Steel pipe

A technology for steel pipes and butt-jointed steel pipes, which is applied in the direction of pipes, branch pipelines, pipeline protection, etc., can solve the problems of high cost and difficulty in manufacturing seamless steel pipe layers, and achieve the effects of reducing manufacturing costs, low cost and simple manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

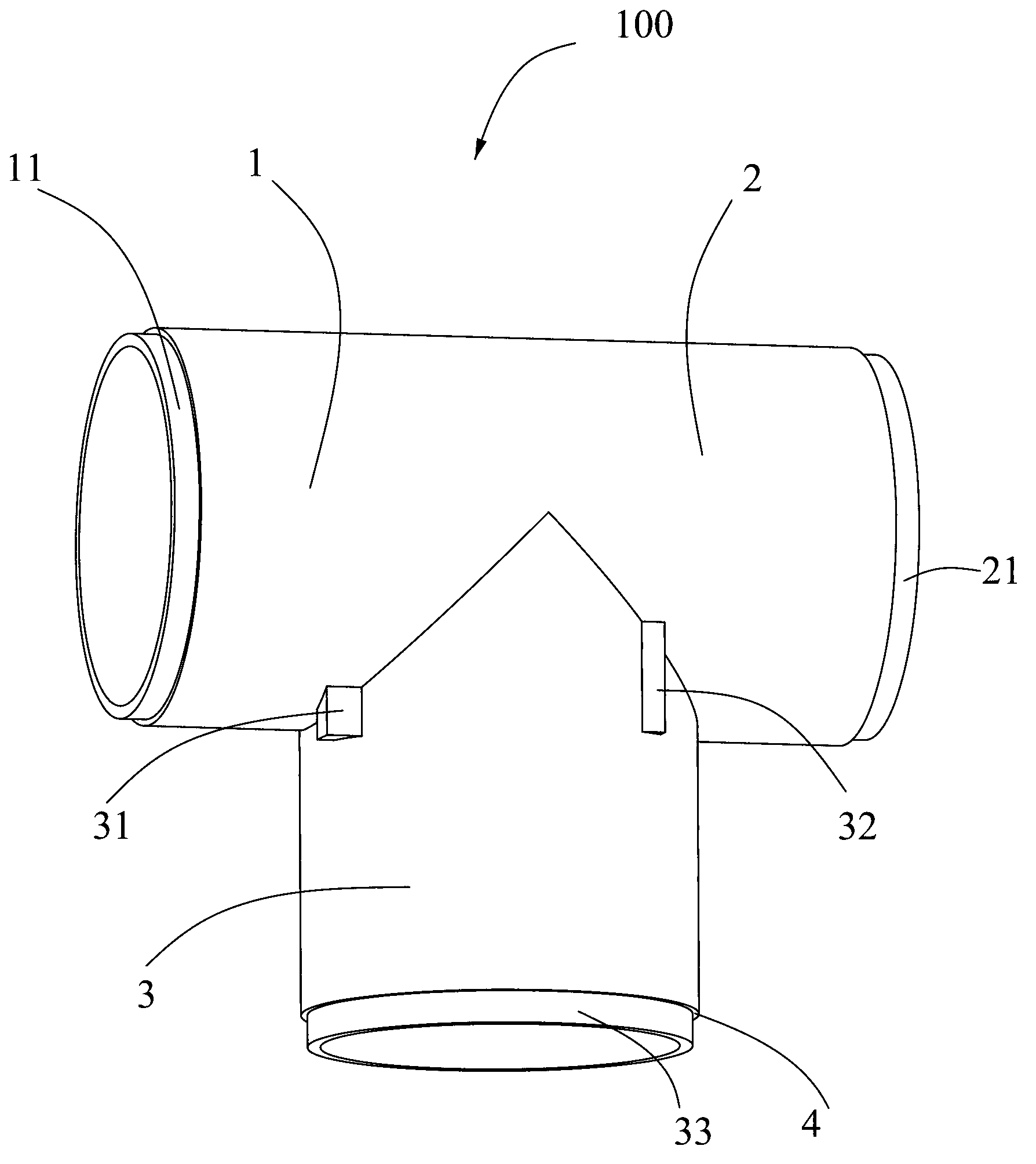

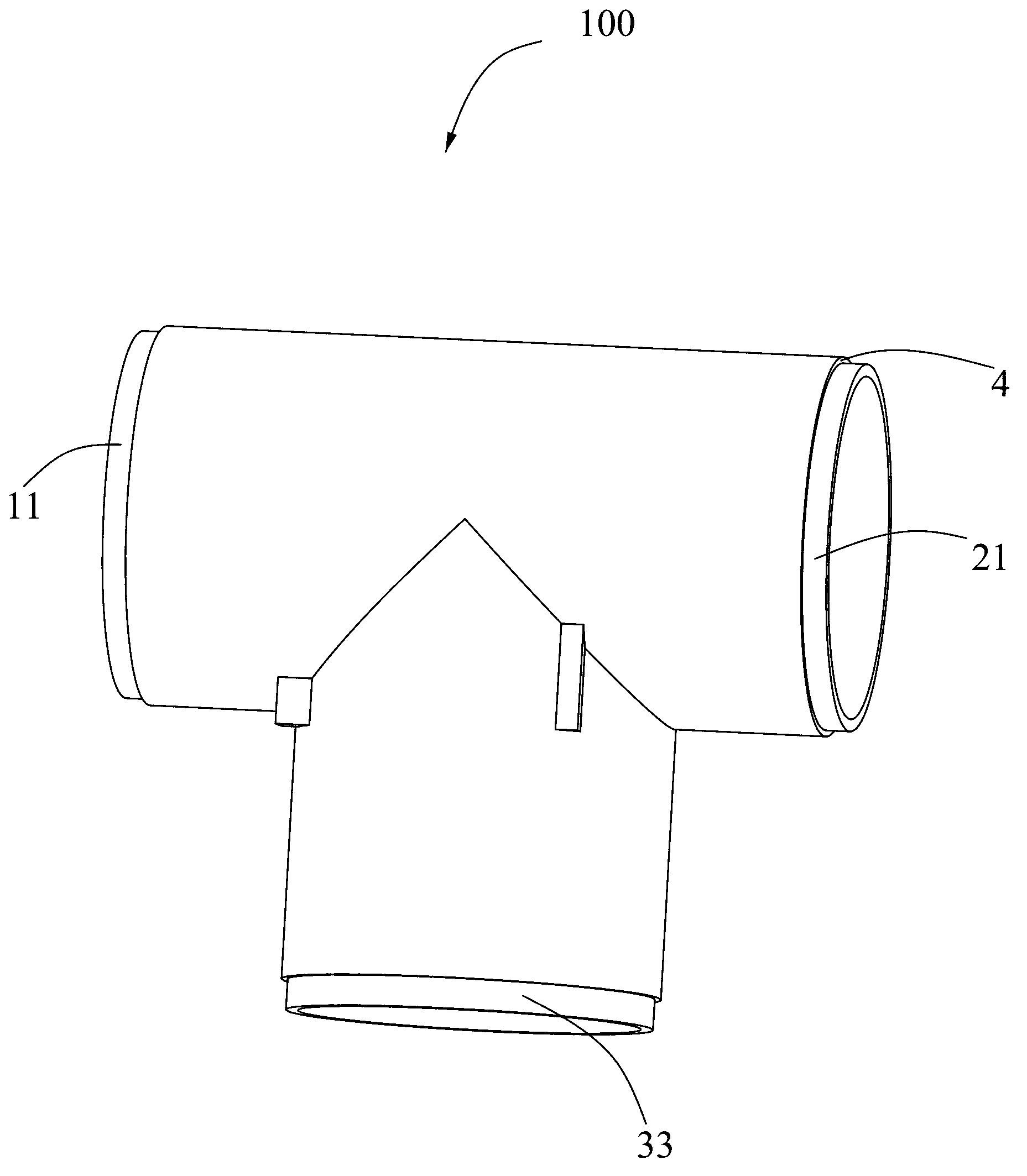

[0011] Such as Figure 1 to Figure 2 Shown is a steel pipe 100 in accordance with the present invention. The steel pipe 100 is a large steel pipe and can be used in urban sewer pipes, oil, natural gas, steam heating, hydropower stations, sewage treatment plants, thermal power plants, water supply and drainage and other occasions.

[0012] Such as figure 1 As shown, the steel pipe 100 is roughly T-shaped, including a first through pipe 1, a second through pipe 2, and a third through pipe 3, the first through pipe 1 and the second through pipe 2 are located on the same horizontal line, and the The first through pipe 1 and the second through pipe 2 are respectively located at two ends of the third through pipe 3 . Paint 4 is sprayed on the outer walls of the first through pipe 1, the second through pipe 2, and the third through pipe 3, and the paint 4 is black paint. The free end of the first through pipe 1 is provided with a first connecting portion 11 connected to the butt st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com