Ammonia-process flue gas desulfurization hydraulic stirring system and operation method thereof

A stirring system and desulfurization liquid technology, which is applied in the field of wet flue gas desulfurization, can solve the problems of slurry deposition and poor stirring effect, and achieve the effect of good stirring effect, low engineering investment cost, and high reliability of system stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

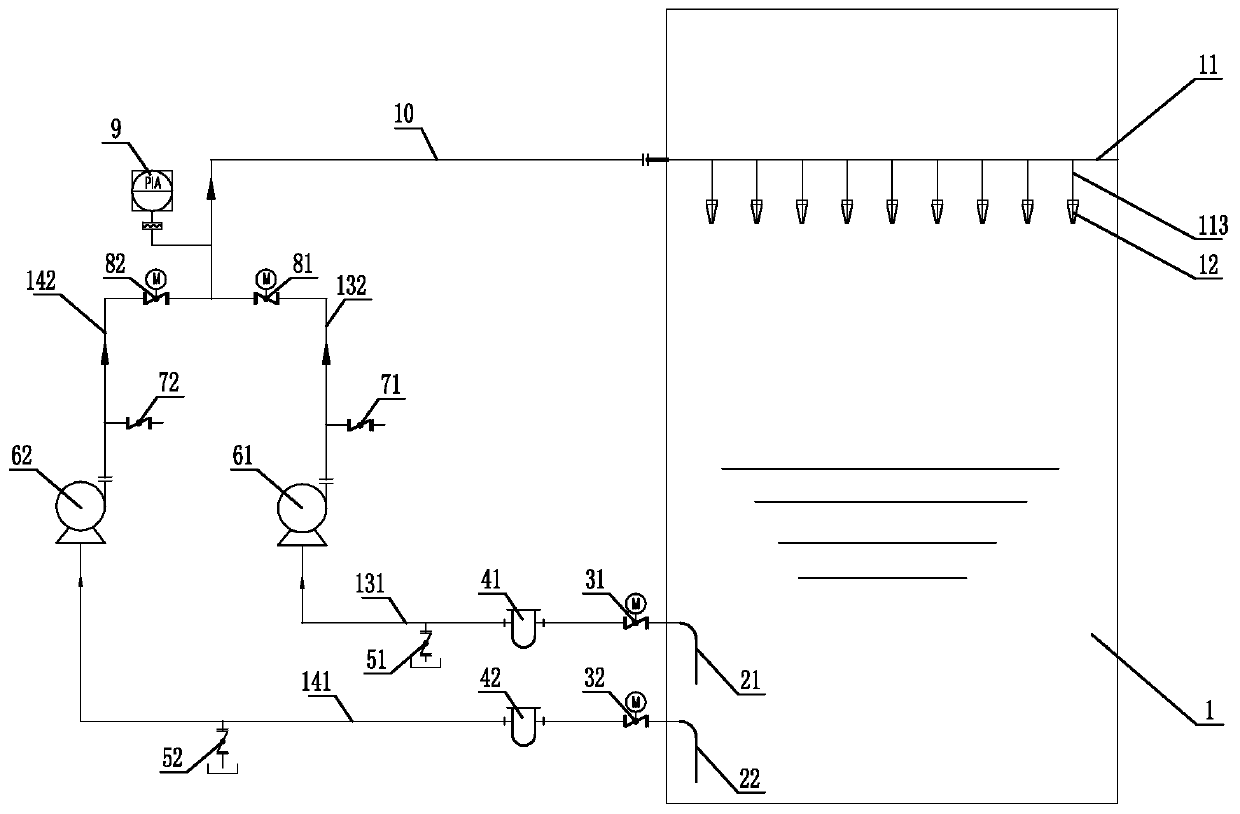

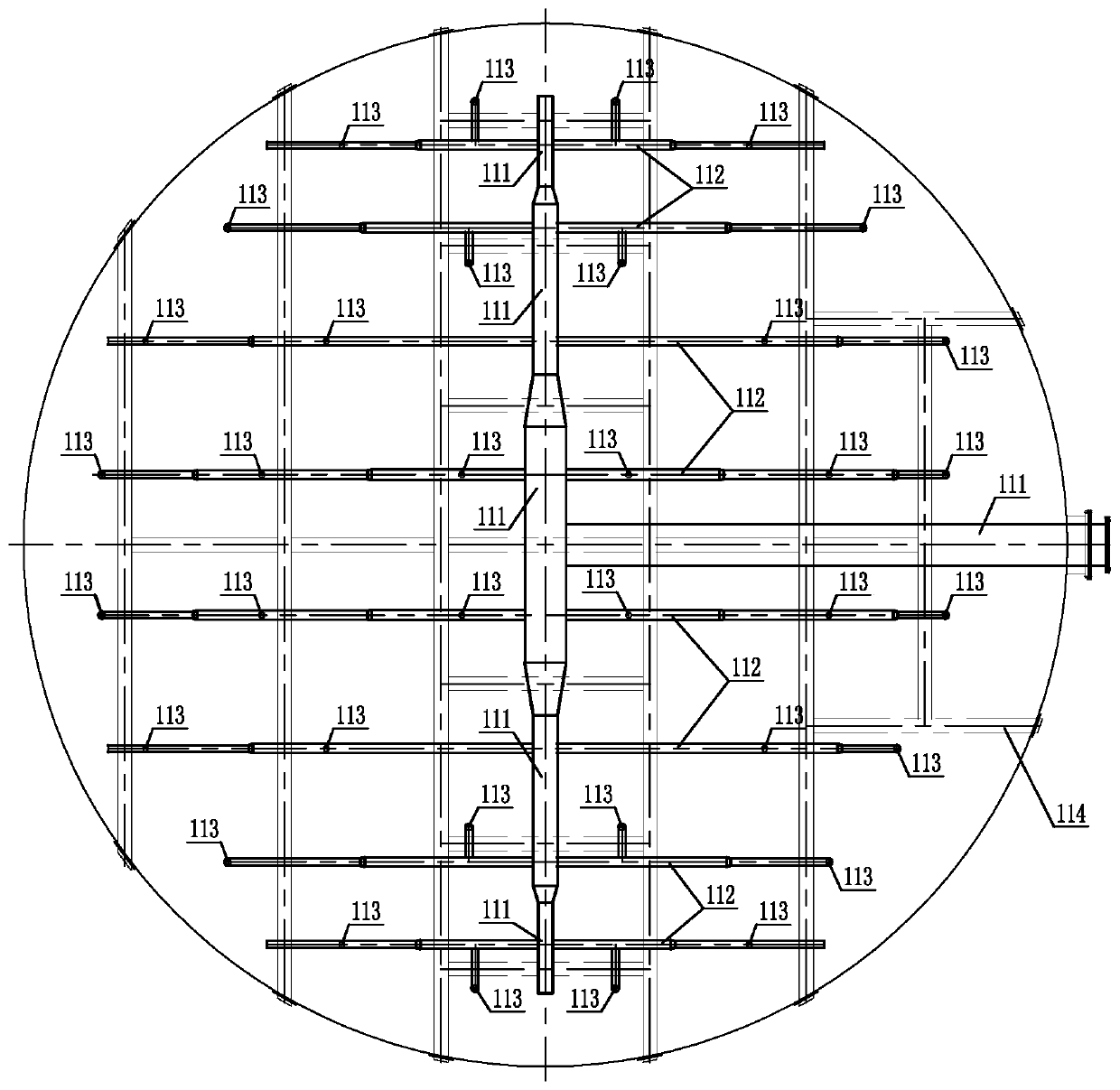

[0070] Implementation case: Taking the hydraulic stirring system of an ammonia flue gas desulfurization project as an example, the pressure level of the system is PN10, and the diameter of the concentration section 1 of the desulfurization tower is 15m; the specifications of the casing, the inlet electric switch valve, and the basket filter are all The specification of the inlet vent valve is DN50; the flow rate of the hydraulic stirring pump is Q=1700m³ / h, and the head H=23m; the specification of the outlet flushing water valve is DN50; the specification of the outlet electric switch valve is DN600; the pressure transmitter The specification of the connecting pipe 10 is DN700 / DN600 / DN50; the diameter of the disturbance distribution main pipe 111 is changed from DN600 to DN350 and then changed to DN200, and the disturbance distribution horizontal branch pipe 112 is changed from DN150 to DN125 and then changed to DN100, the specification of the disturbance distribution vertical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com