High-efficiency heat-absorption energy-storage heat exchanger

An exchanger and energy storage technology, applied in the fields of heat exchangers, high-efficiency heat absorption, and energy storage, can solve problems such as product life reduction, energy waste, and burner damage, achieve large market value and economic value, and improve overall energy efficiency , the effect of saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

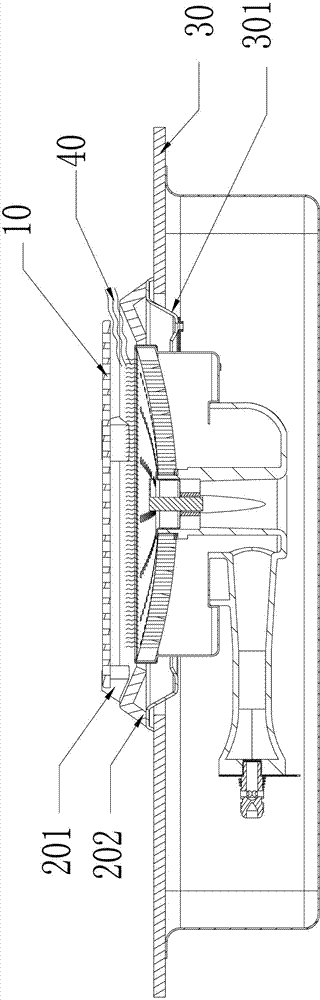

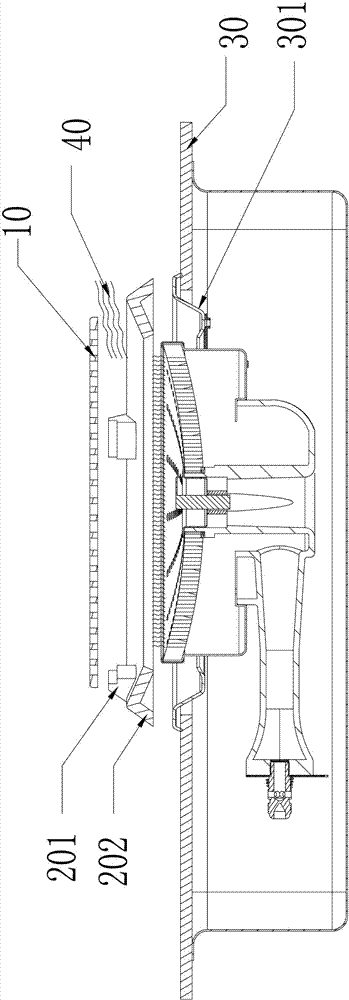

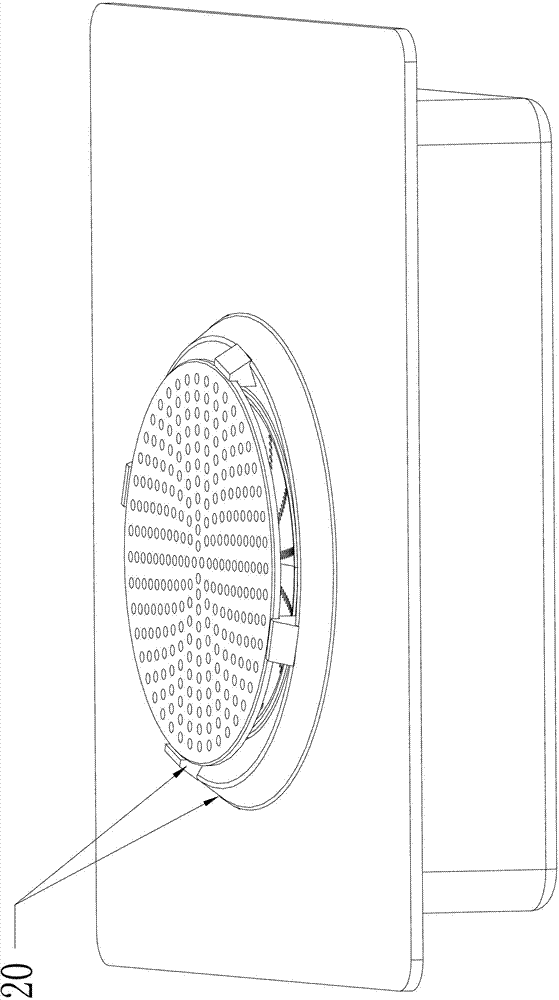

[0034] See attached figure 1 , figure 2 , image 3 , Figure 4 , Figure 11 As shown, this embodiment includes a porous honeycomb heat-absorbing energy-storage exchanger 10 located above the burner surface layer of the gas cooker, and hot flue gas directional gathering and conveying around the porous honeycomb heat-absorbing energy-storage exchanger 10 The channel 40, the porous honeycomb heat absorbing energy storage exchanger 10 is fixed or placed on the panel 30 of the gas cooker or on the bracket 301 of the fixed panel through the intermediate body 20 with the hot flue gas guiding surface.

[0035] The honeycomb hole is a two-dimensional or three-dimensional porous honeycomb heat-absorbing energy-storage exchanger 10, a directional gathering and conveying channel 40 for hot smoke, and a panel 30 of an infrared cooker. The porous honeycomb heat-absorbing energy-storage exchanger 10 is made of a flat metal material Or use one or more layers of glass-ceramics or ceramics...

Embodiment 2

[0039] see Figure 5 , Figure 6, the other structure of this embodiment is the same as that of Embodiment 1, and the intermediate body 20 is also composed of a supporting foot 201 and a guide ring 202, however, its supporting foot 201 is an independent supporting body, and the porous honeycomb heat-absorbing energy storage exchanger 10 Placed or fixed on one end surface of the supporting foot 201, the other end of the supporting foot 201 is supported on the guide ring 202, and the guide ring 202 is placed or fixed on the panel 30 of the gas cooker or fixed on the panel support 301, said The guide ring 202 is formed with a hot flue gas guide inclined surface, and the gap between the hot flue gas guide inclined surface and the porous honeycomb heat absorbing energy storage exchanger 10 forms a hot flue gas directional gathering conveyance channel 40 .

Embodiment 3

[0041] see Figure 7 , the other structure of this embodiment is the same as that of Embodiment 1, and the intermediate body 20 is also composed of supporting feet 201 and guide rings 202, however, the supporting feet 201 are integrally formed on the lower end surface of the porous honeycomb heat-absorbing energy storage exchanger 10 , the soles of the supporting feet 201 are supported on the guide ring 202, and the guide ring 202 is placed or fixed on the panel 30 of the gas cooker. The guide ring 202 is formed with a hot flue gas diversion slope, and the hot flue gas The gap between the guide slope and the porous honeycomb heat-absorbing energy-storage exchanger 10 forms a hot flue gas directional gathering conveyance channel 40 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com