proportions, 15 kilograms of Mg-Li-Zn-Y magnesium-lithium alloy materials are weighed and taken out: lithium (Li) 1200 grams, zinc (Zn) 900 grams, magnesium-yttrium master alloy (Mg-24wt%Y ) 750 grams and the balance of magnesium (Mg).

[0073] Ⅱ), alloy smelting and casting

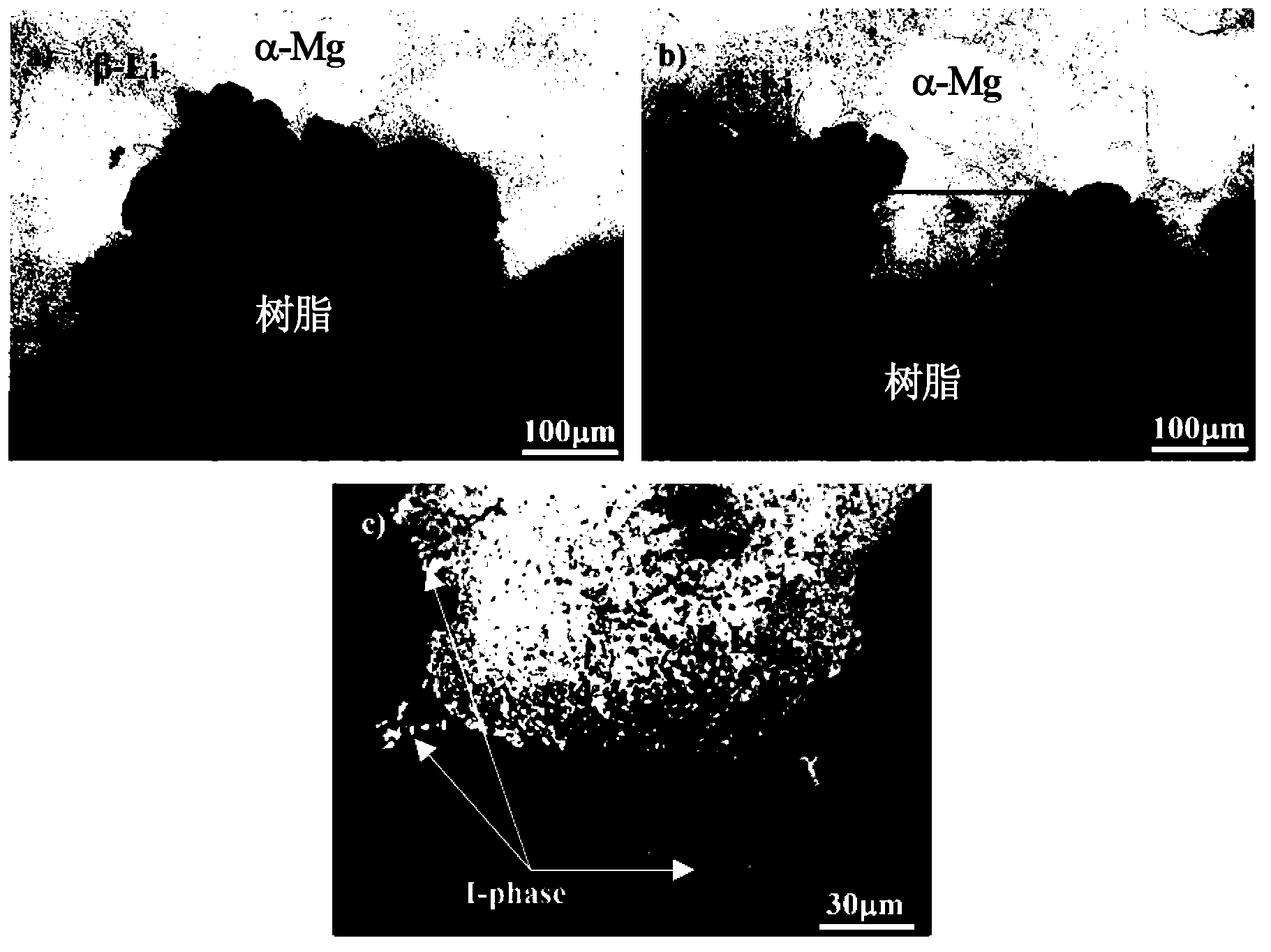

[0074] With reference to the smelting and casting of Example 1, the finally obtained Mg-Li-Zn-Y magnesium-lithium alloy is a quasi-crystalline dual-phase magnesium-lithium alloy in the α-Mg and β-Li dual-phase region, and by weight percentage, its The components and their contents are as follows: lithium content is 8%; zinc content is 6%; yttrium content is 1.2%; magnesium content is the balance balance.

[0075] Ⅲ), homogenization treatment

[0076] The ingot was homogenized at 360°C for 6 hours to eliminate the segregation of alloying elements and fully dissolve low-melting phases such as M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion potential | aaaaa | aaaaa |

| Corrosion current | aaaaa | aaaaa |

| Corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com