DHA powder grease with soluble dietary fiber as wall materials and preparation method thereof

A technology of dietary fiber and powdered oil, applied in the field of food additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

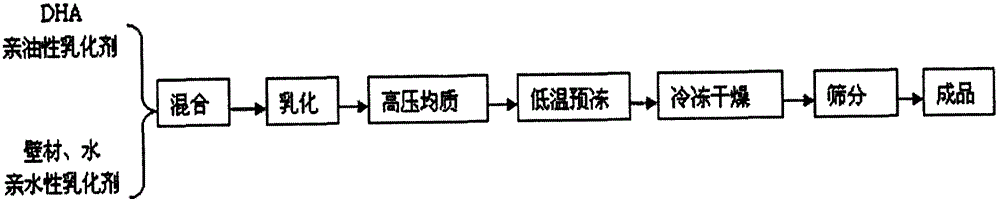

Method used

Image

Examples

Embodiment 1

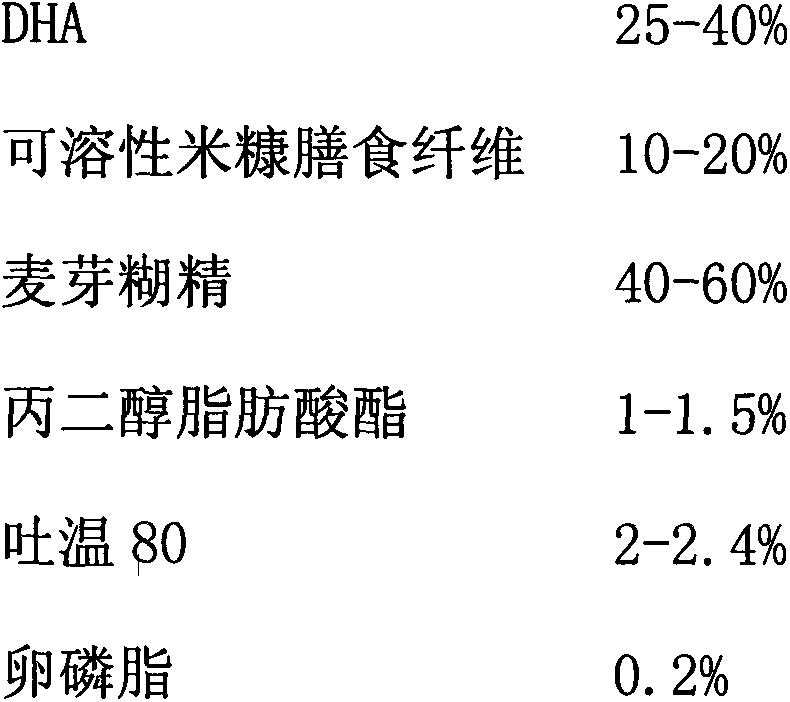

[0029] a. Preparation of oil phase liquid: Weigh 25kg of DHA and place it in a hot and cold cylinder, keep warm at 45-50°C for 35r / min and stir; then weigh 1.2kg of propylene glycol fatty acid ester and 0.15kg of lecithin according to the formula, and continue to keep warm and stir to prepare oil phase liquid.

[0030] b. Preparation of water phase liquid: Weigh 12kg of soluble rice bran dietary fiber, 40kg of maltodextrin, 802.1kg of Tween and 2kg of compound stabilizer, add 600kg of pure water and put it in another cold and hot cylinder, keep it warm at 50-65℃ for 35r / min stirring to prepare an aqueous phase liquid.

[0031] c. Stirring emulsification: pump the oil phase liquid into the water phase liquid, and add water to adjust the total solid content of the mixed liquid to about 30%, the HLB value is 13.2, keep stirring at 50-60°C for 20 minutes.

[0032] d. High-pressure homogenization: The above-mentioned emulsion is homogenized twice by a valve-type high-pressure hom...

Embodiment 2

[0037] a. Preparation of oil phase liquid: Weigh 40kg DHA and place it in a hot and cold cylinder, keep it warm at 45-50°C for 35r / min and stir; then weigh 1.4kg of propylene glycol fatty acid ester and 0.2kg of lecithin according to the formula, continue to keep warm and stir to prepare oil phase liquid.

[0038] b. Preparation of water phase liquid: Weigh 17kg of soluble rice bran dietary fiber, 60kg of maltodextrin, 802.4kg of Tween and 2kg of compound stabilizer, add 800kg of pure water and put it in another cold and hot cylinder, keep it warm at 50-65℃ for 35r / min stirring to prepare an aqueous phase liquid.

[0039] c. Stirring emulsification: pump the oil phase liquid into the water phase liquid, and add water to adjust the total solid content of the mixed liquid to about 30%, the HLB value is 13.2, keep stirring at 50-60°C for 20 minutes.

[0040] d. High-pressure homogenization: The above-mentioned emulsion is homogenized twice by a valve-type high-pressure homogeni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com