Four-row cylindrical roller bearing for rolling mill

A cylindrical roller bearing and rolling mill technology, applied in the field of bearings, can solve the problems of poor lubrication effect and low bearing strength, and achieve the effects of sufficient lubrication, good lubrication and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

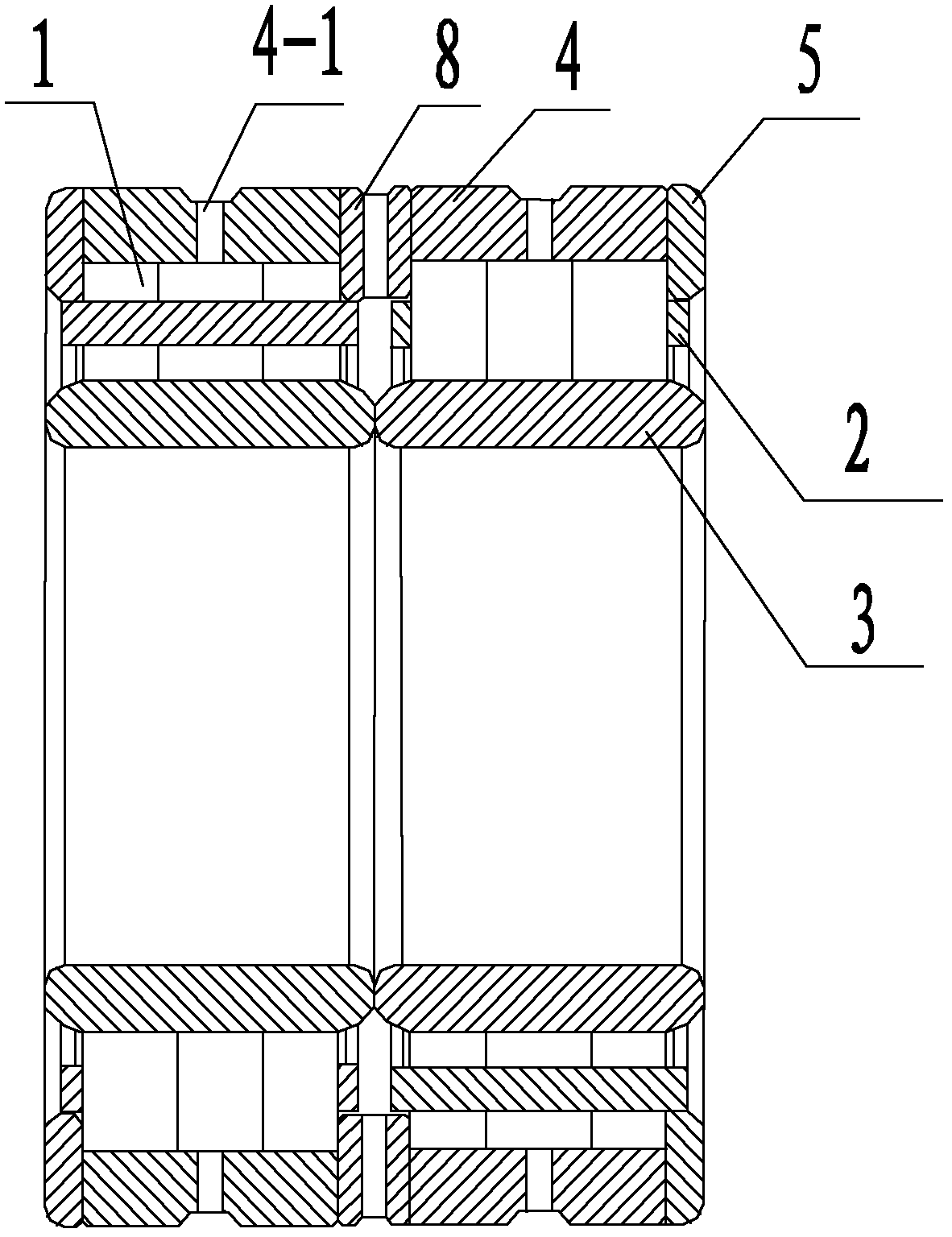

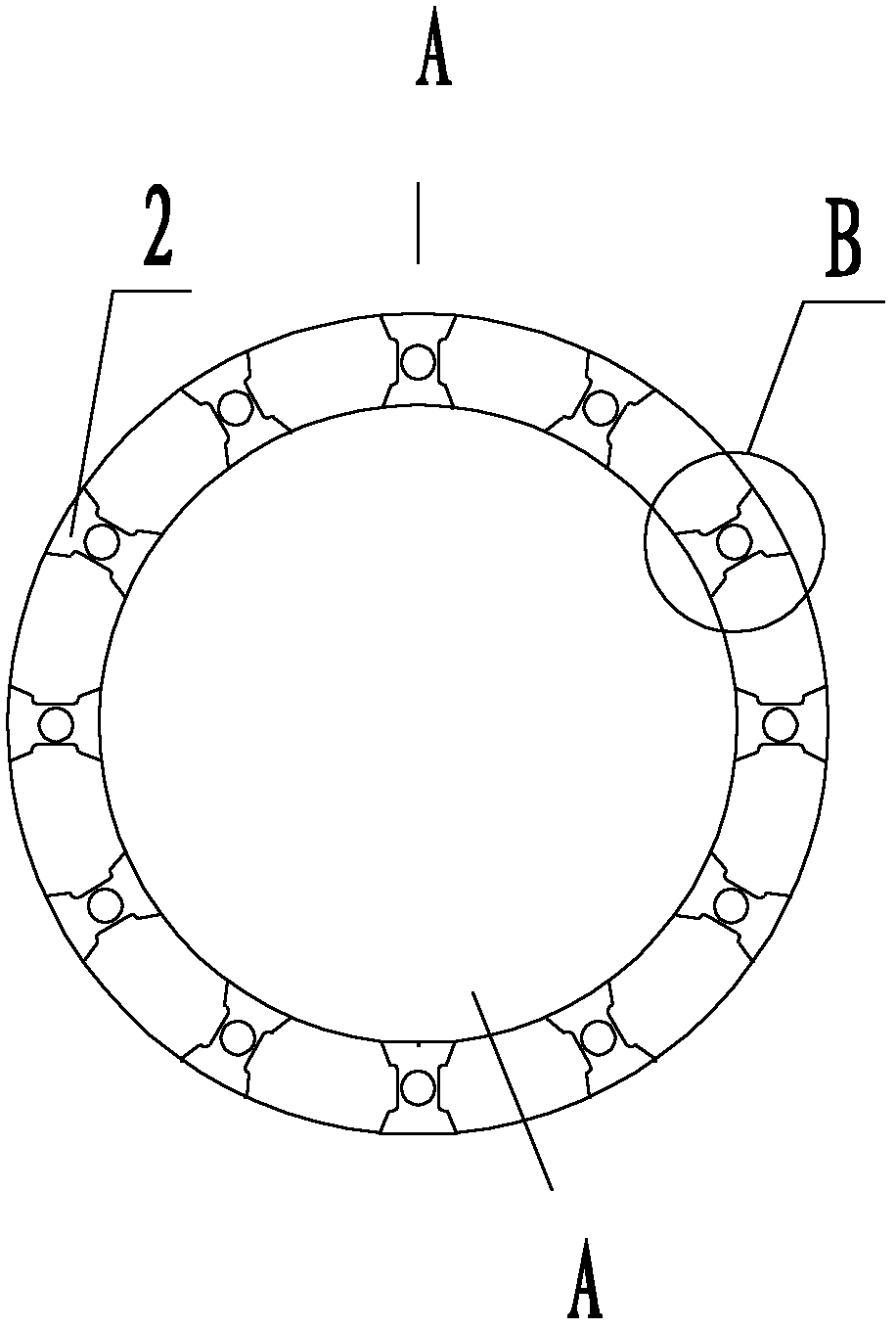

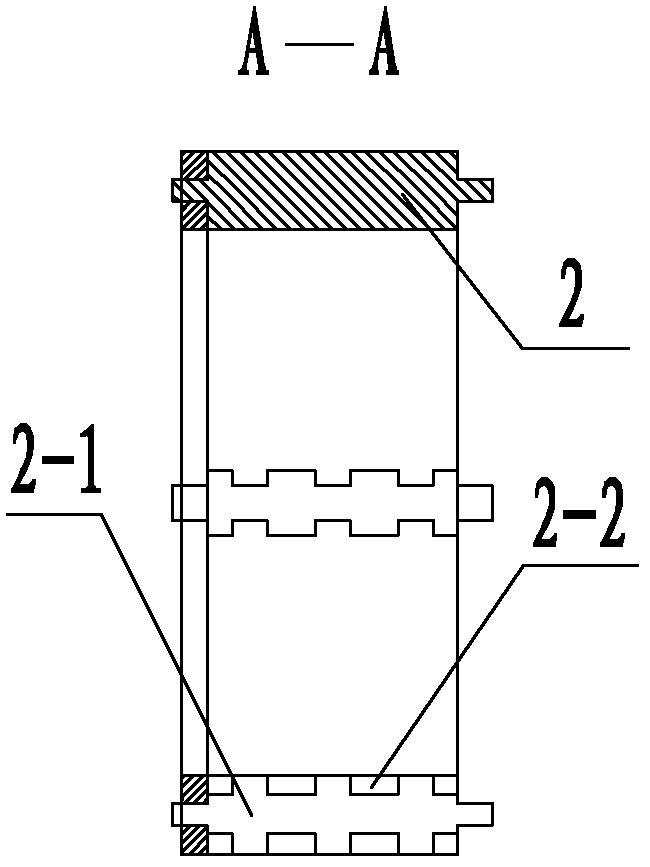

[0017] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0018] like figure 1 like figure 2 image 3 Figure 4 Figure 5 The shown four-row cylindrical roller bearing for a rolling mill consists of two identical bearing cages juxtaposed on the bearing inner ring 3, and the two bearing cages are provided with corresponding bearing outer rings 4, and the two bearing outer rings A mid-range ring 8 is arranged between the rings 4, two retaining rings 5 are arranged on the outer sides of the two bearing outer rings 4, and two bearing outer rings 4 are provided with lubricating holes 4-1 for filling lubricating oil;

[0019] In the bearing cage, there are freely rotatable rollers 1 clamped between two adjacent pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com