A kind of production process of copper strip for photovoltaic solar energy

A photovoltaic solar energy and production process technology, which is applied to the production process field of copper strips for photovoltaic solar energy, can solve the problems of difficult processing, high requirements on performance, tolerance and surface quality, and difficulty in obtaining copper strips, and achieves excellent electrical and thermal conductivity, The effect of good comprehensive mechanical properties and excellent surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

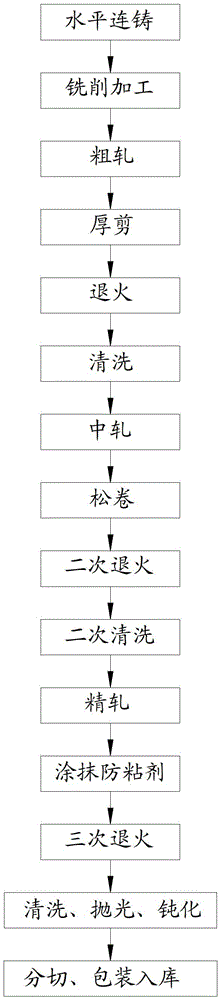

Image

Examples

specific Embodiment

[0033] Firstly, high-quality high-purity cathode copper is selected as raw material, followed by smelting, component analysis, heat preservation, and drawing casting processes. The temperature during smelting is controlled between 1180°C and 1220°C, and its composition is analyzed at the same time to ensure that each component is in the preset range. Within the range, the holding temperature is controlled at 1150°C to 1200°C. Finally, a slab with a thickness of 17.5mm is obtained by drawing casting. The content of Cu+Ag in the slab is ≥99.98%, and the oxygen content is ≤10ppm. Conductivity ≥ 100%IACS, in line with TU0 or TU1 standards. Then mill the upper and lower surfaces in the direction of the thickness of the slab to remove the casting defect layer with defects such as pores, inclusions, and cold shuts on the surface of the slab. Double-sided milling can be used for milling, and the blade is made of hard alloy YG8. Inlaid inserts, the milling depth of one side is 0.6mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| oxygen content | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com