Under-voltage protection circuit and high-voltage integrated circuit

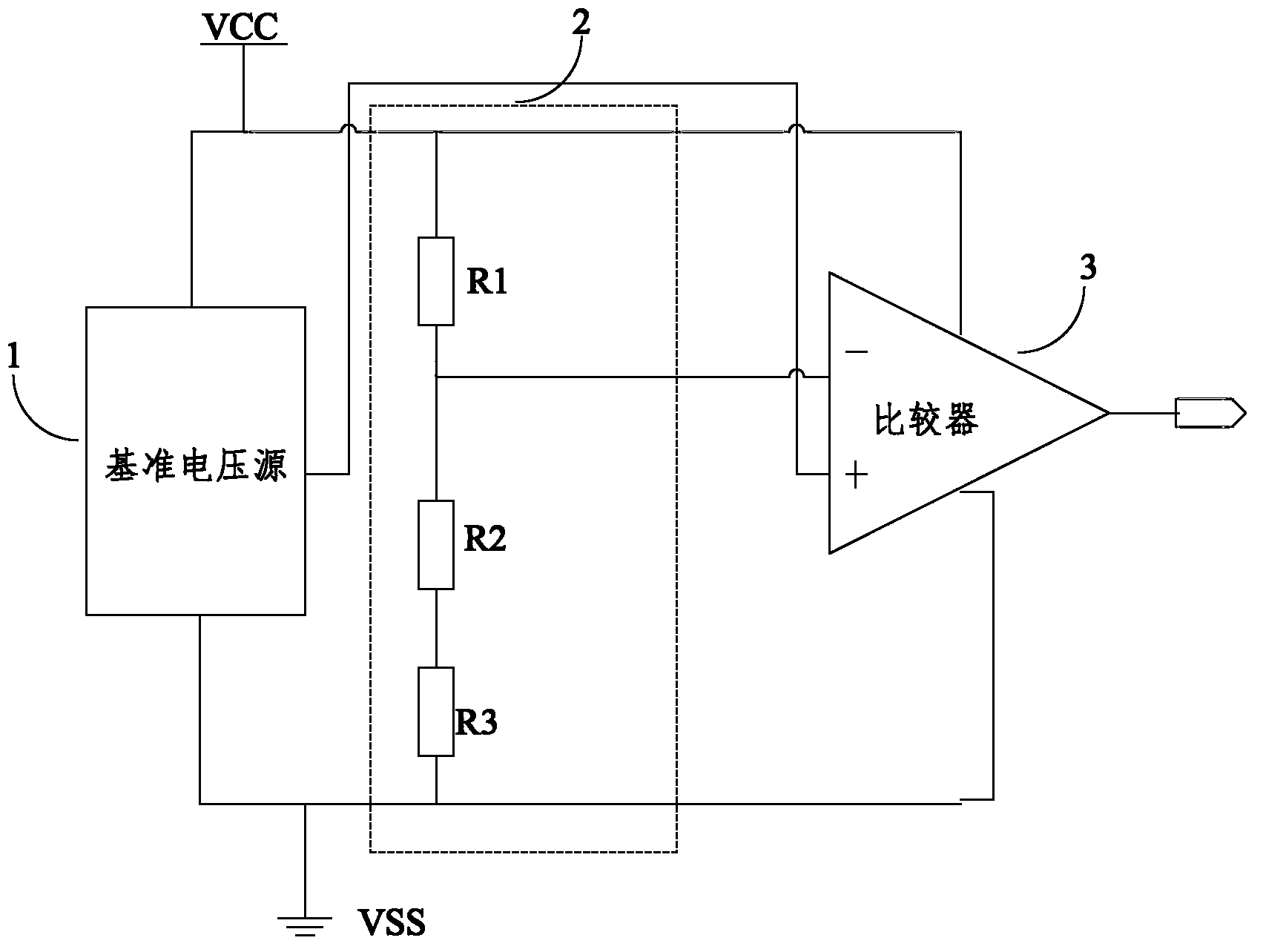

An undervoltage protection and circuit technology, applied in the field of circuits, can solve the problems of complex circuit design process, slow response time, and many components, and achieve the effects of simple design, faster response time, and fewer components used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

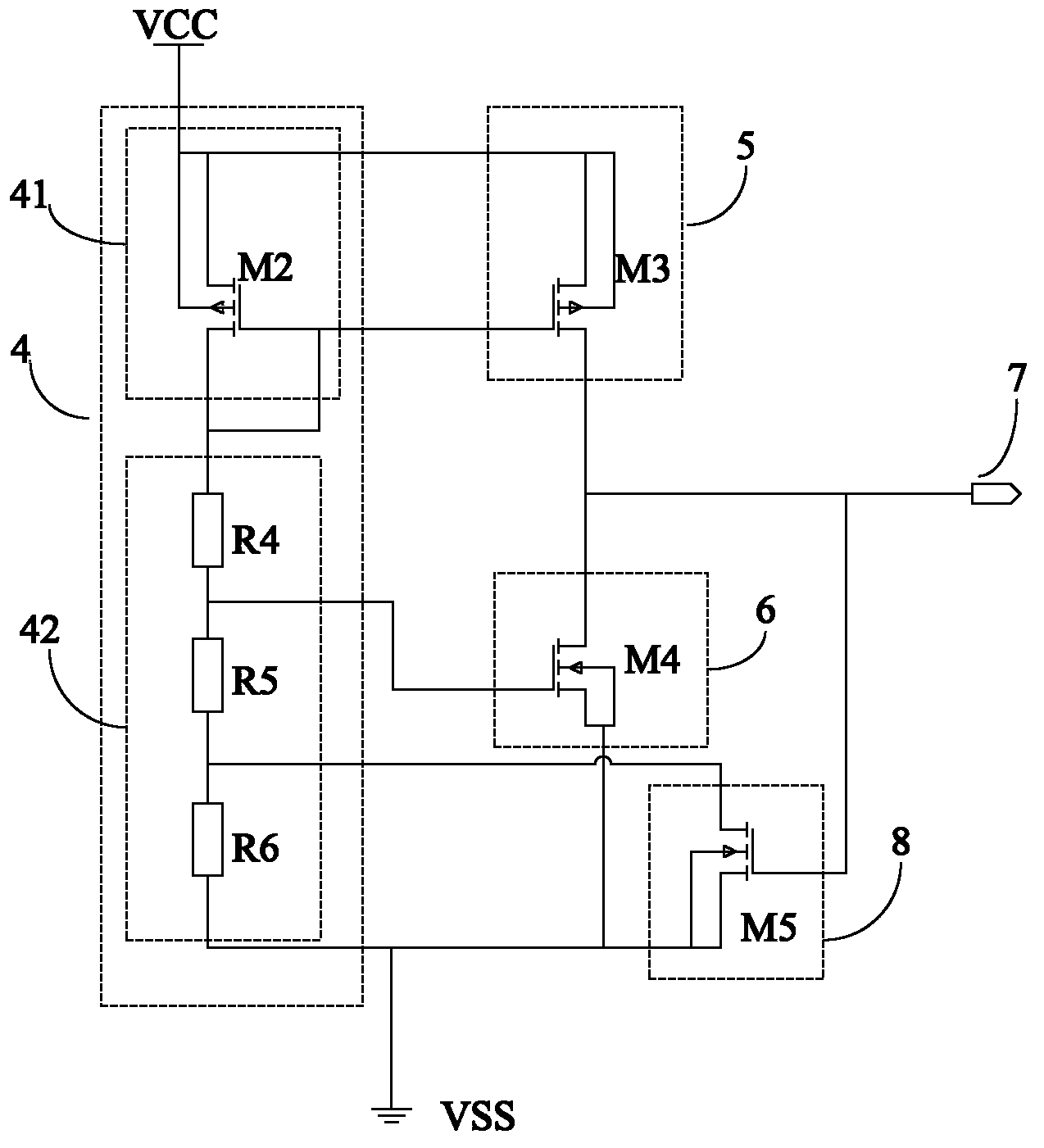

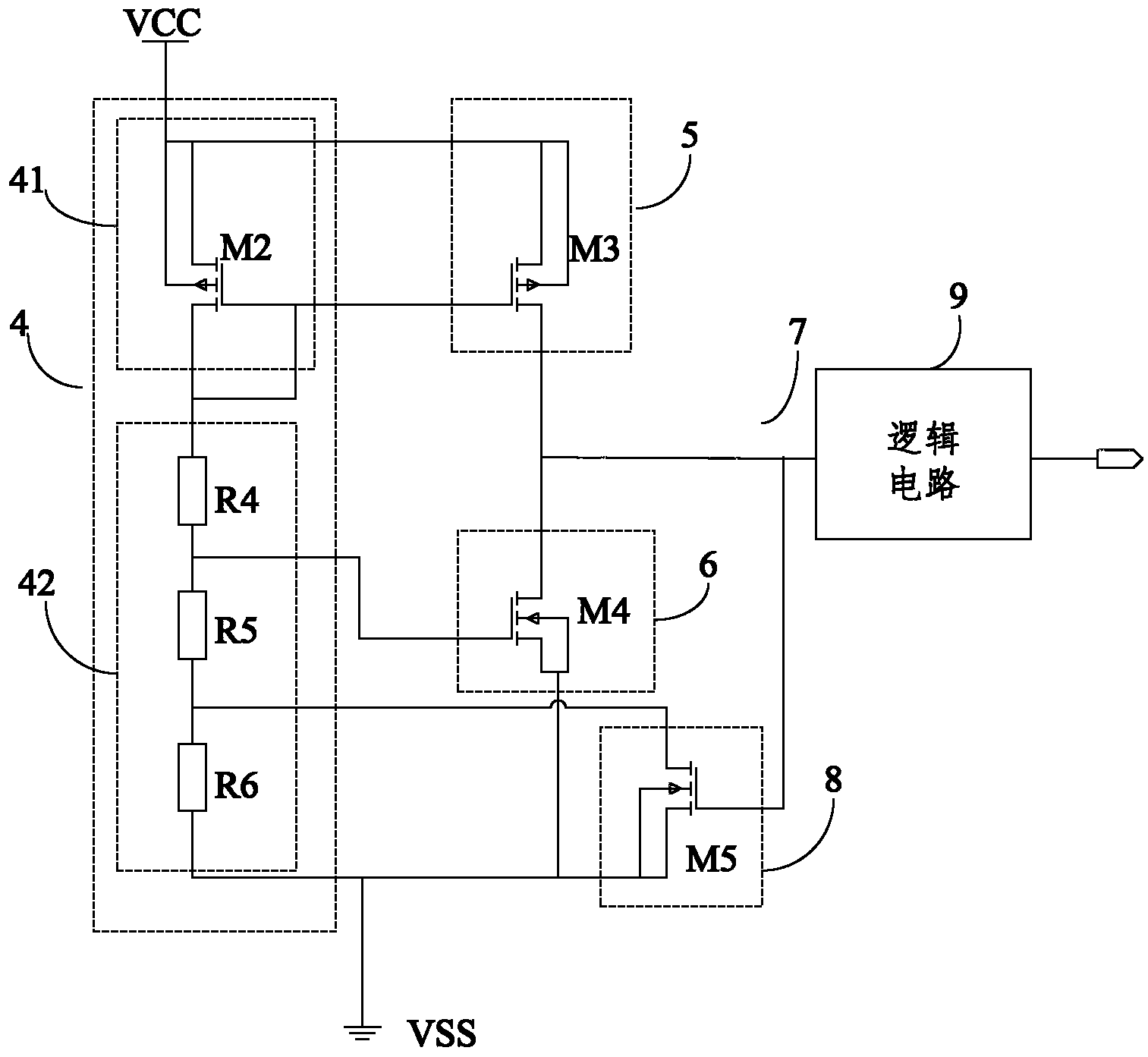

[0041] Such as figure 2As shown, the undervoltage protection circuit provided in this embodiment includes a voltage divider network 4, a pull-up circuit 5, an undervoltage protection signal output control switch 6, and an undervoltage protection signal output terminal 7. The voltage divider network 4 includes a driving power supply Sampling element 41 and voltage dividing element 42, described driving power sampling element 4 is connected with driving power VCC, is used for collecting driving power VCC; Described voltage dividing element 42 is connected with described driving power sampling element 41, is used for driving power The driving power supply VCC collected by the sampling element 41 is divided to output a second voltage signal to control the disconnection and conduction of the undervoltage protection signal output control switch 6; the pull-up circuit 5 is connected between the driving power supply and the Between the undervoltage protection signal output control sw...

Embodiment approach

[0042] As an implementation, the driving power sampling element 4 is a first MOS transistor M2, the substrate and source of the first MOS transistor M2 are connected to the driving power VCC, and the drain of the first MOS transistor M2 and the gate are respectively connected to the voltage dividing element 42; the first MOS transistor M2 is specifically a PMOS transistor (positive channel Metal Oxide Semiconductor, P-type metal oxide semiconductor transistor).

[0043] As an implementation, the voltage dividing element 42 includes a first resistor R4, a second resistor R5 and a third resistor R6 connected in series in sequence, and the first resistor R5 is respectively connected to the drain of the first MOS transistor M2 connected to the gate, the third resistor R6 is grounded, an output terminal connected to the undervoltage protection signal output control switch 6 is formed between the first resistor R4 and the second resistor R5, and is used to output the second voltage ...

Embodiment 2

[0053] Such as Figure 7 As shown, the present invention also proposes a high-voltage integrated circuit, including a driving power supply 10, a plurality of electronic components 12, a control switch 11 and an undervoltage protection circuit 13; the driving power supply 10 is connected to the control switch 11 for providing work Power supply; the control switch 11 is connected to the plurality of electronic components 12 to control the operation of the plurality of electronic components 12; the undervoltage protection circuit 13 is connected to the driving power supply 10 and the control switch 11 respectively for driving The size of the power supply outputs an undervoltage protection signal to control the on and off of the control switch 11 .

[0054] The undervoltage protection circuit 13 is the undervoltage protection circuit described in Embodiment 1, and the driving power supply 10 is the driving power supply VCC described in Embodiment 1, which will not be described in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com